Maximize your experience: CAMX 2025 exhibit previews, Part 1

This list of 90+ exhibitor previews solicited by CW offers a glimpse into the various technologies, emerging trends and solutions attendees should look for on the CAMX show floor.

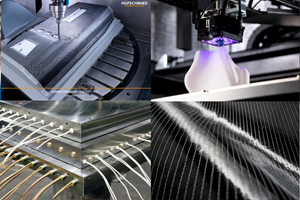

Sources (clockwise) | Broetje-Automation, Additive Engineering Solutions (AES), UD-CCM and Abaris Training Resources

This year’s Composites and Advanced Materials Expo (CAMX) promises to be an unmissable gathering for professionals in the composites and advanced materials industry. With hundreds of exhibitors showcasing the latest in materials, equipment and processes, attendees have a unique opportunity to explore emerging trends, connect with industry experts and discover tools that can transform their operations.

Maximizing the value of this experience requires preparation — researching exhibitors, planning booth visits and setting objectives — and ensures participants can navigate the show floor efficiently and leave with actionable insights that drive business growth. That’s why CW editors have taken the time to solicit and curate several exhibitor previews from companies that will be present at the show in Orlando. These previews, while only a small portion of CAMX’s complete exhibitor list, aim to provide additional insight into technology and service highlights so that you can come prepared and ready as soon as the exhibit hall opens. (For a complete exhibitor list, .)

Note: This is a two-part article (second one goes out Sept. 1) with exhibitor previews listed in alphabetical order. Click on hyperlinked text to learn more.

- 3M: Whether through weight reducing or strength enhancements, 3M designs its microspheres, ceramic fibers, films and LSP materials and composite resins to meet its customers application demands.

- A&P Technology: A&P Technology highlights its QISO and slit tape thermoplastic material capabilities through customer examples and industry applications.

- A+ Composites GmbH: A+ Composites is featuring thin-ply UD TPC tapes engineered with the inherent benefits of thermoplastics, but with individual ply thicknesses below 50?µm and fiber volume contents up to 68%.

- Abaris Training Resources Inc: Set up in its new facility in Spark, Nevada, Abaris is highlighting its training capabilities, course offerings, and customer consultation and technical assistance.

- Accudyne Systems Inc.: From supporting civilian and DOD programs to everyday customer needs, Accudyne Systems strives to deliver production improvements over existing composites manufacturing systems.

- Additive Engineering Solutions: AES is committed to driving technological advancement and application development in 3D printing, distinguishing its diverse capabilities through several tooling examples.

- Akarmak: Turnkey Akarmak autoclaves support various composite curing needs with enhanced process control, international specification compliance and optimal heat distribution.

- AKPA Kimya Ambalaj Sanayi ve Ticaret A.S.: The phthalate- and solvents-free Akperox ST-CL200 presented by AKPA Chemicals provides a reliable, user-friendly polymerization alternative while enabling high-performance production processes.

- Allied UV: Allied UV’s comprehensive production checklist reflects its vision to deliver the most efficient, tailorable UV LED coating systems for composites manufacturers.

- Ascorium Industries: Ascorium Industries is highlighting CompoLite technologies for the production of lightweight, dimensionally stable automotive components and structures.

- Avient Corp.: Avient Corp. is bringing its latest composites innovations including Polystrand, GridCore and Hammerhead solutions.

- Belotti America Inc.: The Belotti ARC is an integrated system that rapidly and automatically manages multiple types of rivets and Time-Serts.

- Big Dog Adhesives: Big Dog Adhesives’ Sausage System redefines fabricators and manufacturers’ adhesive process, delivering control, consistency and high performance for large or detailed work.

- Breton: Breton highlights how the Hawx E2 five axis can elevate trimming, milling and drilling operations.

- Brighton Science: Explore reliable, scalable and data-driven tools by Brighton Science that address adhesion and surface quality challenges, from the Surface Analyst to BConnect.

- Broetje-Automation GmbH: From fiber to flight, Broetje-Automation innovates composites manufacturing with integrated AFP, drilling and sealing technologies.

- BYK USA: BYK USA introduces Garamite-1958, a clay-based additive optimal for applications where high anti-sag, anti-settling or anti-separation performance is required.

- Cambium: Cambium’s ApexShield 1000 system, cutting carbon/carbon production time by up to 80%, gives engineers and OEMs scaling high-temperature composite solutions a step up in survivability, processability and performance.

- Carbon Fiber Conversions GmbH: Work with Carbon Fiber Conversions, a supplier and a strategic partner, to transform carbon fiber waste into a valuable resource, strengthening both business and sustainability credentials.

- Chem-Trend LP: Chem-Trend’s 2775W represents a solution for composites manufacturers who want high performance without the operational changes required by solvent technologies.

- Coastal Enterprises: For more than 50 years, Coastal Enterprises has supported design, prototyping and composite layup applications with its Precision Board urethane tooling board and custom bonding offerings.

- Composites One: Learn more about Composites One’s comprehensive expertise, support and resources, and watch complex manufacturing processes live on the show floor.

- Concordia Engineered Fibers: Concordia Engineered Fibers exhibits its semi-consolidated towpreg innovation that reduces the bulk of commingled towpreg while maintaining a more flexible tow than fully consolidated prepreg.

- De-Comp Composites Inc: De-Comp’s blend of skilled representatives, a comprehensive suppliers base and well-rounded materials supply are at the heart of the company’s composites supply activities.

- Dieffenbacher: Dieffenbacher presents a comprehensive range of products and services geared toward construction and infrastructure applications, including customer projects, production lines, AR innovations and hydraulic presses.

- Design Concepts: Design Concepts invites attendees to learn more about its comprehensive infusion part fabrication capabilities, spanning design, engineering, tooling and composite parts manufacturing.

- Dickinson Corp.: Dickinson presents its portfolio of “metamaterials,” looking to collaborate with industry partners to demonstrate their scaled-up mechanical capabilities and potential.

- Endeavor Composites Inc: Through a reclaiming and reengineering process, Endeavor Composites creates nonwoven preforms from unused carbon fiber waste, reducing costs and environmental impact while still meeting stringent design requirements.

- Engineering Technology Corp.: Engineering Technology Corp. strives to raise the bar with precision-engineered solutions like Tape Wrappers, which are built for propulsion systems, structural components or thermal protection solutions.

- Eurovac Inc.: Eurovac’s objective is to design, develop and supply quality dust and fume extraction systems for customers, backed by a comprehensive facility, knowledgeable engineering team and growing distribution network.

- Extec Corp.: Extec is building testing capabilities with a focused lineup of composite sample prep solutions and live demos.

- Fairmat Inc.: Fairmat exhibits FairPly, a scalable, versatile material engineered from cured CFRP chips that releases 90% less manufacturing emissions and can be incorporated with a variety of other virgin material systems.

- Fibro Grats Private Ltd.: The highly controlled system highlighted by Fibro Grats is engineered to precisely dilute concentrated acid solutions and transfer them into various containers.

- French Oil Mill Machinery Co. (TMP): Learn how a custom press from French enhances the composite molding process, equipped to adhere to application/requirement needs.

- Freudenberg Performance Materials: Global technical textiles company Freudenberg Materials presents its portfolio of surfacing veils and Enka Solutions 3D polymeric filament structures used in flow media and spacers.

- Hawkeye Industries: Hawkeye Industries exhibits Duratec, Styrosafe, Styroshield and Aqua-Buff brands for optimal composites coating, compounds and polish solutions options.

- Heatcon Composite Systems: Dual-zone hot bonders and multizone composite repair systems are a couple product options featured by Heatcon that offer flexible repair of composite structures in diverse scenarios.

- Incoa Performance Minerals: Sustainability and cost-effective manufacturing is embedded in every stage of Incoa’s InCal product line, meeting the diverse processing needs of resins, adhesives and fibers.

- James Cropper Advanced Materials: New opportunities in healthcare are unlocked with James Cropper’s Optiveil surface veil technology’s validation for use in sensitive medical environments.

- Janicki: From concept to completion, Janicki highlights its ability to bring expertise, scale and agility to tooling, parts, prototypes and assemblies production.

- Johns Manville: Johns Manville displays its portfolio of glass fiber reinforcements including MultiStar, StarRov and ThermoFlow, which were manufactured with thermoplastic and thermoset composites in mind.

- Kaneka Aerospace LLC: Kaneka Aerospace 250°F BMI prepreg tooling, developed in collaboration with Janicki Industries, elevates composite tooling capabilities.

- L&L Products: Through interactive demos, hands-on materials and chats with experts, L&L is demonstrating its composite materials portfolio, purpose-built for a diverse range of industries and applications.

- Langzauner USA Inc.: Precision and power is part of Langzauner’s engineering-driven philosophy, characterized through its high-performance press systems and turnkey automation solutions for aerospace and automotive.

- Lanulfi Moulds s.r.l.: Lanulfi Moulds, serving a diversified portfolio, is available to discuss and demonstrate how its custom RIM/RTM molds can elevate performance, shorten cycle times and reduce overall production costs.

Visit CW’s CAMX page for more info.

Related Content

Autonomous agents optimize decision flows in aerospace, composites production

CAMX 2025: With manufacturers face labor shortages, increasing product complexity and pressure to operate sustainably, Plataine’s AI Agents provide the agility and intelligence needed for real-time decision-making.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreExacting chemistry streamlines composite surface prep

CAMX 2025: Hawkeye Industries exhibits Duratec, Styrosafe, Styroshield and Aqua-Buff brands for optimal composites coating, compounds and polish solutions options.

Read MoreConcentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More