Ultrasonic welding for in-space manufacturing of CFRTP

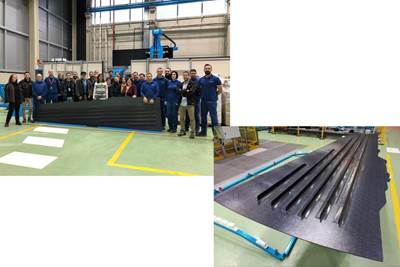

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Agile Ultrasonics has developed an advanced ultrasonic welding system that is integrated with a robotic arm. This innovation enhances precision and efficiency in welding applications. Source | Agile Ultrasonics

In-space manufacturing (ISM), the concept of producing materials and components beyond Earth’s atmosphere, emerged in the 1970s, and has since advanced from theoretical research to practical experimentation. The primary goals of ISM include reducing launch costs by fabricating parts directly in orbit, enabling on-demand production for long-duration missions and harnessing the advantages of space environments — such as microgravity and vacuum conditions — for producing materials.

Thermoplastic composites (TPC), which have seen substantial advancement in aerospace and space applications within the last decade, show potential for ISM. They provide several key advantages over conventional thermoset systems, including ease of joining and processing through melting and fusion bonding/welding, enhanced recyclability and improved fracture toughness. However, they also face a critical challenge: Achieving reliable, repeatable and automated joining of structural components under the extreme conditions prevalent in space environments.

To tackle this challenge, NASA’s (Washington, D.C., U.S.) Game Changing Development (GCD) Program, operational since 2011 under the Space Technology Mission Directorate, has initiated multiple projects exploring advanced materials and joining methodologies for in-space assembly. The program emphasizes versatility over specific flight hardware applications, aiming to enhance future mission capabilities across diverse scenarios.

One notable initiative started in October 2021, the Thermoplastic Development for Exploration Applications (TDEA), focused on examining the structural integrity, processing characteristics and in situ joining techniques of carbon fiber-reinforced thermoplastics (CFRTP). NASA pursued TPC welding, aligning with its strategic objective to advance materials and manufacturing methodologies for space exploration.

Chris Skocik, Agile Ultrasonics engineer manager, displaying a lunar tower prototype L-bracket welded at the company’s facility in Columbus, Ohio. Source | NASA/Goddard Space Flight Center Scientific Visualization Studio (lunar image), Agile Ultrasonics

“The capabilities of TPC welding can significantly streamline in-space assembly operations,” highlights Dr. Sandi Miller, a chemical engineer at NASA’s Glenn Research Center (Cleveland, Ohio, U.S.). “Instead of managing individual components like bolts and predrilled holes, the process simplifies to melting the thermoplastic and applying pressure. This approach not only enhances ease of assembly but also allows for easier construction of larger structures.”

TDEA program background

Under the TDEA framework, teams from NASA’s Glenn Research Center, Langley Research Center (Hampton, Va., U.S.), Goddard Space Flight Center (Greenbelt, Md., U.S.) and Marshall Space Flight Center (Huntsville, Ala., U.S.) conducted an in-depth investigation into the performance of TPC in lunar and orbital conditions. The research encompassed laminate processing, mechanical characterization and the evaluation of joining techniques. Various welding methods were scrutinized, including resistance, ultrasonic and induction welding. Although resistance and induction welding exhibited high mechanical strength, they also posed significant challenges related to power consumption and feasibility for space applications. In contrast, ultrasonic welding showcased robust joining capabilities that align well with robotic operations and the environmental constraints inherent in space missions.

Overview of the welding techniques and thermoplastic composite (TPC) materials assessed in NASA’s TDEA program. Source | NASA

(Columbus, Ohio, U.S.) initiated a collaborative effort with NASA under the TDEA framework in 2022, aimed at exploring the potential of the company’s ultrasonic welding technology for CFRTP. The partnership’s primary goal is not to deliver a conclusive solution, but to accumulate foundational data, refine process control methodologies and evaluate the technique’s viability for structural joining applications in space environments.

Agile’s work commenced with a series of small-scale experiments, including single-lap shear coupon tests, flat panel weld evaluations and initial single-lap shear testing. Encouraged by results that confirmed the feasibility of welding thick TPC laminates, NASA subsequently expanded its collaboration with Agile Ultrasonics to incorporate structural-scale trials and environmental validation studies.

Welding approach

Ultrasonic welding is a proven technique for joining TPC materials, especially prevalent in the automotive and consumer goods sectors (learn more about welding). Here, traditional applications generally target thin components made from low fiber-content substrates, using high-frequency vibrations to generate localized heating at the interface. Even when used in aerospace applications, conventional processes typically deploy geometric features such as energy directors or resin-rich film inserts to facilitate melting and material flow at the bondline, especially for continuous ultrasonic welding applications.

Agile Ultrasonics contends that the potential of ultrasonics remains largely untapped by traditional OEM system manufacturers. As an innovative enterprise, Agile’s strategy is to adapt the technology for underexplored application areas, informed by the properties of the composite materials at hand. The company has demonstrated that by customizing the ultrasonic stack and developing novel methodologies, it can yield results previously deemed unachievable, such as continuous ultrasonic welding without energy directors or polymer films.

A tensile test conducted on a carbon fiber-reinforced thermoplastic coupon joined through ultrasonic welding. Preliminary trials demonstrated the capability for achieving robust and consistent bonding across thick laminate structures using this testing technique. Source | NASA

“Our approach is to prioritize understanding the material properties and work backward from there,” notes Jim Stratton, president and CEO of Agile Ultrasonics. In the context of high-performance TPC, particularly those with a high fiber fraction, the central challenge lies in delivering precise heating to the material in a controlled manner, while advancing with optimal speed and pressure/force to fulfill the weld requirements.

Agile’s system is designed to achieve through-thickness heating by employing a specialized ultrasonic end effector, coupled with tailored process parameters and methodologies. This technology is adaptable across various robotic platforms and delivers programmable ultrasonic energy via modular sonotrode designs, which maintain contact with the composite surface while following the weld path.

In contrast to traditional ultrasonic welders that rely on off-the-shelf components, Agile Ultrasonics’ systems are custom-engineered to align with the thermal and mechanical properties of aerospace-grade composites. These advanced materials, including prepregs using low-melt polyaryletherketone (LMPAEK) polymer from Victrex (Cleveleys, U.K.), can contain up to 60% carbon fiber by volume and demonstrate low melt flow characteristics compared to standard TPC. Agile adjusts its ultrasonic stack and welding parameters according to the specific resin behavior, fiber architecture and laminate thickness of the components being joined.

This versatility makes the technology suitable for joining pre-consolidated plates, preforms, braided sleeves and unidirectional tape layups, offering flexibility across diverse composite formats. The technology enables meticulous control over frequency, amplitude, force and welding speed, with operational capabilities in both ambient air and vacuum environments. Typically, the system operates at 20 kilohertz and exerts force ranging from 45-150 pounds (200-670 newtons).

Material selection and characterization

The TDEA project assessed five TPC material systems to pinpoint the most viable options for application. Following rigorous testing of more than 600 coupons, the research team identified Toray Advanced Composites USA’s (Morgan Hill, Calif., U.S.) T700 carbon fiber-reinforced LMPAEK prepreg as the leading candidate.

“Our choice to advance with LMPAEK was driven by its optimal processability and the substantial material characterization data accumulated during the down-selection phase,” notes Miller. “Despite successful welding with the other materials evaluated, LMPAEK’s ability to be processed at lower temperatures than PEEK and PEKK stands out, as it minimizes residual stresses in the final components.”

A TPC L-bracket in production using automated tape laying techniques over a molded substrate ahead of ultrasonic welding to facilitate structural integrity assessments. Source | National Institute for Aviation Research (NIAR) at Wichita State University

The material testing regimen also encompassed an evaluation of outgassing properties, a critical factor for space applications. All TPC materials tested exhibited negligible outgassing levels in accordance with ASTM E595, which measures mass change of the sample and mass of collected condensed volatiles.

From 2022 to early 2024, Agile Ultrasonics’ collaboration with NASA evolved from initial small-scale feasibility studies to intricate structural evaluations. During this period, multiple design of experiments were executed to establish baseline performance metrics of weld joints across diverse materials and laminate configurations. The initial focus included single-lap shear (SLS) coupons, specifically sized at 1 × 1 inch (25.4 × 25.4 millimeter) bond areas, composed of carbon fiber-reinforced LMPAEK composites. These coupons underwent welding using Agile’s technology and were subsequently tested following standardized mechanical protocols.

Joint trials and results

A simulation model of the welded L-bracket joint, detailing the weld zones and structural configuration, facilitates the prediction of mechanical performance and informs the optimization of ultrasonic welding processes. Source | NASA

The trials used a series of ultrasonic welding techniques including plunge welding (static or spot welding of clamped parts in a fixture) and continuous ultrasonic welding methods. Iterative modifications of process cycles were carried out in collaboration with the NASA research team to enhance joint quality by investigating various interface configurations.

“While earlier ultrasonic welding process models addressed some aspects of the physics involved, they failed to encapsulate all the critical mechanisms,” remarks Andrew Bergan, analysis lead at NASA Langley Research Center. “Our modeling efforts revealed some deficiencies in conventional approaches to heating mechanisms, particularly as they relate to the melt temperature range. This insight highlighted the necessity for improved process models to more accurately predict and control heat generation during the ultrasonic welding of these advanced thermoplastic [composites].”

In terms of performance, initial tests using LMPAEK film interlayers revealed shear strengths ranging from 3-8 MPa, with predominant adhesive failure modes at the bond interface. Notably, by incorporating an LMPAEK film layer into the adherend to enhance polymer chain entanglement, the research team attained lap shear strengths of up to 2.9 ksi (20 MPa) using four layers of LMPAEK film. However, this improvement came at the expense of introducing an unpredictable and potentially catastrophic failure mode that could compromise the adherends.

By mid-2024, the initiative progressed from coupon testing to the welding of structural components. This next phase involved the welding of prototype L-brackets, structured to simulate a joint within a theoretical space framework. These components featured 60-ply, 8.59-millimeter-thick CFRTP laminates welded to 52-ply, 7.58-millimeter-thick CFRTP laminates, closely resembling those intended for use in a lunar tower designed for assembly on the Moon’s South Pole.

NASA’s structural testing apparatus assessing the integrity of ultrasonic-welded L-bracket joints. The test samples exhibit failure modes occurring in the parent laminate material rather than at the weld interface. Source | NASA

“The L-section was chosen for its structural openness, facilitating a dual-sided pressure application during welding,” explains Ken Segal, design lead at NASA Goddard Space Flight Center. “This configuration strikes a balance between structural efficiency and access for welding operations.”

During this phase, NASA selected plunge welding methodologies to further investigate, guided by considerations of part thickness and scale-up efforts. Tensile testing on the plunge-welded brackets demonstrated the highest strengths, exceeding 2.7 times the designated limit load, with failures occurring in the parent laminate rather than at the weld interface. These findings suggest that the integrity of the welded joint is sufficient, and not the primary limiting factor in overall structural performance.

Environmental testing and in-space relevance

Following the completion of the TDEA project in January 2025, NASA transitioned its collaborative efforts with Agile Ultrasonics to a new initiative titled “Structural Materials Joining in Space,” which receives partial funding from the Ohio Federal Research Network (OFRN). This initiative continues the focus on generating baseline weld data under controlled thermal-vacuum conditions, with future plans to integrate microgravity scenarios, potentially through parabolic flight tests or experiments conducted in orbit.

As part of this new program, Agile Ultrasonics has engineered a custom vacuum chamber designed to emulate the in-space temperature range of -190°C to +120°C, reflecting the thermal conditions encountered on the lunar surface. This chamber is capable of operating in both ambient and vacuum conditions and features integrated sensor arrays for real-time monitoring and control of in-weld temperatures.

“The thermal dynamics on the lunar surface present significant challenges, particularly due to the potential for rapid temperature fluctuations,” says Bergan. “Our analysis indicates that if welding operations can be strategically scheduled within a 3-week window in the year, the operational temperature may hover around -80°C as opposed to the more extreme cold associated with other times. This insight allows for the development of more advantageous welding strategies for construction activities.”

Future research and development

Despite achieving promising outcomes, several critical challenges persist in the field. A primary technical hurdle is the precise measurement of temperature at the bondline during the welding process. Glenn Research Center’s Miller emphasizes that advancements in temperature measurement techniques could represent a substantial leap forward in ultrasonic welding and welding technologies at large. Currently, existing methods typically depend on indirect measurements to assess when temperatures surpass optimal processing thresholds.

Additionally, the evaluation of bond quality through nondestructive testing remains problematic. While techniques such as X-ray computed tomography and ultrasonic scanning are effective at identifying voids and delamination, they often fall short in accurately predicting bond strength. Researchers have encountered cases where interfaces that appeared well-bonded in imaging showed unexpectedly low mechanical strength, commonly referred to as “kissing bonds.” This highlights the need for the development of more reliable defect detection methodologies.

Agile Ultrasonics aims to enhance its technology readiness level (TRL) from the current TRL 4 to TRL 6 or higher. This will be achieved through ongoing in-house development, collaborative efforts with NASA and the OFRN, rigorous validation testing and system integration initiatives. Key focal points for this development include the implementation of novel temperature measurement, closed-loop control, automated process monitoring and thermal compensation algorithms, which are essential for deployment in flight-critical or automated manufacturing environments.

Collaborative efforts between NASA and Agile Ultrasonics have demonstrated the significant potential of ultrasonic welding for TPC in-space applications, especially where portability and minimal auxiliary equipment provide notable advantages. Although challenges remain, this work not only bolsters capabilities for space exploration but also enriches the broader understanding of TPC joining technologies, with promising implications for other applications in advanced structures both in space and on Earth.

Related Content

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MoreFraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreTAVieDA project team cuts aircraft door production time using thermoplastic composites, welding

Fraunhofer groups, Trelleborg and Airbus develop modular, fully automated assembly system concept to replace metals and time-consuming assembly that shows potential for scalability.

Read MoreRead Next

CIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

Read MoreIn-space 3D printing research paves way for future in-orbit fabricators

University of Glasgow researchers have demonstrated a patented process that can effectively 3D print in low-Earth gravity with feedstock and fiber reinforcement, freeing up the ability to build structures on-demand in space.

Read MoreAdvancing thermoplastic composite primary structure and morphing wings

The HERWINGT project in Clean Aviation seeks to ready technologies — including at least 16 composite demonstrators — for a hybrid-electric regional aircraft with 50% less fuel burn to be launched by 2035.

Read More