PAEK

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Ginger Gardiner

Senior Technical Editor, ÂÌñÏ×ÆÞ

Teijin Carbon, A&P Bimax TPUD braided fabric meets scalable composites manufacturing goals

A combination of Teijin Carbon’s UD thermoplastic tapes and A&P Technology’s braided fabrics translates into a PAEK biaxial fabric with minimal crimp, high drapability and other rate-enabling qualities.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreAGY, A+ Composites launch fiberglass thermoplastic tape line

Unidirectional S2 glass fiber reinforced with LM-PAEK and PEI boosts mechanical and thermal and sustainability properties for wrapped and layered composite applications.

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

Ginger Gardiner

Senior Technical Editor, ÂÌñÏ×ÆÞ

Tri-Mack introduces thin, lightweight thermoplastic composite enclosures

Durable, low-cost manufacturing support wide range of industrial uses, with option for embedded EMI shielding.

Read MoreElectroimpact, Toray, Janicki advance technologies for rapid, large-scale thermoplastic parts manufacture

Project combines Electroimpact high-speed AFP equipment, Janicki’s OOA heated layup tooling system and Toray Cetex TC1225 low melt PAEK UD tape for deposition rates of up to 4,000 inches/minute.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

Read MoreCAMX 2021 exhibit preview: Boston Materials

Supercomp, ZRT and Bimetal are three of Boston Material’s z-axis carbon fiber products developed via its patented magnetic alignment process.

Read MoreCAMX 2021 exhibit preview: A&P Technology

A&P Technology’s new product offerings include slit tape thermoplastic fabrics that can be braided into fabrics up to 60 inches wide.

Read MoreVictrex launches LMPAEK polymer grade for 3D printing

Victrex AM 200 improve melt extrusion by filament fusion (FF), direct granule extrusion, and laser sintering processes and enhances z-strength and interlaminar strength.

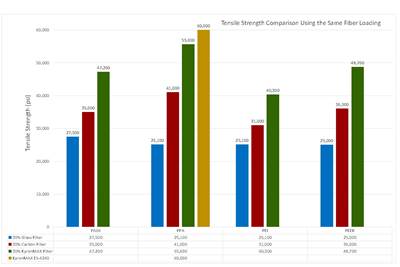

Read MoreShort carbon fiber compounds expand reach of thermoplastic composites

With fiber weight fractions of up to 50% and an array of thermoplastic matrices available, injection molding compounds are expanding composites’ capabilities.

Peggy Malnati

MMT, Contributing Writer, MoldMaking Technology

Teijin Carbon Europe launches carbon fiber/PPS UD tape

The new Tenax prepregged tape with PPS matrix allows entry into new cost-sensitive markets while offering the typical TPUD advantages like resistance to chemicals and solvents, low flammability, storage or shipping at room temperature and recyclability.

Read MoreWing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

Read MoreENLIGHTEN program launched to speed thermoplastic composites industrialization

Multi-scale modeling, testing, sensors and machine learning will advance understanding and algorithms to achieve process control and optimization for both aerospace and automotive supply chains.

Read MoreVictrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

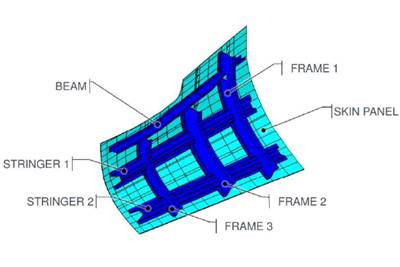

Read MoreManufacturing the upper half of the Multifunctional Fuselage Demonstrator (MFFD)

Proving industrial reliability for low-cost thermoplastic composites production using AFP in-situ consolidation, as well as continuous ultrasonic and resistance welding.

Read MoreMoving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

Read MoreClean Sky 2 FRAMES project advances heating simulation of thermoplastic composite AFP with xenon flashlamp

Heraeus Noblelight and Compositadour develop heating simulation to optimize process temperatures during automated fiber placement of composite aerostructures.

Ginger Gardiner

Senior Technical Editor, ÂÌñÏ×ÆÞ

Victrex, Daher, attain next-gen thermoplastic aircraft panel milestone

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

Read More3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreElectroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

Read MoreSurface treatment for adhesive bonding: Thermoset vs. thermoplastic composites

According to BTG Labs, common surface treatment methods like abrasion and plasma treatment work best for different materials.

Read MoreCETMA: composites R&D and innovation in Italy

From design and simulation to inline inspection, induction welding, continuous compression molding and recycled carbon fiber, this lab to support industry is advancing composites in aerospace, automotive, construction and more.

Read MoreNIAR's NCAMP announces release of first thermoplastic material

Toray’s Cetex TC1225 is a low-melt PAEK and is part of a broad effort by the National Center for Advanced Materials Performance (NCAMP) to qualify thermoplastic materials

Read More