Thermoplastics

Thermoplastics play a pivotal role in composite materials by serving as the matrix phase that binds reinforcements together. Unlike thermoset resins, thermoplastics possess the ability to soften and reform when heated, allowing for reshaping and recycling. They offer unique advantages such as high toughness, chemical resistance, and easy processing, making them versatile in various industries like aerospace, automotive, and consumer goods. Composites using thermoplastic matrices exhibit exceptional damage tolerance and are sought after for their potential in complex manufacturing processes like injection molding, enabling efficient production of intricate and high-performance parts.

Latest Thermoplastics Articles

VIEW ALLFour Syensqo innovations are recognized at 2025 SPE Automotive Awards

Syensqo’s fiber-reinforced polymers, specialty compounds and bio-based PPA materials earn automotive impact distinction.

Read MoreBelgium-Netherlands event brings together industry leader insight on TPC, FRP recycling

Save the date for this free cross-border, expert-driven event by Agoria, Sirris and Brightland Materials Center on Nov. 12 in Belgium.

Read MoreFiberglass-reinforced nylon PA12 is co-developed by AGY, Orion Compounding

Implementation of AGY’s S2 Glass fiber enhances the material’s tensile and impact strength, elongation at break, and improves tensile and flexural modulus.

Read MoreAvient, ReForm Composites accelerate TPC adoption in construction

ReForm’s pultrusion technology with Avient’s composite materials enables curved continuous fiber TPC profiles demonstrated in the PolyDowel infrastructure project.

Read MoreIRT Jules Verne, partners launch SCRATCH TPC assembly project

A continuation of SPECTRA, this project’s technological building blocks will contribute to the deployment of a matured conduction welding solution to improve aerospace-grade TPC assembly.

Read MoreAvient, FSJ Tactical advance ballistic-rated composite wall panels

Fiberglass-reinforced ThermoBallistic panels for facility protection applications are capable of encapsulating projectiles and preventing harmful deflection and ricochet.

Read MoreKnowledge Centers

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORE

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Thermoplastics News And Updates

Altair 2025 Enlighten Award winners, runner-ups push automotive boundaries

Hemp nylon-reinforced PA6 automotive exteriors, TPC acoustic elements, glass fiber stator cooling design and other innovations are recognized for their sustainability focus, holistic capabilities and lightweight designs.

Read MoreXenia presents range of impact-modified thermoplastic composites

ST Upgrade enhances the impact resistance of Xenia’s fiber-reinforced materials by 60%, a 40% increase elongation at break and can be applied across a range of formulations.

Read MoreMaruHachi Corp. to develop CFRTP cryogenic rocket fuel tank

MaruHachi is selected by the Japanese government’s Space Strategic Fund, commencing joint development with University of Tokyo and Kanazawa Institute of Technology/ICC.

Read MoreSABIC composite hybrid battery cover enhances EV safety, efficiency

SABIC collaborated with Engel, Siebenwurst, Forward Engineering, Ensinger and Envalior to develop a thermoplastic composite EV battery cover, combining strong structural performance, flame retardancy and design efficiency.

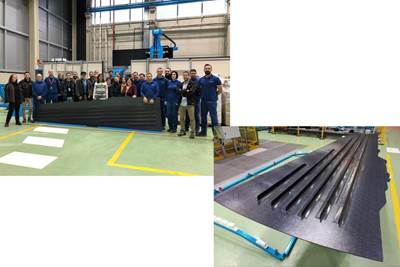

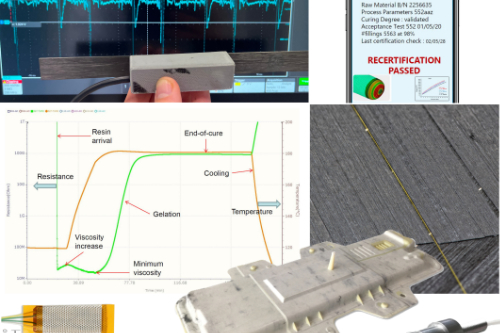

Read MoreDaher ODDICEA 2 project gains support to boost decarbonization of TPC production activities

Renewed financial support from France’s Pays de la Loire region will build on technological Industry 4.0 advances made in the project’s first phase for Daher’s Nantes facility, which has already delivered tangible results.

Read MoreCygnet Texkimp relaunches customer slitting trials at UK Innovation Centre

A production-scale prepreg tape slitting system featuring SAHM winding technology is available for thermoset, thermoplastic and ceramic tape trialing following an Asia contract win.

Read MoreFeatured Posts

Troubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MoreParis Air Show highlights advanced materials, industry momentum

This year’s international air show offered a glimpse of the rapidly expanding future for composites in aerospace.

Read MoreComposites in India: A market forecast for 2025-2030

India is the world’s fastest-growing market for composites, with a comprehensive ecosystem pivoting toward self-sufficiency in production and 200% growth in its carbon fiber value chain.

Read MorePost Cure: Bionic fiber placement produces load-optimized, nature-inspired thermoplastic composite preforms

Fibionic’s fibionic fiber placement (FPP) technology enables the development of “fiber skeletons,” semi-finished parts suitable for any application that incorporates composite reinforcement exactly where it is needed.

Read MoreScaling up thermoplastic composites recycling

Thermoplastic composites are always said to be “recyclable.” Netherlands-based recycler Spiral RTC discusses the process, challenges, applications and opportunities to building a real recycling ecosystem.

Read MoreAdvancing thermoplastic composite primary structure and morphing wings

The HERWINGT project in Clean Aviation seeks to ready technologies — including at least 16 composite demonstrators — for a hybrid-electric regional aircraft with 50% less fuel burn to be launched by 2035.

Watch