Natural Fibers for Composites

Natural fibers are gaining prominence as eco-friendly alternatives for reinforcing composite materials, offering renewable and biodegradable options. Derived from sources like jute, hemp, flax, and bamboo, these fibers are appreciated for their low cost, lightweight nature, and reduced environmental impact compared to traditional reinforcements. Natural fiber composites exhibit respectable strength and stiffness, often used in applications where their unique properties, such as vibration damping or acoustic insulation, are advantageous.

Latest Natural Fibers Articles

VIEW ALLŠkoda Motorsport continues to cut motorsport weight with Bcomp

The Czech brand looks to transition natural fiber technologies to production vehicle models after 316-kilogram cut in 2025 Enyaq RS Race pilot project.

Read MoreRWC composite radomes facilitate R4 Integration military search and rescue operations

Completed delivery of nine “no tooling” Ka-band and KaKu-band radomes are an extension of a previous program for a single proof-of-concept radome for C130 aircraft and similar platforms.

Read MoreEuropean Flax-Linen & Hemp expands technical capabilities with addition of Circular Structures

New member that includes Greenboats and Greenlander brands strengthens platform for advancing natural fiber composites across industries.

Read MoreAltair 2025 Enlighten Award winners, runner-ups push automotive boundaries

Hemp nylon-reinforced PA6 automotive exteriors, TPC acoustic elements, glass fiber stator cooling design and other innovations are recognized for their sustainability focus, holistic capabilities and lightweight designs.

Read MoreAluBas tapes by FibreCoat and A+ Composites combine technical functionality, visual design

Aluminum-coated basalt fiber tapes combine appearance and performance, featuring EMI shielding, thermal management, light weight and ease of integration.

Read MoreNatural fibers power Cupra’s vision for sustainable mobility

Cupra’s latest concept vehicle, Tindaya, demonstrates Bcomp ampliTex through both visible interior and semi-structural parts.

Read MoreKnowledge Centers

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

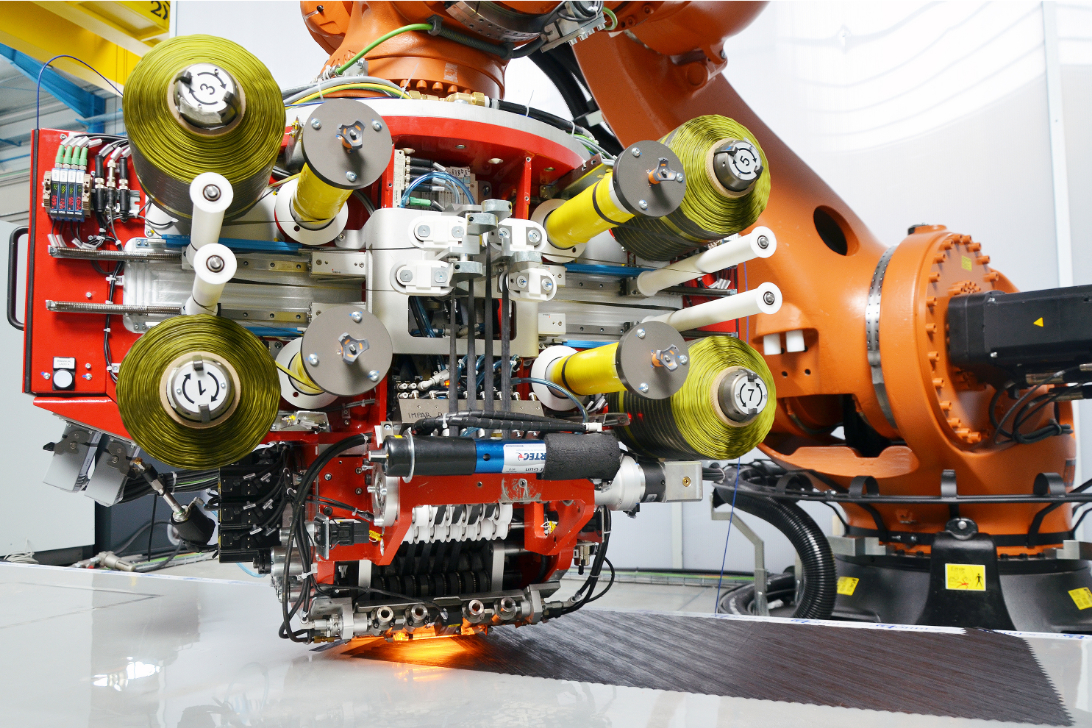

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORE

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORELatest Natural Fibers News And Updates

Startup Akvotransiro trials Wind2Water catamaran built from discarded wind turbine blades

Four-person prototype is one of many in-development hulls, floating docks and pontoons comprising bamboo composites and EOL wind blades re-engineered into reliable, environmentally conscious water vessels.

Read MorePolestar 3 sets World Record for longest electric SUV journey on single charge

Unmodified Polestar 3, which uses natural fiber composites in its interiors, achieves 935.44 kilometers on a single charge on U.K. public roads.

Read MoreBcomp natural fiber composites to enhance Sunreef catamarans

Innovative yacht manufacturer will use flax fiber-reinforced bio-based or recyclable resin to improve vibration damping, aesthetics and sustainability for its new 100 Sunreef Power cats.

Read MoreCEAD hybrid LFAM opens ways for KCL bio-based 3D printing

Partnership achieves compatibility of large-format additive manufacturing with KCL’s Formi biocomposite granules, building sustainable production options.

Read MoreSGL Carbon manufactures natural fiber prepregs for motorsports

SGL Carbon supplied prepreg materials made from Bcomp flax fiber fabric to Japanese company Tras Ltd. for the Toyota Hilux’s natural fiber body.

Read MoreORGANIC project to 3D print bio-inspired structures with bio-based materials

EU-funded Horizon Europe project tackles lower production cost, enhanced sustainability and first-time-right parts fabrication through the fusion of biology, additive manufacturing and AI.

Read MoreFeatured Posts

Spanish startup to ramp up production of “recyclable” EV prototype

Liux’s BIG electric vehicle features multiple structural components manufactured via RTM from flax fabric and a thermoset resin said to enable the entire component to be recycled and reused again.

WatchJEC World 2025 highlights: Evolving recycling and biomaterials technologies

CW technical editor Hannah Mason shares sustainability-focused composites trade show highlights featuring maturation, scale-up, new partnerships, and new technologies in biomaterials and recycling.

WatchComposites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

Read MoreBiomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreAirbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

Read More