Sheet Molding Compound

Composite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

Hannah Mason

Technical Editor, ÂÌñÏ×ÆÞ

SMCCreate 2025 event returns to Prague

Industry professionals are invited to the Nov. 4-5, 2025, event discussing developments, applications, best practices and solutions in SMC and BMC.

Read MoreFraunhofer IGCV develops helicopter door shell using SMV composite

SMC-replacement material subjected to vario-thermal pressing cycle achieved a 1.2-millimeter-thick, complex-shaped door shell, demonstrating feasibility for future aerospace components.

Read MoreSMC, compression molding capabilities to support European composites manufacturers

JEC World 2025: SFG Composites presents its ability to deliver high-quality, cost-effective composite solutions in-house with fast lead times as an alternative to domestic and Asian suppliers.

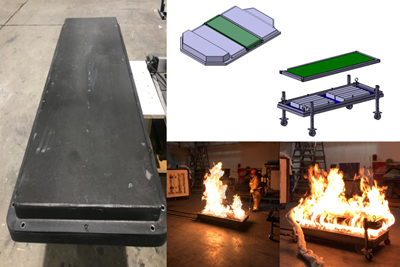

Read MoreAOC resins support SMC composite doors for air raid shelters

The recent use case exemplifies the application of AOC’s SMC resins in related fields, thanks to their strength, resistance and longer lifespan in comparison to metal or fiber-reinforced concrete options.

Read MoreDieffenbacher acquires Schmidt & Heinzmann composites business

The acquisition, which includes all intangible assets of the business unit, will expand Dieffenbacher’s SMC delivery spectrum, enable potential for portfolio growth and synergies.

Read MoreAOC introduces UV-Resistant Automotive System for SMC parts

AOC’s novel formulation, tested in the lab and in real-world environments, delivers a deep black, molded-in color that resists fading and offers high scratch resistance.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Stewart Mitchell

Contributing Writer

IDI Composites opens new global headquarters, manufacturing and technology center

The Noblesville, Indiana, facility includes SMC and BMC manufacturing, an R&D center and the company’s corporate headquarters.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreJohns Manville launches multi-end roving MultiStar 272

Multi-end fiberglass roving serves as a reliable product for SMC compounders aiming to excel in automotive applications.

Read MoreMatrix Composite highlights carbon fiber SMC prepreg Quantum-ESC

Prepreg produced by LyondellBasell features high flow, rapid tool loading capabilities.

Read MoreMar-Bal expands SMC expertise through AltraSet materials division

The BMC company aims to fill the SMC market gap for those seeking optimal, low-volume demand with custom formulation and high material value.

Read MoreComprehensive service formulates standard, custom SMCs

CAMX 2024: As an SMC product manufacturer, Molding Products LLC provides SMC formulations and technical support for diverse markets, from R&D to post-production.

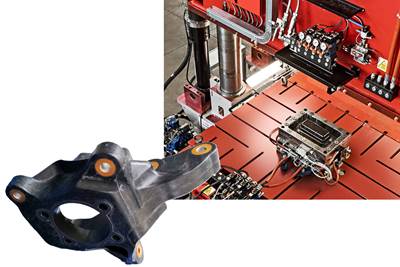

Read MoreA digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

Ply stacking, cutting process optimized via automation, smaller footprint

CAMX 2024: Schmidt & Heinzmann customers are able to produce SMC or dry fiber fabric stacks more efficiently thanks to the AutoCut Pick&Place system.

Read MoreWAG Wernli to produce composite brackets for Dufour Aero2 drone

The Swiss company was chosen for its C-SMC expertise, which will replace original aluminum brackets to enhance weight savings, corrosion resistance and adhesive bonding capabilities.

Read MoreSMC BMC Design Award 2024 winners showcase projects at JEC World

Awards ceremony to be held on March 6th will recognize the top three selected SMC and BMC designs submitted by European design students and young design professionals.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreNational Composites announces partners with compression toolmaker Laval

The new alliance will broaden National Composites’ capabilities in SMC and BMC and tooling, while providing customers with comprehensive solutions, from initial design to final delivery.

Read MoreDieffenbacher highlights Fibercut system for increased productivity

Dieffenbacher’s fully automated cutting and stacking system enables automated SMC processing applications.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Peggy Malnati

MMT, Contributing Writer, MoldMaking Technology

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreAptera joins forces with C.P.C. Group to accelerate solar EV production

Specialized composite bodies are being produced in Modena, Italy, for Aptera’s BinC vehicle, enabling eventual manufacturing ramp-up of 40 vehicles/day to meet demand targets.

Read MoreSMC simulation tool enhances design optimization

CAMX 2023: FiRMA, Engenuity’s new approach to SMC, uses a predictive technique that accurately reflects material properties and determine the performance range an SMC part or structure will exhibit.

Read MoreGraphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read More