Space

Composites have been used in space since our early steps into the cosmos. Often turned to for their light weight and high strength, these materials have a history of use in spaceflight in such applications as payload fairings, satellite structures and heat shields. â–º Explore the technologies, materials and strategies used by composites manufacturers working in the evolving space market at our virtual CW Tech Days: New Space Applications. Learn more and register here!

ESSENTIAL READING

VIEW ALLComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreMaterials & Processes: Composites fibers and resins

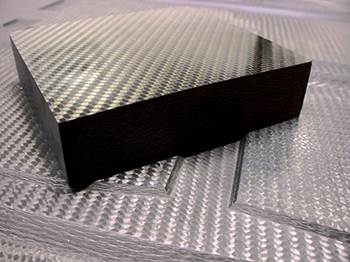

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Introduction

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. This article outlines the case for composites and introduces SourceBook's overview of the materials and processes used to make them.

Read MoreKnowledge Centers

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORE

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORELatest Space News And Updates

Rocket Lab opens Launch Complex 3 for Neutron rocket debut

Fourth launch site constructed in under two years will be exclusively used for Rocket Lab’s upcoming medium-lift composite rocket Neutron.

Read MoreBlueshift launches AeroZero ultra-low outgassing thermal protection tapes

Thin and flexible thermal tapes mitigate extreme thermal cycling in orbital and high-vacuum environments and meet the ASTM E595 outgassing standard, excelling in spacecraft and LEO satellite designs.

Read MoreSmartbeam develops HMS-embedded composite profiles for space

Project goals adapted filament winding to properly integrate optical and carbon fiber sensors and meet technical requirements, resulting in a verified, simplified process for smart composite structures at reduced cost.

Read MoreEurope launches MetOp-SG A1 meteorological satellite

Airbus-built satellite, supported by Beyond Gravity composite materials, is the first in a series of six satellites that will support weather forecasting into the mid-2040s.

Read MoreRWC completes prototype radome using Renegade NCAMP-certified composite

Completed prototype for Georgian Aerospace uses a low-dielectric epoxy prepreg on quartz fabric, which has passed radio frequency testing with results equivalent to traditionally higher-cost, low-dielectric matrix options.

Read MoreCRP USA highlights 3D printing composites success for small, flight-ready satellite missions

A combination of the Windform portfolio of CFRTP and GFRTP materials and SLS printing have proven CRP’s ability to meet critical space requirements.

Read MoreFeatured Posts

National Composites Week 2025: Space

Commemorating the theme “Performance With Purpose,” CW has gathered key stories over the last year that exemplify how composites have progressed space exploration and satellite programs.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreRevolutionizing space composites: A new era of satellite materials

A new approach for high volumes of small satellite structures uses low-CTE, low-cost CFRP cellular core, robust single-ply skins and modular panel systems to cut lead time, labor and cost for reflectors, solar arrays and more.

Read MoreParis Air Show highlights advanced materials, industry momentum

This year’s international air show offered a glimpse of the rapidly expanding future for composites in aerospace.

Read MoreAutomating oxide CMC for higher part volumes

FOX Composites has adapted infusion and RTM for slurry-based matrices, commercializing its VASI and IFOX technologies for automatable, scalable, serial production of high-quality oxide ceramic matrix composite parts, already proven in flight missions and a pilot-scale line.

Read MoreOptimizing a CFRP landing leg demonstrator

MT Aerospace achieves design for manufacturing, integrating multiple elements into one-piece structure using AFP and 3D printed tooling to meet time and budget constraints.

Watch