Bonding of Composites

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

Latest Bonding Articles

VIEW ALLMaster Bond features non-drop cryogenic epoxy

EP29LPSPND-3 is a two-component, electrically and thermally insulating epoxy compound with a paste consistency that can be used for bonding and sealing applications.

Read MorePlasma-enabled bonding engineered for composites, metal surface prep

CAMX 2025: Plasmatreat presents plasma breakthroughs for aerospace bonding and corrosion prevention through live demos, technical sessions and presentations, surface consulting and more.

Read MoreControlled polymer ablation enables stronger composite bonds

CAMX 2025: Plasma Bound’s surface pretreatment technology using CPA cleanly and effectively energizes similar and dissimilar surfaces to enhance bonding and joining.

Read MorePlasmatreat Technology Days 2025 celebrates 30 years of Openair-Plasma

More than 200 guests accepted the Steinhagen-based family business’ invitation to discuss new applications of atmospheric plasma systems in surface pretreatment.

Read MoreEco-friendly precision tooling offers flexibility, consistency

CAMX 2025: For more than 50 years, Coastal Enterprises has supported design, prototyping and composite layup applications with its Precision Board urethane tooling board and custom bonding offerings.

Read MoreHenkel, Synthomer partner to cut carbon emissions in adhesives

Integration of Synthomer Clima resins into Henkel Technomelt hot-melt adhesive portfolio targets significant Scope 3 GHG emissions reductions for electronics, automotive, comsumer and composites customers.

Read MoreKnowledge Centers

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORE

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORELatest Bonding News And Updates

IPS Adhesives debuts Scigrip SG2000 adhesive in North America

The adhesive’s 1:1 mix ratio and long open time provides transportation, construction and marine industries with much-needed routine simplification and flexibility.

Read MoreCW finalizes Tech Days: Bonding and Welding agenda

A total of six presentations — four welding and two bonding — presented by industry experts will explore the drawbacks, potential and evolving technologies available to bonding and welding methods.

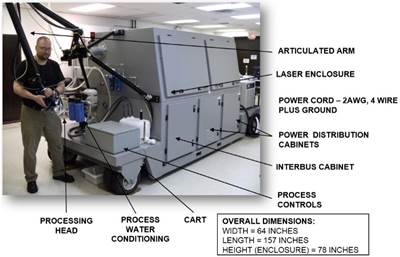

Read MoreUDRI opens RAAM lab to advance robotic femtosecond laser

RoboCLASP, an athermal ablation system initiated for preparing composites for bonded assembly, is being roboticized to advance U.S. Air Force needs.

WatchAnalySwift receives NASA STTR contract to enable second-use spacecraft infrastructure

Together with Purdue, AnalySwift aims to develop a composite heater layer and a novel software tool or module to achieve assembly, disassembly of thermoplastic composite joints in space during long-duration missions.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreControlled polymer ablation technology seeks to redefine surface prep

CAMX 2024: Plasma Bound’s CPA technology, powered by quality control system Vulcan, applies atmospheric pressure plasma to achieve high-level composite bonding.

Read MoreFeatured Posts

Understanding the difference between bonding and welding

Composites bonding and welding are two similar but distinct processes that overcome challenges related to fasteners or drilling. Here are some resources to get you started.

Read MoreVIDEO: Plasma surface treatment technology improves adhesion

Plasmatreat demonstrates its Openair-Plasma surface treatment technology, which can enhance material adhesion.

WatchDetermining steel/composite failure load of bonded repair assemblies

Bureau Veritas and partners use a novel equivalent interface test specimen and simulation to predict failure load in bonded composite patch repairs to steel structures.

Read MoreJEC World 2023 highlights: Recycling, biocomposites, smaller equipment and expanding brands

CW senior technical editor Ginger Gardiner addresses some of this year’s hot topics, ranging from novel biocomposites and recycling technology solutions from myriad startups to upgraded, but equally sustainable, equipment from well-established companies.

WatchFrom plant tours to EV battery enclosures: The top 10 ÂÌñÏ×ÆÞ articles of 2022

Through a variety of editorial content, CW explored the trends and topics that are rapidly flourishing in the industry. Based on Google Analytics, these top 10 articles were considered the most popular.

Read MoreLaser bondline inspection becomes reality

One of the Holy Grails of composites manufacturing has been reliable verification of adhesive bondline strength integrity. A technology that does just that has arrived.

Read More