Design & Tooling for Composites

Narrow Your Design & Tooling Search

Latest Design & Tooling Articles

VIEW ALLPurdue, AnalySwift launch CompositesAI platform to democratize air mobility structure design

CompositesAI integrates with AnalySwift’s VABS and SwiftComp software to streamline the design, simulation and performance evaluation of composite structures — especially rotor blades, shells and panels.

Read MoreSiemens, Ducati extend partnership to advance innovation

Siemens Xcelerator Platform helps extend racing innovation to production bikes, reduces time for complex composite parts and enables remote design/3D printing at track, digital twin and faster development.

WatchSiemens adds AI to Simcenter Testlab, reinventing modal testing and analysis

Simcenter Testlab, already used with composites, now uses intelligent test automation and AI assistance to execute physical testing workflows faster, smarter and earlier in structural design programs.

Read MorePutting next-generation composite materials, processes to the test

Research at Faserinstitut Bremen’s ECOMAT site, alongside industry partners, aims to enable sustainable, aerospace-focused composites — including thermoplastic welding and cryogenic material testing.

Read MoreAddcomposites releases free professional composites design software suite

Browser-based tools eliminate $320,000 annual licensing barriers, making advanced composite engineering accessible to 50,000-plus engineers and educational institutions worldwide.

Read MoreAcquisition joins MPM Group and Lamplas GFRP, composite molding expertise

MPM Group’s strategic alignment of the two businesses will build enhanced capability, technical expertise and broader market reach in the U.K.

Read MoreKnowledge Centers

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORE

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Design & Tooling News And Updates

Instron introduces table model version of 100 kN testing system

Engineering advancement eliminates space and power constraints, common obstacles in the lab, while handling low- and high-force application testing for high-strength metals, alloys and composites.

Read MoreOtto Aerospace develops AI model for Phantom 3500 business jet aerodynamics

Tailored AI model will enable detailed aerodynamic analysis of current and future Otto aircraft configurations, streamlining design speed, precision and informing the aircraft program’s composite structures.

Read MoreDFS Composites acquires Mexico wind blade tooling facility, expands North American operations

With a new 300,000-square-foot site in Ciudad Juárez, DFS Composites boosts its global footprint and ability to supply composite tooling for wind energy across the Americas.

Read MorePlyable secures Automated Molding feature patent

First EU and U.K. patent builds in a new level of protection for customers using the company’s AI-powered mold design software.

Read MoreTechmer PM HiFill GF-PET material system bridges low, high-temp tooling gap

GF-PET compound delivers dimensional accuracy, thermal stability and accessible shape compensation data for high-performance 3D printed tooling applications.

Read MoreScalable automation technologies drive composites efficiency, consistency

CAMX 2025: Learn how Magnum Venus Products’ equipment portfolio is evolving, with a focus on MVP Motion line, INV3, IPD, Nitrotherm spray and Flex Molding technologies.

Read MoreFeatured Posts

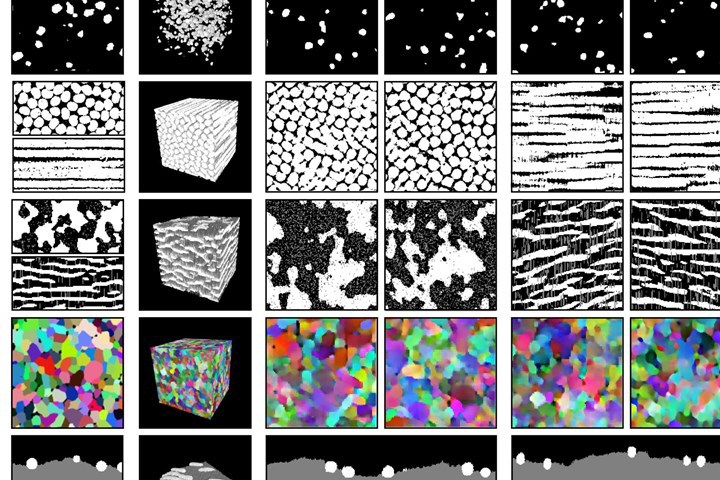

Modular approach to material card development of composites

Forward Engineering GmbH walks through a modular testing and simulation approach for automotive/aviation composites enabling more accurate material selection earlier in the design phase.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

WatchTroubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreMechanical testing of ceramic matrix composites

Today’s CMC materials, robust and resistant to high temperatures, provide their own set of challenges when determining their performance through mechanical testing.

Read MoreUsing multidisciplinary simulation, real-time process monitoring to improve composite pressure vessels

Multi-pronged approach closes the loop between design and production of Type 3, 4 and 5 pressure vessels, enabling simulation of as-built composite tanks to improve performance and storage capacity while reducing weight and cost.

Watch