Source (All Images) | MORPHO project

(Manufacturing, Overhaul, Repair for Prognosis Health Overreach) was a Horizon 2020 funded research project (September 2021 – January 2025) that aimed to optimize the manufacturing and life cycle management of carbon fiber-reinforced polymer (CFRP) aeroengine fan blades. It would thus extend European industrial leadership by advancing cost-effective, flexible and ecological manufacturing, maintenance and recycling processes for the next generation of multifunctional composite airframe parts.

Consortium and objectives

The MORPHO consortium comprised 10 partners from six countries. Led by the (ENSAM, Paris, France) it included aeroengine manufacturer (Paris, France), Fraunhofer IFAM (Bremen, Germany), (TU Delft, Netherlands) and the (Patras, Greece), as well as sensor suppliers Synthesites (Piraeus, Greece), (Châtelet, Belgium) and (Braunschweig, Germany) as well as Spanish partners , responsible for communications and dissemination, and simulation software supplier .

“The goal was to define an industrial process for producing a multifunctional (or “smart”) composite fan blade, which is also multi-material, because the leading edge is titanium,” explains Nazih Mechbal, director of the 180-person (PIMM) laboratory at ENSAM. “We wanted to give it cognitive function, from its manufacture to end of life [EOL], by embedding sensors and enabling life cycle management through data-driven hybrid twins and machine learning [ML] algorithms. We also wanted to develop a disassembly process that could be industrialized for separating and recycling the titanium leading edge and composite structure.”

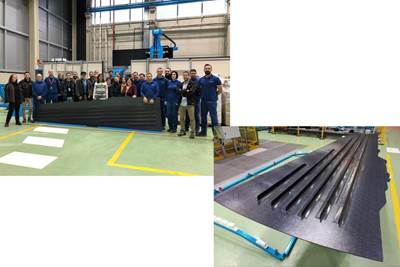

The MORPHO demonstrator was a foreign object damage (FOD) panel representing a section of a LEAP engine fan blade.

To demonstrate this, the MORPHO consortium developed a foreign object damage (FOD) panel, “representing a fan blade for the LEAP engine,” says Mechbal, “and used by Safran to test all this capability.” The project succeeded in multiple achievements including:

- Optimized RTM process with 20% shorter cure cycle using advanced dielectric sensors and real-time data analytics for monitoring viscosity, Tg and cure.

- Hybrid twin of RTM process predicted resin flow and cure with <1% error in under 1 millisecond; combining high-fidelity physics-based simulations with real-time process data enabled identifying local permeabilities in woven preforms which significantly enhanced quality control during production.

- Novel AI-based structural prognostics and health monitoring (SHPM) system for aeroengine fan blades that integrates low-frequency fatigue testing, advanced sensing techniques and deep learning architectures to predict stiffness degradation and remaining useful life (RUL) based on strain and other measurements.

- Demonstrated laser shock disassembly of CFRP blade from titanium leading edge, with process parameters tuned using simulation to ensure no damage to composite materials for recycling/reuse.

Hybrid twins for RTM

The MORPHO project’s hybrid twin (top) started with a multiphysics, digital model/virtual twin (bottom). Source | ENSAM

“A digital twin is when you use digital models to create a replica of your system using simulation,” says Mechbal. “In a hybrid twin, we enable dialog between this digital data and physical data obtained from sensors. To do this, we first build the physics-based RTM process simulation and finite element [FE] simulation, and then add data-driven online learning to create a hybrid twin.”

Virtual twin. The virtual twin of the RTM process is a digital twin developed as a multiphysics model comprising multiple steps:

- Resin injection (Newtonian fluid flow into 3D woven fabric, Darcy’s law, potential to form racetracks or dry spots)

- Curing (kinetics of polymerization, Kamal-Souror model)

- Heating/cooling (conduction + convection, thermo-dependent mechanical properties).

“From this complete physical model, which requires time and computing power, we extract a reduced model using proper general decomposition [PGD] or any other physics-informed reduction method,” says Mechbal. “Although these reduced models are quick and can be run on the fly during the RTM process, there will be discrepancies with the physical data. This is where we use AI and use it only to estimate these discrepancies. Thus, we retain as much physical knowledge as possible and only use ‘blind’ methods for discrepancies that may arise from the model reduction and unmodeled phenomena such as noise, environmental conditions, etc.”

Physical layout of Synthesites dielectric sensors and data acquisition units in the MORPHO project’s FOD panel demonstrator. Source | Synthesites

Physical measurements. For this second part of the hybrid twin, MORPHO used two kinds of sensors during the RTM process. Dielectric analysis (DEA) sensors from Synthesites were used for process monitoring and measuring the resin flow front. The image at left describes the equipment setup.

As I explained in my 2020 blog on Synthesites, DEA has been used for decades. For MORPHO, Synthesites supplied durable in-mold sensors and in-line sensors at the inlet and outlet gates which fed data into Optiflow and Optimold data acquisition units. Optiflow units monitor resin arrival and temperature and can identify production deviations during resin infiltration. Optimold units use temperature and resin resistance measurements to make calculations and monitor the state of the resin including mix ratio, chemical aging, viscosity, Tg and degree of cure. The data is then analyzed and results are displayed on a laptop using Synthesites’ ORS software.

The Cure Simulator uses a thermocouple in the RTM part to copy the cure process on a resin/prepreg sample and determine the cure level of the part, eliminating unnecessary cycle time and energy. Source | Synthesites

In addition, this setup used an additional piece of equipment, the . As explained in my 2022 blog on the SuCoHS project, using only one thermocouple, the Cure Simulator can copy the cure process taking place inside the RTM mold (or in that case, the autoclave) and determine the cure level of the composite to identify the point at which it is cured. As explained by Wilco Gerrits, senior R&D engineer and SuCoHS program manager at Royal Netherlands Aerospace Centre (NLR, Marknesse), “this enables ending your autoclave process when it meets your cure requirements instead of keeping it at temperature for an extra half an hour just to be on the safe side.”

“But we also looked at a process to put fiber optics with FBG [fiber Bragg grating] sensors from FiSens inside the 3D woven composite preform,” says Mechbal. “We did this using a manual method as proof of concept and also used a more automated weaving process. Because it’s a 3D preform, we are just weaving another fiber there. We did a lot of tests in the 3D woven preform and there was no noticeable impact from integrating the FBG sensors.”

Fiber optics with fiber Bragg grating (FBG) sensors were integrated into the FOD panel. Source | FiSens

RTM trials

Using a steel matched mold set designed by Safran, MORPHO completed multiple RTM trials to develop a sensor and hybrid twin approach that was reproducible and robust. “For example, we used the virtual twin to predict in real time physical parameters like resin permeability of the preform,” Mechbal explains. “We also had the input coming from the DEA and FBG sensors, which gave us the actual resin flow that we could compare in real time to what we simulated. And due to the layout of our sensors, this included a display of how the permeability changed by zone.”

During RTM trials, the MORPHO project demonstrated the ability to monitor resin injection, filling of the preform and cure. Source | ENSAM

A specific data acquisition interface was developed in MATLAB to gather data from all sensors (fiber optic/FBG, resin arrival, flow rate, pressure and temperature). This interface, also connected to the hybrid twin, can predict — in real time — flow front position and local material properties, says Mechbal. It also enables real-time dialogue between the RTM trial and the hybrid twin, handling both reduced models and data from experimental measurements simultaneously thanks to parallel processing. It can also be used offline to load both reduced models and sensor/process data measurements during RTM for further analysis, and is able to read HDF5 files as well as all raw source files.

The vision, he adds, is to keep advancing this technology so that the RTM process can be adapted as needed in situ

----- SLIDE SHOW -------------

SHM using printed PZT sensors

The original vision of the MORPHO project was always to use sensors, not only to enable a more efficient manufacturing process, but to also impart cognitive function while the part is in service, including structural health monitoring (SHM) and prognostic capability for maintenance. “The sensors we used to optimize the RTM process will also be used for SHM to detect impacts, etc.,” says Mechbal. “But for this, we added other types of sensors, including piezoelectric [PZT] sensors, which were printed on the surface of FOD panels.”

Although FBG for SHM has reached TRL 8-9 in the aerospace industry, Mechbal’s expertise is in PZT technology. Thus, his team at ENSAM worked with MORPHO partner Fraunhofer IFAM to advance PZT sensors for SHM. “While we knew that FBG sensors would give a lot of information on strains and could be used to predict the remaining life of the structure,” he explains, “we saw an ability for PZT sensors to complement this.”

Printing of piezoelectric sensors onto FOD panel. Source | ENSAM, Fraunhofer IFAM

Printing PZTs. Screen printing with silver conductive paste and piezoelectric lacquer on FOD panels was used to create three-layer sensors comprising a top electrode, a 135-micrometer-thick piezoelectric layer and a bottom electrode. “After printing, the part goes into an oven to achieve polarization,” says Mechbal. This induces the piezoelectric effect, enabling the sensors to convert mechanical stress into electrical signals and vice versa. For MORPHO, the printed sensors were processed at 100°C for 30 minutes. “This is a process that could easily be industrialized for composite fan blades,” he adds. “We can also print the wires on the part, but for MORPHO, we didn’t want to have a lot of variables, so we just used regular wire and connectors, to reduce complexity.”

PZT sensor testing

Multiple tests were performed on FOD panels with printed PZT sensors on the surface, including:

- Electromechanical impedance to detect impact events and determine their location and impact energy.

- Acoustic emission as a passive method for monitoring the damage process.

- Lamb wave interrogation for active monitoring of damage onset and evolution.

Testing to detect impact event damage, location and energy levels. Note the estimated impact location from the sensors was indeed the actual location. Source | ENSAM, Fraunhofer IFAM

“Using FOD panels with a titanium and aluminum leading edge, we proved that we can detect damage from impact with a hammer,” explains Mechbal, “including the position and level of energy. And this can be done automatically, because the PZT sensors are a passive approach. In this case, we didn’t send waves but just listened and applied algorithms based on correlation with parameters such as time of flight. These then gave the position and level of impact energy that the FOD panel was subjected to.”

Testing at TU Delft used both PZT and FBG sensors in impact and fatigue (top) as well as investigations with lamb waves (bottom). Source | ENSAM, TU Delft

Test panels were also subjected to fatigue testing, performed by TU Delft. “These panels were equipped with PZT and FBG sensors,” notes Mechbal. “We used a hydraulic machine to perform calibrated impact and then recorded this with a camera as well as collecting the sensor data. We also tested to see if we could use these sensors to send and receive lamb waves.” These have been proven effective for detection and quantification of damage in composite laminates.

The image above shows measurements that proved the printed PZT sensors can both correctly emit and sense lamb waves.

“We then tested some probabilistic approaches for damage detection,” says Mechbal. “We started with a pristine panel, created impact damage and then looked to see if there is a difference in the measurements between them. We were checking to see if the structure was okay or not. The green diamond is where we estimated to have the location of damage with the yellow field of probability around it. And the cross in black is the actual damage that we detected with the sensors. These were good results for this kind of system, which wasn’t optimized in terms of sensor placement.”

Test data for undamaged panel in green on graph with damaged panel in red, and at right, estimated damage location at the green diamond with actual impact at the black cross. Source | ENSAM, TU Delft

“We have developed a good database of how these sensors perform with various damage detection methods that we’re now trying to share with the community,” he notes. “This technology of using printed PZT sensors for SHM is a new paradigm for SHM, enabling a more automated approach as we can print the sensors as quickly as we want and also the wires. Not only can this single sensor type handle several functionalities, but it’s fast and affordable to place as many sensors as we want, so that even if we have a part where some sensors are damaged and lost, we have enough redundancy to always detect and locate damage.”

“… we can print the sensors as quickly as we want and also the wires … it’s fast and affordable to place as many sensors as we want, so that even if … some sensors are damaged and lost, we have enough redundancy to always detect and locate damage.”

“The printing also makes it easy to place the sensors where we can easily plug into them to interrogate the parts when the aircraft is on the ground,” says Mechbal. “For example, the plane docks at the airport, and we simply plug into it and test by sending waves and taking measurements. We can then see if there is damage, or perhaps a change of stiffness in certain areas of the fan blade, as well as the amount. We can then try to quantify the severity of the damage using algorithms.”

Disassembly and recycling

The last part of the MORPHO project dealt with disassembling of the part for recycling or reuse. “The first route we proposed for the FOD panel was to disassemble the titanium leading edge from the composite and also use the sensors that are embedded to monitor this process,” says Mechbal.

“The disassembly was done here at ENSAM using laser shock dismantling, where a high-power laser beam creates a wave that we send to a sacrificial layer on the composite side of the specimens,” he continues. In this case, the sacrificial layer was a thin aluminum tape adhesively bonded to an eight-ply-thick CFRP coupon representative of the FOD panel. “This setup was just to prove that disassembly was possible.”

Laser shock disassembly process for separating metallic leading edge from CFRP laminate. Note the system that holds the samples has an inlet that allows water to flow over the area to confine the expansion induced by the plasma. Source | COMET, ENSAM

“We exposed the samples to the laser beam, which created a small plasma wave resulting from the temperature dilatation (thermal expansion),” notes Mechbal. “The setup includes using a laser-transparent material, such as water, to confine the expansion and further increase the pressure induced by the expanding plasma. This results in the generation of a compressive shock wave in the bulk of the material that propagates inside depending on the density of the material and other parameters.”

”We proved that we can create delamination at any layer in the composite,” he continues, “and control both the location and size of the delamination by tailoring the laser parameters. We then used this process to go further than delamination and actually disassemble the titanium leading edge from FOD panels. We also tested FOD panels with an aluminum leading edge. The method is the same — it just required new calibration.”

Mechbal explains how this tuning of parameters enables dismantling the components without damaging the composite, adding that MORPHO project partner University of Patras also developed a good FE simulation that predicts how this process achieves the dismantling, including damage results.

Lab scale tests showing CFRP sample before (a) and after (b) pyrolysis, with recovered carbon fiber at right, and at bottom, micrographs showing residual resin sticking on the recovered carbon fiber after pyrolysis (left), which was then removed via oxidation (right). Source | Comet Group

After the separation, the composite was processed by Comet Group, one of the MORPHO partners in Belgium, which used a pilot production line to pyrolyze the resin and reclaim the fiber. It developed an optimal process of pyrolysis for 2 hours followed by 30 minutes of oxidation. This resulted in recycled carbon fiber (rCF) with mechanical property degradation limited to around 10%. The idea, says Mechbal, is to use this in automotive or aeronautic interior parts but not structural parts.

Challenges, achievements, possible application for open rotor engines?

Overall, the MORPHO project was successful, says Mechbal, with multiple technologies demonstrated and moved forward, although there were significant challenges. ”The RTM process was easy to monitor using sensors, but integrating the sensors into the process was difficult. Integrating FBG sensors into the process was very laborious, requiring several specific developments and tests. The same was true for developing printed PZT sensors for SHM,” he notes. “We spent a lot of time developing how to integrate FBG and PZT sensors for the SHM process.”

He also notes that for the RTM process, the sensors are being used in an open loop. “The vision was to provide a control feedback loop to optimize the process, but that is not easy to do and requires more development,” he says.

“The process of printing PZT sensors is something that really changes the paradigm for SHM … including how to optimize their placement and interrogation.”

Meanwhile, he sees the printed PZT sensors as one of the project’s largest achievements. “The process of printing PZT sensors is something that really changes the paradigm for SHM,” says Mechbal. “I have been developing this technology for 10 years, including how to optimize their placement and interrogation. Now, it’s very easy to print and use them. This is something that can be done at the end of any structure manufacturing process.”

“For recycling hybrid composite/metal parts, I think the laser dismantling process opens a lot of possibilities,” he continues. “Also, Comet has completed a business study to quantify the energy required for pyrolysis and what is possible to earn from rCF. Their analysis shows recycling using pyrolysis could be feasible for these fan blade type structures, reusing the fibers in other composites.”

Will ENSAM and other MORPHO partners continue with any of the technologies demonstrated? “This was our vision at the beginning of the project,” says Mechbal, “in alignment with Safran’s priorities at the time. We have given them the software for the hybrid twin of the RTM process and we’re now discussing how to mature the TRL further for the sensor technologies. We didn’t do any tests on an actual fan blade — only the demonstrator panels. So, it is still necessary to see what happens when you use these technologies in an actual flying part.”

“... without a nacelle, the blades are exposed and can experience a lot of FOD impacts. ... even small effects can have a large consequence during operation. For example, they can change the equilibrium of the rotation … But we have proven SHM is possible that can see these damage events and changes in structure.”

Source |

The use of these sensors to detect damage is indeed interesting because for the next-generation single-aisle aircraft, slated to enter service after 2035. “I don’t know if open rotor is the future,” says Mechbal, “but it was still a priority project for Safran at the beginning of the MORPHO project. However, open rotor designs present a challenge, because without a nacelle, the blades are exposed and can experience a lot of FOD impacts.” And such impacts can create issues for all CFRP parts.

For aeroengine fan blades, however, even small effects can have a large consequence during operation. For example, they can change the equilibrium of the rotation, which can be very serious, says Mechbal. “When there is large damage, you can see it,” he explains. “You don’t need SHM. But when you have a small impact and perhaps only barely visible damage on the outside, there could be delamination and/or change of stiffness on the inside that you cannot see. And this is something that changes the rotation of the fan blade. But we have proven SHM is possible that can see these damage events and changes in structure. I think MORPHO has advanced technologies that will create new opportunities and possibilities for composites.”

Related Content

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreRead Next

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreAdvancing thermoplastic composite primary structure and morphing wings

The HERWINGT project in Clean Aviation seeks to ready technologies — including at least 16 composite demonstrators — for a hybrid-electric regional aircraft with 50% less fuel burn to be launched by 2035.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More