Filament Winding

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Latest Filament Winding Articles

VIEW ALLHybrid system by Taniq combines filament winding, AFP

The solution combines two key composites manufacturing processes in a single system, increasing design capabilities and manufacturing efficiency.

Read MoreMarket report: Composites and carbon fiber in hydrogen storage

This first-of-its-kind technical report from ÂÌñÏ×ÆÞ breaks down the key economic and engineering variables influencing carbon fiber composite tanks for hydrogen-powered mobility.

Read MoreMFTECH makes improvements to MF3 automated filament winder

Compact robotic winder supports optimized filament winding operations and machine use with fixed material feeding for process stability.

WatchUniSQ, iLAuNCH Trailblazer program drive digital twin innovation for composite repairs

Working with Boeing Australia, Memko and Dassault Systèmes, the University of Southern Queensland (UniSQ) has developed a digital twin via the 3DEXPERIENCE platform, digitizing processes that could lead toward more efficient and effective maintenance, repair and operations of future fleets.

Read MoreCygnet Texkimp relaunches customer slitting trials at UK Innovation Centre

A production-scale prepreg tape slitting system featuring SAHM winding technology is available for thermoset, thermoplastic and ceramic tape trialing following an Asia contract win.

Read MoreSmartbeam develops HMS-embedded composite profiles for space

Project goals adapted filament winding to properly integrate optical and carbon fiber sensors and meet technical requirements, resulting in a verified, simplified process for smart composite structures at reduced cost.

Read MoreKnowledge Centers

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORE

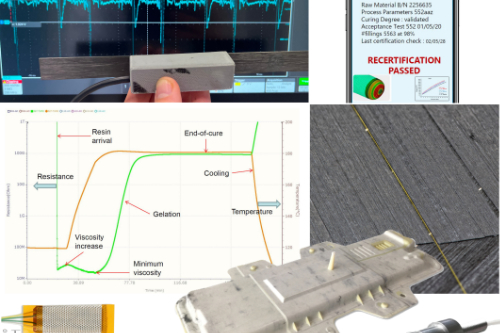

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Filament Winding News And Updates

Scalable automation technologies drive composites efficiency, consistency

CAMX 2025: Learn how Magnum Venus Products’ equipment portfolio is evolving, with a focus on MVP Motion line, INV3, IPD, Nitrotherm spray and Flex Molding technologies.

Read MoreFilament winding is backed by customized automation tech

CAMX 2025: Composites machine manufacturer Roth presents itself together with technology partner Weiss Technik, offering filament winders, specialized software concepts and customer support.

Read MoreAutomated composites processing systems facilitate customization, productivity

CAMX 2025: Mikrosam’s filament winding, prepreg slitting and rewinding, towpreg, AFP/ATL and flexible double-belt press prepreg equipment meet precision and quality demands.

Read MoreRWC delivers composite frac plugs for downhole environments

Filament-wound fiberglass/epoxy frac plug billets, developed as part of a contract with an oilfield service company, address the very demanding performance needs of oil and gas.

Read MoreExel, Flying Whales advance airship R&D collaboration

This time, Exel has signed a contract to deliver 75 kilometers of pull-wound carbon fiber tubes for the LCA60T VTOL aircraft.

Read MoreAksa Composites to advance H2 composite tank production with Mikrosam filament winder

Modularly designed system enables easy integration into existing production environments, support Aksa’s ambitious development projects.

Read MoreFeatured Posts

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreHigh-tension, vertical filament winding enables affordable flywheel energy storage system

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.

WatchPost Cure: Parallel winding technique demonstrates CFRP anisogrid design optimization

Over the years, CIRA has demonstrated its patented CFRP parallel winding technique in a variety of ways for space applications. The lattice structure for the Vega-C launcher stage is a prime example.

Read MorePlant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreBeyond filament winding: Fabricator expands into sensor technology, hydrogen tanks and more

CW Top Shops 2024 honoree B&T Composites’ story includes diversification into new markets and technologies like photonics-based structural health monitoring, aerospace and hydrogen tanks.

Watch