Additive Manufacturing/ 3D Printing Using Composites

Additive manufacturing, commonly known as 3D printing, has revolutionized composite production by enabling the layer-by-layer construction of intricate composite structures. In the realm of composites, additive manufacturing techniques allow for the creation of complex geometries with precise fiber orientations and resin distribution, optimizing material performance. This technology offers the flexibility to customize parts, reduce waste, and experiment with novel composite combinations. By depositing materials layer upon layer, additive manufacturing facilitates the production of lightweight, high-strength components tailored for specific applications in industries such as aerospace, automotive, and healthcare, pushing the boundaries of what's achievable in composite design and fabrication.

ESSENTIAL READING

VIEW ALLAvoiding pitfalls in the design of LFAM composite components

Recoat temperature, part orientation and bead geometry are some key design variables to consider for a successful and reliable large-format additive manufacturing (LFAM) process.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

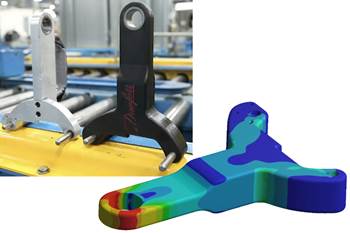

Read MoreHow to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

Read MoreContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

WatchKnowledge Centers

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORELatest Additive Manufacturing News And Updates

CEAD, RusselSmith to bring LFAM to Africa in localization efforts

Collaborative efforts will help businesses across West Africa improve uptime, reliability and supply chain efficiency while reducing environmental impact.

Read MoreStack3D invests in, integrates CEAD Hybrid Flexbot

Stack3D pairs the LFAM FlexBot with its own R&D and materials processing capabilities to offer rapid, end-to-end production from prototyping to low-volume manufacturing.

Read MoreCaracol opens up Texas HQ and LFAM production center

The European company fires up its North American manufacturing capabilities to support U.S. customers, build its capacity and to achieve faster, more direct innovation and delivery.

Read MoreTechmer PM HiFill GF-PET material system bridges low, high-temp tooling gap

GF-PET compound delivers dimensional accuracy, thermal stability and accessible shape compensation data for high-performance 3D printed tooling applications.

Read MoreIACC NODE, Lamáquina enable functional 3D printed composite boat

Asket, the student team’s first project, is a custom, one-piece vessel featuring a 3D printed hull, real-time sensor function and adaptive robotic control.

WatchScaled Composites Model 437 aircraft to be flown for Beacon autonomy testbed

Northrop Grumman subsidiary part of Digital Pathfinder development of stealth aircraft with wings using continuous carbon fiber additive manufacturing and determinate assembly.

WatchFeatured Posts

Optimizing a CFRP landing leg demonstrator

MT Aerospace achieves design for manufacturing, integrating multiple elements into one-piece structure using AFP and 3D printed tooling to meet time and budget constraints.

WatchIn oil and gas, an additive manufacturing standard (API 20T) will aid adoption of composites

Polymer AM equipment maker Roboze sees how the oil and gas industry’s way forward with additive is like that of another high-stakes industry, aerospace, and also different in important aspects.

WatchJEC World 2025 highlights: New thermoplastics, PI fiber, solutions for FR, machining, digitized processes and more

CW senior technical editor Ginger Gardiner discusses latest developments in composites from this year’s show.

WatchVIDEO: Enhancing composite tooling with additive manufacturing

At JEC World 2025, CW editor-in-chief Scott Francis explored the latest advancements in composite tooling with Massivit and Sika.

WatchFIDAMC expands composites R&D into new markets and advanced manufacturing centers

Pioneering technocenter advances RTM, thermoplastic composites, additive manufacturing, microwire, novel lighter weight LSP and more.

Read MorePost Cure: Tool-less direct extrusion enables efficient, complex composite structure development

Backed by AI software, Hans Weber’s large-format 3D printing capabilities resulted in the successful development of a Savonius wind turbine blade in under two hours.

Read MoreFAQ: Additive Manufacturing

What is additive manufacturing in composites?

Additive manufacturing, also known as 3D printing, in composites involves the layer-by-layer deposition of composite materials, such as continuous fibers or chopped fibers within a matrix, to create complex parts or structures.

What types of additive manufacturing methods are used for composites?

Various methods are employed, including Fused Filament Fabrication (FFF), Continuous Fiber 3D Printing (CFF), Binder Jetting, Directed Energy Deposition (DED), and others that selectively deposit materials to build composite parts.

What composite materials can be used in additive manufacturing?

Additive manufacturing processes can work with a range of composite materials, such as carbon fiber-reinforced polymers (CFRPs), glass fiber composites, and even advanced materials like nanocomposites or hybrid composites.

What are the advantages of additive manufacturing in composites?

Benefits include the ability to create complex geometries, lightweight structures, reduced material waste, customization, rapid prototyping, and the integration of functional features within parts.

Are there limitations to additive manufacturing in composites?

Challenges include limitations in scaling for large-scale production, post-processing requirements, ensuring consistent mechanical properties, and the need for advancements in material options.