Hi-Temp Resins

High-temperature resins are specialized materials crucial in composite manufacturing, engineered to withstand extreme heat environments without compromising structural integrity. These resins, like phenolic, epoxy, polyimide, and cyanate ester, exhibit exceptional thermal stability, retaining their mechanical properties at elevated temperatures where traditional materials might degrade. They play a pivotal role in industries such as aerospace, automotive, and electronics, where components face rigorous thermal conditions.

Narrow Your Hi-Temp Resins Search

Latest Hi-Temp Resins Articles

VIEW ALLRegistration opens for CW Tech Days: High-Temperature Composite Solutions

CW Tech Days: High-Temperature Composite Solutions for Defense and Space Applications will take place Oct. 16, 2025.

Read MoreHTMS joins Mobilise accelerator program to advance its CMC materials

High Temperature Material Systems has developed low-temperature cure prepregs for ceramic matrix composite (CMC) parts offering lightweight and thermal/fire protection up to 1000°C.

Read MoreExpanding high-temperature composites in India and the U.S.

Azista USA offers polymers and processes for carbon/carbon and other CMC, including novel hot-melt phenolic and phthalonitrile prepregs for faster cycle times, alternative solutions.

Read MoreCall for abstracts: CW Tech Days to explore high-temperature composite solutions

The fall 2025 installment of CW’s Tech Days online event series will cover high-temperature composite solutions for defense and space applications.

Read MoreHexcel introduces mid-temp Flex-Core HRH-302 honeycomb core

Bismaleimide (BMI) option to serve complex curvatures and thermal management needs of military, commercial and UAM aircraft.

Read MoreRaw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.

Read MoreKnowledge Centers

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORE

ÂÌñÏ×ÆÞ’s CW Tech Days: Infrastructure event offers a series of expert presentations on composite materials, processes and applications that should and will be considered for use in the infrastructure and construction markets.

LEARN MORELatest Hi-Temp Resins News And Updates

Monadnock HTAC Veil protects GFRP equipment against corrosion

Binder-free ECTFE-apertured reinforcement maintains a high resistance against chemicals and abrasion at high temperatures, extending performance and integrity of composite systems.

Read MoreAOC, Büfa expand distribution partnership

Through newly formed Büfa Composites Austria, customers in southeast Europe will have access to resins, gelcoats and auxillary materials.

Read MoreUniSQ fire-retardant resins development bolster bushfire mitigation

The University of Southern Queensland has received funding to be used in the development of cost-effective composite resins to increase the resilience of wind turbine blades against bushfire exposure.

Read MoreToray, Specialty Materials strengthen partnership for next-gen aerospace applications

Commercial partnership enables novel solution innovations with domestically produced, high-quality products within the U.S. supply chain.

Read MoreCAMX 2022 exhibit preview: Renegade Materials Corp.

Renegade Materials is promoting its high-performance prepreg, RTM resin and adhesive products for use in demanding aerospace applications.

Read MoreSicomin supports large-scale interior project for Museum of the Future

Sicomin aided Dubai-based Advanced Fiberglass Industries with its bio-based gelcoats and resins to meet challenging structural and fire safety specifications defined for more than 200 double-curved entrance lobby panels.

Read MoreFeatured Posts

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

WatchPlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

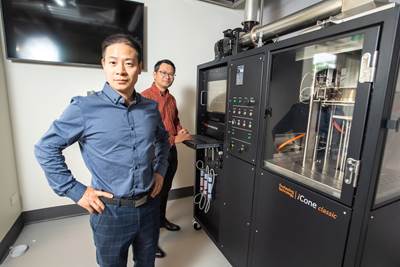

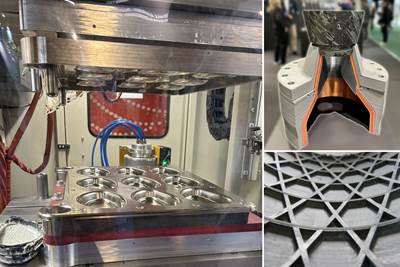

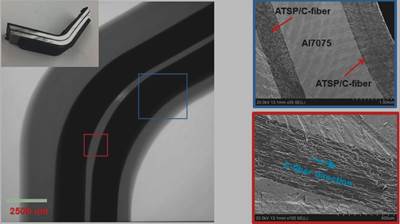

Read MoreNew polymer expands composites options in demanding environments

Aromatic thermosetting copolyester offers unique properties, availability in multiple form factors.

Read MoreComposites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

WatchFlexible, induction-based heating for thermoplastic composite part repair

Spinning off from a German Aerospace Center (DLR) research project, msquare GmbH’s technology aims to innovate and enable repair for high-temperature thermoplastics.

Read More