Core Materials for Composites

Composite core materials serve as the central structural component in composite structures, providing stability, strength, and support while often contributing to the overall lightweight nature of the final product. These cores, typically made of materials like foam, honeycomb structures, or balsa wood, are sandwiched between layers of composite skins to form a composite panel. Their inherent properties—such as high strength-to-weight ratios, excellent insulation, and impact resistance—make them integral in various industries, including marine, aerospace, and construction, where weight reduction and structural integrity are paramount. The choice of core material plays a crucial role in determining the performance and characteristics of the composite structure.

Latest Core Articles

VIEW ALLCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreRevolutionizing space composites: A new era of satellite materials

A new approach for high volumes of small satellite structures uses low-CTE, low-cost CFRP cellular core, robust single-ply skins and modular panel systems to cut lead time, labor and cost for reflectors, solar arrays and more.

Read MoreORGANIC project to 3D print bio-inspired structures with bio-based materials

EU-funded Horizon Europe project tackles lower production cost, enhanced sustainability and first-time-right parts fabrication through the fusion of biology, additive manufacturing and AI.

Read MoreFoamed plastics are well suited for CFRP core applications

CAMX 2025: Sekisui Kasei USA presents ST-Eleveat RNW E foamed plastic and ST-Foamac rigid foam board products designed to support composite core needs.

Read MoreStar Composites begins operations in Spartanburg

The start of carbon fiber multiaxial fabrics manufacturing, as well as relocation of Sky Advanced Materials, Marex and Carbon Core under the Star Composites brand, will further support customers.

Read MoreHybrid composite architecture enables rigid wind propulsion solution for maritime decarbonization

GT Wings’ AirWing leverages aerospace engineering principles combined with hybrid glass and carbon fiber composite construction to deliver up to 30% fuel savings through compact, deck-compatible wind propulsion.

WatchKnowledge Centers

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORE

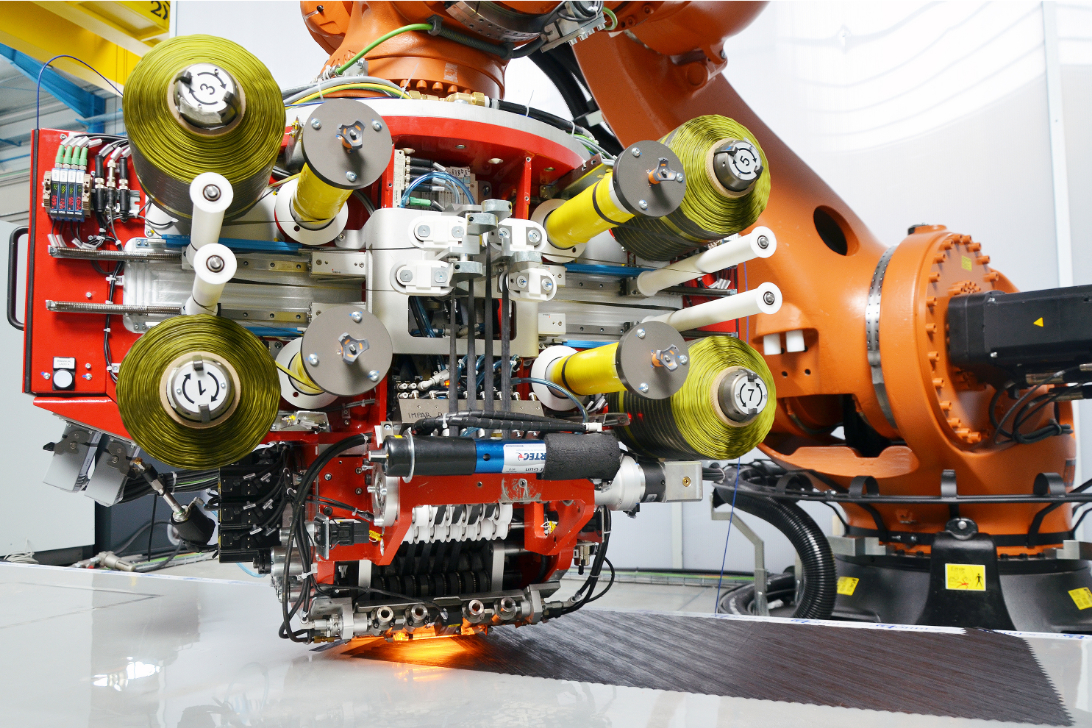

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORELatest Core News And Updates

Airbus to design, build ESA ExoMars rover lander platform

The resurrected Rosalind Franklin composite rover mission’s key systems will be upgraded with support from the TAS, ESA and NASA for a planned launch in 2028.

Read MoreNorco delivers GFRP hard hulled riverine craft for BAE Systems

Norco’s broad-ranging materials and manufacturing expertise revitalize UK MOD legacy craft, providing a solution for future defense and communications sector projects.

Read MorePVC foam core combines reliability with environmental sustainability

JEC World 2025: Maricell will have its own branded booth to present three new MYcell products targeting various sector requirements and sustainability initiatives.

Read MoreComposite, adhesive and core solutions focus on performance, reducing carbon footprint

JEC World 2025: Gurit celebrates 190 years with a display of its product variety — from Spabond 400, resins, prepregs and Gurit PET to BalsaFlex, Opticore and other core systems.

Read MoreDiab achieves mass balance certification, introduces bio-based PVC

As part of its ISCC Plus certification, guaranteeing traceability, Diab is basing all Advanced kits on mass-balanced fossil-free PVC starting in March.

Read MoreComposites portfolio targets thermoplastics, flame-retardant solutions

JEC World 2025: Avient showcases its portfolio of advanced composites and engineered fiber solutions, including its Hammerhead FR flame-retardant thermoplastic composite panels.

Read MoreFeatured Posts

Infused sandwich window frame components help double-decker buses meet weight targets

Prototype GFRP parts were evaluated by Spanish bus manufacturer Carrocerías Ayats as an initial move toward lighter, more efficient, more automated parts and processes.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MorePUR composite sandwich panels for 3D automotive parts, high-volume panels and more

At its U.S. sites, Ascorium produces glass fiber/PUR 3D parts via semi-automated molding, high-volume flat panels via a continuous line while working toward bio-based PUR and recycling.

WatchVIDEO: Precision fabrication of honeycomb materials

MachineTek showcases its precision fabrication of honeycomb materials at CAMX 2024.

WatchComposite SIPs for more affordable, efficient and sustainable buildings

LiteSIP panels and modules enable framing in days, cutting structural labor and total cost by up to 70% and 30%, respectively, while increasing energy efficiency and durability.

Read MoreGuidance for the thermoforming process

A briefing on some of the common foam core material types, forming methods and tooling requirements.

Read More