Braiding in Composites

Envisioning high-volume, 100% composite wheels

Vision Wheel debuted its first carbon fiber composite wheel at CAMX 2021, claiming its low-cost, high-volume process can be scaled up for performance vehicles, UTVs and — ultimately — passenger EVs.

Hannah Mason

Technical Editor, ÂÌñÏ×ÆÞ

Teijin Carbon, A&P Bimax TPUD braided fabric meets scalable composites manufacturing goals

A combination of Teijin Carbon’s UD thermoplastic tapes and A&P Technology’s braided fabrics translates into a PAEK biaxial fabric with minimal crimp, high drapability and other rate-enabling qualities.

Read MoreHexcel, A&P collaborate with NIAR to develop FAA certification framework for overbraided structures

Acceptable composite specifications, design data and methodology will enable affordable, high-rate structure manufacturing for DOD aircraft.

Read MoreComposite Braiding awarded for TPC twin track cantilever support

Railway infrastructure cuts weight by 84%, carbon emissions by 80% and installation time by 50% while automated process offers ≥90% lower labor costs, waste and energy use versus traditional composites manufacturing.

Read MoreBraided composites enable low-cost, high-rate fabrication

CAMX 2025: A&P Technology highlights its QISO and slit tape thermoplastic material capabilities through customer examples and industry applications.

Read MoreAerospace prepregs with braided reinforcement demonstrate improved production rates, cost

A recent time study compares the layup of a wing spar using prepreg with A&P’s TX-45 continuous braided reinforcement versus traditional twill woven prepreg.

Read MoreCorebon, Composite Braiding partner to enhance TPC manufacturing

Collaboration aims to overcome production limitations with tubular thermoplastic composites (TPC) by using induction-heated tooling and high-quality commingled braids.

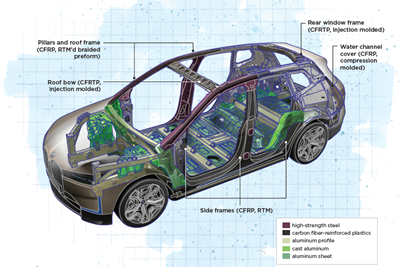

Read MoreBMW rolls out multi-material Carbon Cage with 2022 iX vehicle line

For its new battery-electric iX sports activity vehicle, BMW combines CFRP strategies from previous i3, i8 and 7-Series designs and adds CFRTP for a lightweight, rigid frame.

Hannah Mason

Technical Editor, ÂÌñÏ×ÆÞ

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreNoble Gas Systems 350-bar conformable pressure vessels pass HGV2 standard tests

Conformable tanks with new materials pass technical tests for hydrogen storage, to compete with Type IV pressure vessels using CFRP.

Read MoreCAMX 2021 exhibit preview: Revolution Composites

Revolution Composites’ triaxial braiding process uses a wide range of fibers for for thrusters, nozzles and conical shapes in spaceflight.

Read MoreCAMX 2021 exhibit preview: A&P Technology

A&P Technology’s new product offerings include slit tape thermoplastic fabrics that can be braided into fabrics up to 60 inches wide.

Read MoreDigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms

AMRC aids R&D program including foam thermoforming, complex braiding, thermoplastics and digital twin/thread for higher performance, lower weight with first applications in process.

Read MoreNWCC, Cygnet Texkimp collaboration to advance data on winding capability for composite parts

Research project to demonstrate damage tolerance and impact resistance of composite parts manufactured with new multi-axis winder and 3D winding technologies for further development and commercialization.

Read MoreComposite-metal joining, braided preforms enable next-generation aircraft design

Collins Aerospace invests in new joining, preforming and infusion techniques to target aircraft design needs for reduced weight and lower-cost manufacture.

Hannah Mason

Technical Editor, ÂÌñÏ×ÆÞ

Universal Hydrogen Series A funding to build and test full-scale hardware for hydrogen commercial aircraft

$23.5 million in funding to set Universal Hydrogen on a path to have carbon-free airplanes using composite tanks in commercial service by 2025.

Read MoreComposites protect subsea cables for offshore wind power

Balmoral uses FRP to improve installation, performance and service life while reducing cable failures in rough seas.

Read MoreHP-RTM as a means to reduce hydrogen tank packaging space and cost

BBG Gmbh & Co. KG has developed molds for producers of type IV CFRP tanks, integrating automation and sensors for faster, cheaper production of adjustable-length hydrogen storage cylinders.

Read MoreCollins Aerospace invests in braiding technology, secures funding for next-gen components

The multi-axis composite braider will be used to prove out production for complex-shaped components like pressure vessels, battery enclosures and more.

Read MoreHawthorn Composites awarded structural inlet duct manufacturing contract

Manufacture of inlet ducts for Kratos unmanned combat aerial vehicle involves an automated dry fiber overbraiding process, VARTM infusion and oven cure.

Read MoreCarbon fiber windsurf fin incorporates Sicomin bio-based epoxy resin

Sicomin GreenPoxy 33 meets high-performance windsurfing fins requirements, accommodating significant loads, high torsion stiffness and flexibility.

Read MoreBraided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

Hannah Mason

Technical Editor, ÂÌñÏ×ÆÞ

Universal Hydrogen uses dry braided carbon preform tanks as part of plan to decarbonize aviation

Twin-tank module offers low capex option for regional carriers to convert to clean fuel.

Read MoreBBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production

The autonomous concept, sufficient for series production, enables lower investment costs. Up to 15 cylinders can be produced simultaneously per operation.

Read MorePart 2: Performance and safety benefits of prepregs

Returning with his second installment, Brian Bishop discusses the performance and safety benefits to using prepreg, and the value they can bring to composites fabricators.

Read MoreA&P Technology offers virtual tour for National Composites Week

Hosted by the Midwest chapter of SAMPE, the virtual tour will take place Aug. 27 from 4:00 to 5:30 p.m. ET.

Read MoreTeijin Ltd. Tenax carbon fiber qualified for Airbus A320neo

Tenax dry reinforcements non-crimp fabrics and braided fibers will form the skins and stiffeners via automated RTM.

Read MoreRediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

Read More