NWCC, Cygnet Texkimp collaboration to advance data on winding capability for composite parts

Research project to demonstrate damage tolerance and impact resistance of composite parts manufactured with new multi-axis winder and 3D winding technologies for further development and commercialization.

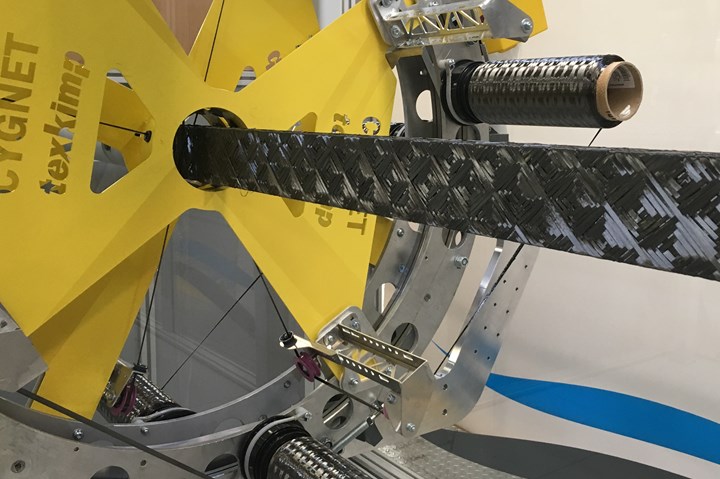

Cygnet Texkimp multi-axis winder. Photo Credit: Cygnet Texkimp.

The Northwest Composites Centre (NWCC, Manchester, U.K.), which is part of the University of Manchester’s Department of Materials, and composites technology company Cygnet Texkimp (Northwich, U.K.) have announced a new research project that will demonstrate the damage tolerance and impact resistance of composite parts manufactured using Cygnet Texkimp’s multi-axis winder (MAW) and 3D winder technologies compared to parts created using braiding and conventional filament winding.

The research will be undertaken by the National Composites Certification and Evaluation Facility (NCCEF), the commercial arm of the Northwest Composites Centre which provides independent, accredited testing and qualifying services to the aerospace, automotive, oil and gas, marine and wind energy industries, including all major primes and Tier 1 and 2 suppliers.

The 3D winder is a robot-mounted, multi-axis, high-speed winding machine. Launched in 2018, Cygnet Texkimp contends that it is the first winding technology of its kind capable of laying down high fiber volumes quickly and accurately to manufacture complex, curved composite components that are strong and repeatable.

The MAW, launched in January 2021, reportedly uses rotating rings to lay down large volumes of material at high speed around a static mandrel. This technology is a development of the 3D winder, says Cygnet Texkimp, but has been optimized for throughput and designed to manufacture long, straight, continuous composite parts with angles and slight curves, including aircraft wing spars, crash protection structures, fuel pipes, tubes, masts and other profiles.

The NWCC has been awarded funding and resources from The Engineering and Physical Sciences Research Council (EPSRC, U.K.) Impact Acceleration Account to carry out and showcase the results of its work.

“The multi-axis winder and the 3D winder are both very new and innovative technologies,” explains Dr. Yan Liu, R&D specialist at Cygnet Texkimp. “Engaging the rigor of a respected, external testing body will help us to gather valuable data and demonstrate their uses and benefits to the industry with the aim of accelerating their adoption.

“We are confident that they [the multi-axis and 3D winder] offer unparalleled levels of speed and throughput at reduced capital cost,” Liu continues. “What the NWCC research will also show us is where these techniques sit in the process hierarchy in terms of the strength and impact resistance of the finished part.”

The project will be led by Professor Potluri, director of the NWCC. Researchers will take a range of composite parts manufactured on the MAW, 3D winder, a braider and a conventional filament winder and carry out a series of tests, including four-point bending, impact and bending after impact testing, to investigate how strength and damage tolerance are affected by the manufacturing technique.

“Using science to investigate and compare manufacturing techniques is increasingly important as composites manufacturers and end-users look for better and more efficient ways to create high performance materials and parts,” says Professor Potluri. “Trials like these are extremely useful not only to validate new technology but to give commercial customers the insights to select the right technology for their business. The main purpose of our research is to quantify how structural performance and damage tolerance can be maximized, depending on the method of manufacture employed.”

This is the second time the two organizations have worked together. In 2018, both took part in a , which focused on a nine-axis winding concept first developed by Professor Potluri. That technology was further developed and commercialized by Cygnet Texkimp to create the 3D winder.

“The University has a key role to play at the interface between academia and industry, supporting the commercialization of innovative concepts that have the potential to transform manufacturing,” says Professor Potluri. “Combining our knowledge and resources with those of a world-class company like Cygnet Texkimp means that together our work can have a real and positive impact on the industry.”

Cygnet Texkimp CEO Luke Vardy will present findings from the research project as part of the CW Tech Days: Composites in the Hydrogen Economy, exploring the role of 3D winding technology in the manufacture of hydrogen storage tanks, May 18, 2021.

Related Content

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More