Injection/Overmolding

Injection or overmolding techniques in composites involve the process of injecting or molding a composite material over a pre-existing structure or component, enhancing its functionalities or adding protective layers. This method allows for the combination of different materials, such as polymers or composite resins, to create a cohesive and integrated final product. It's commonly used to reinforce or encapsulate parts, providing improved strength, durability, and resistance to environmental factors.

Latest Injection/Overmolding Articles

VIEW ALLAnybrid Rav·In system enables inline injection molding functionalization

Rav·In has been developed specifically for functionalization in linear processes such as extrusion, pultrusion or roll-to-roll applications.

Read MoreTrelleborg invests in Innovation Center expansion, remodel

An additional purpose-built space in Delano, Minnesota, by early 2027 adds a visitor center, Swiss machining, injection molding and increased space for automation.

Read MoreKraussMaffei CFP technology enhances glass fiber processing

Patented screw geometry and the ability to separately dose glass fibers and PP into the injection molding machine reduces material cost by 30%, enables consistent quality and flexibility.

Read MoreCustom hydraulic presses promote reliability, material variety and automation features

CAMX 2025: Learn how a custom press from French enhances the composite molding process, equipped to adhere to application/requirement needs.

Read MoreMateri’act launches NAFILean Vision biocomposite

NAFILean materials family blends low-carbon recycled plastics and renewable post-consumer sources like hemp fibers to provide a sustainable, visually appealing solution for automotive parts.

Read MoreEnhanced RCF thermoplastic compounding opportunities grow composites recycling breadth

CAMX 2025: Vartega’s EasyFeed Bundles now come in a wider array of rCF solutions for thermoplastic compounding, in addition to offering joint product development programs and R&D trials.

Read MoreKnowledge Centers

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORELatest Injection/Overmolding News And Updates

Porsche develops TABASKO method for lightweight vehicle series production

Patented carbon fiber-reinforced polypropylene tape-based process supports cost reduction, light weight and thinner walls without sacrificing rigidity.

Read MoreEngel supports composites upcycling research at TH Rosenheim

Engel Group has provided the Rosenheim University of Applied Sciences with a vertical injection molding machine for further R&D into the processing of thermoplastic, recyclable composites and the application of natural fibers.

Read MoreReinforce 3D forms alliance with 3D printing company Spring Srl

Integration of CFIP technology with additive manufacturing will facilitate optimized composites manufacturing and build up CFIP’s scale.

Read MoreEngel opens new Mexico facility, expands injection molding machine production capacity

Mexico is a strategic location for Engel to achieve greater efficiency, responsiveness to market demands and a skilled workforce present and future expansion.

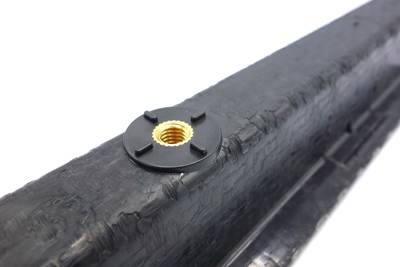

Read MoreReinforce 3D, Bauer Hockey partner for CFIP-optimized sports equipment

Continuous carbon fiber injection process (CFIP) will achieve more durable, high-performance equipment for every athletic discipline.

Read MoreReinforce 3D receives €1.2 million investment to support 2025 growth plans

Production, R&D team and strategic market expansion will scale up the company’s continuous carbon fiber injection technology, composite capabilities.

Read MoreFeatured Posts

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

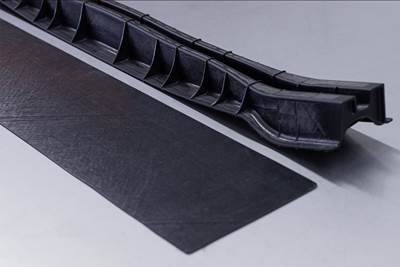

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read More