Siemens adds AI to Simcenter Testlab, reinventing modal testing and analysis

Simcenter Testlab, already used with composites, now uses intelligent test automation and AI assistance to execute physical testing workflows faster, smarter and earlier in structural design programs.

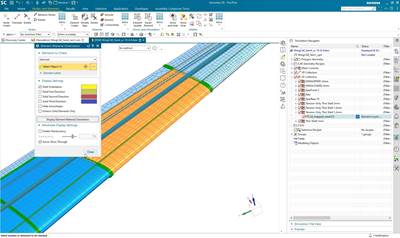

The latest update to Simcenter Testlab includes intelligent test automation and AI assistance. Source (All Images) | Siemens Digital Industries Software

Siemens Digital Industries Software (Plano, Texas, U.S.) has announced the latest updates to its Simcenter Testlab software, including new AI-assisted workflows that accelerate modal analysis processes, making them up to seven times faster while reducing the personnel needed to perform physical impact testing. Updates also bring automated data capture and processing, improving data quality and consistency across all testing phases — enabling engineers to test faster, smarter and earlier.

Siemens is leveraging AI to streamline processes and workflows, minimize manual tasks and accelerate time to market throughout the engineering life cycle, says Jean-Claude Ercolanelli, senior vice president, simulation and test solutions for Siemens Digital Industries Software. “The latest enhancements in Simcenter Testlab illustrate our approach to integrating AI to transform how teams conduct, manage and interpret physical testing. We are leading a significant shift in engineering practices, from design and development through to the essential stages of physical testing.”

Siemens’ Simcenter Testlab AI-assisted modal testing capability speeds the modal analysis via enhanced automated mode selection and validation combined with a unified modal analysis dashboard that streamlines the modal testing workflow. In addition, intelligent sensor placement and automated hit selection simplifies the impact acquisition and reduces personnel required.

Enhanced testing and analysis tools

Transfer Path Analysis (TPA). New automation features and processing capabilities in Simcenter Testlab cuts overall analysis time by 40%, making sophisticated noise, vibration, harshness (NVH) predictions more accessible to less experienced users.

ISO 20270-compliant solution. Cuts the time for component characterization from weeks to hours through automated acquisition of blocked forces and impedance frequency response functions (FRFs) with automated component model extraction solution using Simcenter physical testing hardware and new Simcenter Testlab Automated Component Model Extractor software.

Streamline test preparation. Use predefined sequences to automate data processing and validation in Simcenter Testlab Schedule Designer to help ensure complete data traceability and virtually eliminate the risk of incomplete or inconsistent test data.

In this latest update, Simcenter SCADAS RS can now be combined with Simcenter SCADAS Recorder, Mobile and Lab systems to expand channel counts but also upgrade capabilities of existing investments.

The latest update also seamlessly transfers test plans defined in the Schedule Designer to the data acquisition system Recorder App. This integration provides clear, wireless, tablet-based instructions to operators and enables immediate data validation and processing and thus reduces errors.

In keeping with Siemens’ philosophy of openness, Simcenter SCADAS RS now also enables export of data in universal or third-party formats, so the system can work with other software platforms for data processing and analysis.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Siemens software chosen for JetZero BWB aircraft concept, launches Xcelerator updates

Aviation startup will use the Xcelerator platform to achieve its aircraft vision. Other Siemens collaborations deliver software additions to deliver, democratize industrial AI for small companies, startups.

Read MoreSimcenter software update highlights aircraft wing skin optimization

Expanded aerospace capabilities in Siemens software portfolio performs more rapid margin of safety calculations and reduces simulation preprocessing up to 80%.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More