Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer-Gesellschaft

Wiener Strasse 12

Bremen, 28359 DE

49 421 2246 0

info@ifam.fraunhofer.de

CONNECT

About Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Offers research and development in the field of adhesive bonding technology and surfaces; shaping and functional materials; automation and production technology. It develops system solutions for adhesive bonding, plasma, paint and FRP technology and customized solutions, using optimized production processes.

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM Supplies the Following Products

- Composites - Materials & Product Testing & Analysis Equipment

- Composites Materials

- Composites Process Development

- Composites Structural Design

- Other

- Structural testing

- Training & Workforce Development Services/Software

- Universities, Colleges & Research Centers

Editorial, News, and Products

-

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

-

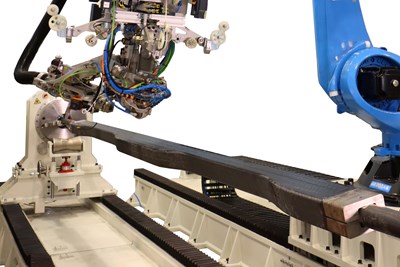

Fraunhofer IFAM MTC closes gap between industrial robots, machine tools

Machine tool robot (MTC) features improved milling kinematics that enable versatile, efficient and high-precision machining of composites and hard metals with a manufacturing tolerance of up to 0.1 millimeter.

-

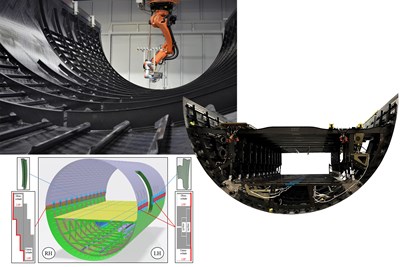

Assembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

-

Fraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

-

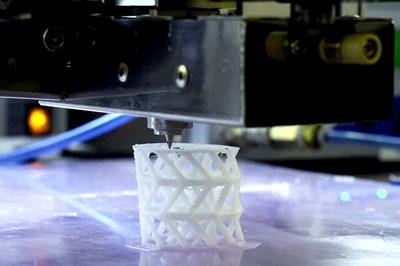

SCABAEGO project develops bioactive composite that supports healing of broken bones

Fraunhofer IFAM researchers and partners combine biodegradable polymer polycaprolactone and bioactive glass to 3D print custom-fit structures for bone fracture sites.

-

OptiBlade project increases rotor wind blade production efficiency

Successful completion of project led by Fraunhofer IFAM sees the development of stretch-formable PeelPlas film for release agent-free demolding of FRP components.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

Fast-FlexMont2 project targets optimized, large-structure CFRP assembly

Advanced measuring and referencing methods, highly precise positioning technologies and continuous digital process control by Fraunhofer IFAM demonstrate automated rudder hinge assembly.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

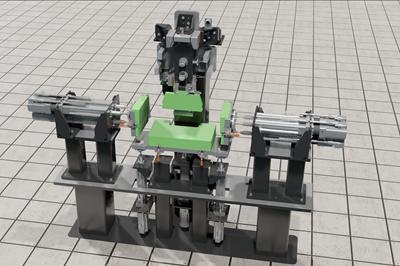

German UniFix project develops mobile holding fixture to enhance production efficiency of large CFRP structures

Fraunhofer IFAM and Airbus Operations in Stade demonstrate reduced manual handling and non-productive time in flow-oriented manufacturing of vertical tail plane.

-

JEC World reveals 2022 Innovation Awards finalists

Innovation Awards celebrate successful projects and fostered cooperation between players in the composite industry, with 30 finalists in ten categories.

-

Developing next-gen, smart engine composite fan blades

EU-funded MORPHO project will use embedded sensors, data-driven hybrid twins and machine learning to increase RTM yield, improve damage-tolerant design, achieve SHM and 100% recycling.

-

Broetje-Automation delivers EcoPositioners for automated built-in stress-compliant joining in aircraft fuselages

Modularized and highly precise positioning system increases assembly accuracy and speed, enables digitization of CFRP aircraft components assembly for factory of the future.

-

Fraunhofer IFAM automates pre-assembly of CFRP fuselage frames

Positioning and drilling end effector for automated, high-precision and quality-assured pre-assembly developed with Airbus in German-funded “Tempo” sub-project.

-

Proving out LMPAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test LMPAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

-

Fraunhofer IFAM researchers awarded Wright Brothers Medal for industrial robot research

The publication describes the use of an external laser tracker measuring system to improve the accuracy of industrial robots.

-

Hybrid thermoplastics give load floor impact strength

Project leads to development of new compression process for selective application of D-LFT on UD tape laminates.

-

The future of CFRP aerostructures assembly

Metrology, robotics and inline inspection cut cost, reduce shimming and enable future automated production of three vertical tail planes per day.

-

Composite Application Center launches in Singapore

An international group of companies has announced the launch of a Singapore based Composite Application Center to support the composites industry through combined expertise and facilities.

-

SMC: Old dog, new tricks

A sheet molding compound renaissance highlights new reinforcements, new fillers, new matrices, new opportunities.

-

CW Plant Tour: Composite Technology Center, Stade, Germany

A cornerstone of Germany’s CFK Valley, CTC pushes composites forward via automation, recycling, digital thread-based manufacturing and more.

-

Composite engine piston cylinder housings

Phenolic BMC could replace aluminum in car/motorcycle engine housings.

-

PMI foam core outperforms honeycomb in infused nose landing gear doors

The results of Airbus (Toulouse, France) subsidiary Composite Technology Centre GmbH (CTC, Stade, Germany) studies in 2013 to find more productive but less costly methods of fabricating carbon fiber-reinforced polymer (CFRP) sandwich constructions.

-

PMI foam core outperforms honeycomb in infused nose landing gear doors

The results of Airbus (Toulouse, France) subsidiary Composite Technology Centre GmbH's (CTC, Stade, Germany) studies in 2013 to find more productive but less costly methods of fabricating carbon fiber-reinforced polymer (CFRP) sandwich constructions.

-

2013 JEC Europe new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.