Mechanical testing of ceramic matrix composites

Today’s CMC materials, robust and resistant to high temperatures, provide their own set of challenges when determining their performance through mechanical testing.

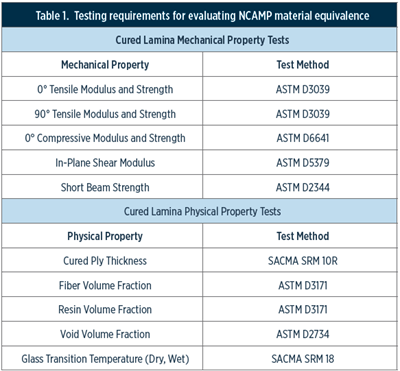

Figure 1. Double-notched shear test methods for determining the interlaminar shear strength of CMCs. Source (All Images) | Christian Wilson

Ceramics are a class of nonmetallic materials traditionally formed by high-temperature heating of natural materials, such as clay-based tiles, bricks and pottery. In contrast, today’s advanced ceramics are made from engineered inorganic materials such as alumina (Al2O3), silicon carbide (SiC) and silicon nitride (Si3N4) for use at temperatures above 1200°C. They are used in a variety of high-temperature aerospace, automotive and industrial applications. Their manufacturing process includes sintering in a kiln between 1500-1700°C, which densifies the material and increases its strength and hardness.

The strength and damage tolerance of advanced ceramics may be increased by the addition of ceramic reinforcing fibers, resulting in ceramic matrix composites (CMCs). The most common ceramic fibers used in CMCs include SiC, Al2O3, mullite (Al2O3SiO2), carbon (C) and silica (SiO2). Common matrices for CMCs include C, SiC and Al2O3 while ultra-high temperature CMCs (UHTCMCs) often use carbides, borides and nitrides of transition metals such as tantalum (Ta), hafnium (Hf) and zirconium (Zr).

In addition to providing increased strength properties, fiber-reinforced CMCs exhibit markedly improved toughness and damage tolerance compared to traditional ceramics, significantly reducing their inherent brittleness. Additionally, their ability to retain mechanical integrity at elevated temperatures, often exceeding 1200 °C, makes them ideal candidates in a variety of aerospace and other applications. However, the mechanical testing of CMCs presents significant challenges when compared to the testing of metals or polymer matrix composites (PMCs). In this column, I’ll review the more commonly performed mechanical test methods for CMCs.

Testing temperatures and fixturing

CMCs are engineered for high-temperature applications, often requiring mechanical testing at temperatures exceeding 1000°C to validate their performance. However, these high-temperature testing requirements present technical challenges when designing suitable test fixturing, as fixture components must not warp, yield, fracture or undergo excessive deflection at high temperature.

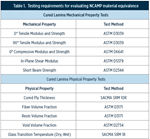

Table 1 lists all of the current ASTM mechanical test methods for CMCs published by ASTM Subcommittee C28.07 on Ceramic Matrix Composites, which operates under Committee C28 on Advanced Ceramics. Included in the table is the maximum test temperature and the recommended test fixture materials to be used in each test method. While elevated temperature testing of PMCs is routinely performed between 121°C and 177°C (250–350°F) using metallic test fixtures, they begin to lose mechanical integrity above 600-700°C, making them unsuitable for the elevated temperature requirements of CMC testing.

Table 1. ASTM C28.07 mechanical test methods for CMCs.

While the use of ceramic test fixturing is of interest for high-temperature mechanical testing of CMCs, it is challenging and expensive to fabricate common test fixture designs using ceramic materials. These materials are difficult to machine, especially when tight tolerances or complex geometries are required. Their inherent brittleness also makes them highly susceptible to fracture during testing, for example, due to concentrated loads, misalignment or minor surface defects. And once damaged, ceramic fixtures typically cannot be repaired or repurposed.

Thus, ceramic test fixtures are often poorly suited for high temperature CMC testing. As a result, metallic fixtures made from nickel-based superalloys, molybdenum or tungsten, particularly with high-temperature coatings or thermal isolation strategies, are often preferred for these applications.

Due to test fixture temperature limitations, some ASTM test methods for CMCs restrict testing to ambient conditions (25°C), providing only baseline mechanical properties. Four commonly used types of CMC mechanical testing — tension, compression, shear and flexure — are described below.

Tension testing

ASTM C13591, originally published in 2005, focuses on elevated-temperature tensile testing of continuous fiber CMCs. In addition to the use of standard rectangular cross-section specimens, the test method was revised in 2018 to include the use of specimens with tapered widths in the central gage section as well as the combination of face loading and pin loading in the specimen gripping regions. These changes were intended to reduce the occurrence of specimen failures in the gripping regions and increase stress uniformity in the central region where strain measurements are used to determine the elastic modulus.

Perhaps the greatest challenge in obtaining good tensile test results is the design of suitable grips that properly grip the specimen at high temperatures while minimizing stress concentrations. However, several companies now offer high-temperature tensile grips to accommodate flat, button-head and threaded-end round specimens at temperatures ranging from 1000°C to 1600°C.

Additionally, ASTM C12752 addresses tensile testing of continuous fiber-reinforced CMCs at ambient temperatures. This test method includes both rectangular and tubular specimens.

Compression testing

ASTM C13583 focuses primarily on end-loaded compression testing of continuous fiber CMCs using solid rectangular cross-section specimens. While tabbed specimens are not the central focus of the standard, they may be used in specialized setups to improve load transfer and reduce stress concentrations at the specimen ends. The standard also describes alternative specimen geometries that include cylindrical cross-sections and tapered gage sections as well as the use of frictional face-loading grips. The scope of the standard is limited to testing at ambient temperatures.

Currently, there are no standardized test methods that address elevated-temperature compression testing of CMCs. However, ASTM E2094 describes a compression testing procedure for metallic materials at elevated temperatures, which can be modified for use with CMCs. In this procedure, the hardened steel platens are replaced with high-temperature compression fixturing capable of withstanding the elevated test temperatures.

Shear testing

ASTM C14255 describes a double-notched shear test configuration used for determining the interlaminar shear strength of continuous fiber-reinforced CMCs at elevated temperatures up to 1000°C. This upper temperature is based on the temperature limits of both the material being tested and the test fixture material. As a result, the test fixturing is commonly constructed from nickel-based superalloys such as Inconel 625. The standard rectangular specimen has two opposing and offset notches machined halfway through its thickness on opposite faces as shown in Fig. 1a. The notches are spaced 6 millimeters apart to concentrate shear stress between them, producing an interlaminar shear failure under uniaxial compression loading.

Additionally, ASTM C12926 describes two test configurations for shear testing CMCs at ambient conditions. The first configuration uses a double-notched shear specimen geometry that’s identical to the ASTM C1425 double-notched shear specimen as shown in Fig. 1. However, a simplified test fixture design (Fig. 1b) is possible for determining the interlaminar shear strength of CMCs at ambient temperature. The second ASTM C1292 shear testing procedure uses the same Iosipescu shear test method that is commonly used for in-plane shear testing of PMCs according to ASTM D53797. The specimen is loaded using an asymmetric four-point bend configuration, which induces shear stresses at the specimen centerline between the notches.

Flexure testing

ASTM C13418 is used to determine the flexural strength and modulus of CMCs using either three-point or four-point loading configurations. Two loading configurations may be used for four-point loading, differing only in their upper span length between the two loading cylinders: either one-half or one-third of the lower support span length. Additionally, CMCs often experience progressive failures under flexure loading, including matrix cracking and delamination, allowing for failure mode comparisons across multiple materials. While flexure testing results are often used for material screening, quality control or for comparative testing, ASTM C1341 advises against the use of flexure test data for design values.

ASTM Subcommittee C28.07 on Ceramic Matrix Composites continues to develop new test methods as well as update existing test methods for CMCs. These standards help ensure the reliability and consistent performance of CMCs, particularly when they are used in high-temperature environments.

References

1 ASTM C1359-18(2025), “Standard Test Method for Monotonic Tensile Strength Testing of Continuous Fiber-Reinforced Advanced Ceramics With Solid Rectangular Cross Section Test Specimens at Elevated Temperatures,” ASTM International (W. Conshohocken, Pa., U.S.), 2025.

2 ASTM C1275-18(2025), “Standard Test Method for Monotonic Tensile Behavior of Continuous Fiber-Reinforced Advanced Ceramics with Solid Rectangular Cross Section Test Specimens at Ambient Temperature,” ASTM International (W. Conshohocken, Pa., U.S.), 2025.

3 ASTM C1358-18(2025), “Standard Test Method for Monotonic Compressive Strength Testing of Continuous Fiber-Reinforced Advanced Ceramics with Solid Rectangular Cross Section Test Specimens at Ambient Temperatures,” ASTM International (W. Conshohocken, Pa., U.S.), 2025.

4 ASTM E209-18, “Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates,” ASTM International (W. Conshohocken, Pa., U.S.), 2018.

5 ASTM C1425-19, “Standard Test Method for Interlaminar Shear Strength of 1D and 2D Continuous Fiber-Reinforced Advanced Ceramics at Elevated Temperatures,” ASTM International (W. Conshohocken, Pa., U.S.), 2019.

6 ASTM C1292-22, “Standard Test Method for Shear Strength of Continuous Fiber-Reinforced Advanced Ceramics at Ambient Temperatures,” ASTM International (W. Conshohocken, Pa., U.S.), 2022.

7 ASTM D5379/D5379M-19 (2021), “Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method,” ASTM International (W. Conshohocken, Pa., U.S.), 2021.

8 ASTM C1341-13(2023), “Standard Test Method for Flexural Properties of Continuous Fiber-Reinforced Advanced Ceramic Composites,” ASTM International (W. Conshohocken, Pa., U.S.), 2023.

Related Content

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

Read MoreOptimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreRead Next

Material equivalence testing in shared composites databases

In response to traditionally proprietary polymer matrix composites (PMC) qualifications, NCAMP continues its efforts to make material property databases publicly available.

Read MoreCIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

Read MoreExpanding high-temperature composites in India and the U.S.

Azista USA offers polymers and processes for carbon/carbon and other CMC, including novel hot-melt phenolic and phthalonitrile prepregs for faster cycle times, alternative solutions.

Read More