Modular approach to material card development of composites

Forward Engineering GmbH walks through a modular testing and simulation approach for automotive/aviation composites enabling more accurate material selection earlier in the design phase.

In response to limitations within material testing and simulation in early design stages for automotive/aviation composites, Forward Engineering GmbH has developed a modular approach to testing and material card creation. Source (All Images) | Forward Engineering

Fiber-reinforced polymer (FRP) composites have become indispensable in automotive and aviation industries, offering exceptional strength-to-weight ratios, design flexibility and tunable properties. However, their full potential is often unrealized due to challenges in accurately modeling their mechanical behavior for simulations. It is particularly difficult to predict the behavior in crash or impact scenarios, as composites can exhibit a high strain rate dependency. Moreover, the inherent variability in material properties and a lack of standardized input data complicate the creation of reliable material cards, forcing engineers to rely on high safety factors. This conservative approach undermines the weight-saving advantages of composites and stifles innovation.

Thus, more accurate structural simulations with material cards that are capable of capturing the complex behavior of composites can help enable their full lightweight potential. However, usually not all material data is available and required in early design phases.

To address these challenges, a modular framework has been developed by Forward Engineering GmbH (Munich, Germany) that systematically guides engineers through the generation of simulation-ready data. The methodology begins with basic stiffness modeling and progresses to advanced scenarios like impact resistance and post-failure behavior, enabling temperature or strain rate-dependent structural simulations at component- or full-scale level. This stepwise approach allows engineers to initiate simulations in early design stages with preliminary data and refines accuracy as the design evolves, incorporating additional test results over time.

In the automotive industry, this approach supports the early concept stages with basic simulations to achieve a load path-oriented design. In this phase, stiffness- and strength-driven simulations are usually sufficient. For later detailed design, the material card can be expanded with failure and damage models. Furthermore, for crash validation, the material card is extended with a strain rate-dependent behavior.

The aviation industry’s relentless pursuit of lightweight solutions makes accurate material cards essential for maximizing the weight-saving potential of composites. For this industry, Forward Engineering’s approach provides a rigorous framework for validating material behavior at every development stage, but also from initial design to final certification. This method is particularly effective in accounting for real-world material variability — such as production batch differences and environmental effects — through controlled, data-driven refinement. By progressively reducing uncertainty in performance predictions, it enables precise modeling while maintaining the highest safety standards.

Module 1: Basic mechanical properties and early simulation

Module 1 (see sections 1A in Figs. 1-2) serves as the foundation of Forward Engineering’s modular framework, delivering fundamental elastic and strength properties required to model composite parts up to initial failure. These properties are derived from standard coupon-level tests in tension, compression and shear. For early stage design tasks — particularly those not involving crash- or failure-level loads — this basic material card provides sufficient accuracy, making it ideal for stiffness-driven applications and initial concept evaluations.

Figure 1.

Optional extensions to Module 1 include hygrothermal testing to assess temperature and humidity effects, as well as damping properties for noise, vibration and harshness (NVH) simulation. These extensions allow the same foundational data to be repurposed for other domains, such as dynamics and vibration control. For instance, predicting aircraft wing behavior under extreme temperature cycles or optimizing automotive body panels for seasonal weather variations while managing structural vibrations becomes more efficient.

Module 1b (see section 1B in Figs. 1-2), a subset of Module 1, introduces crush screening — a cost-effective method for comparing the crash energy absorption potential of various material combinations, including resins, fiber types and additives. In the automotive sector, this enables early evaluation of crashworthy materials for bumpers or battery enclosures before final geometries are defined. Similarly, in aviation, it supports rapid assessment of impact-relevant structures such as wings or casings, aligning with phased certification timelines. While Module 1b lacks the depth required for full crash or impact simulation, it efficiently identifies promising material systems for further development.

A key advantage of Modules 1a and 1b is their applicability before final part geometry or boundary conditions are established. With this flexibility, development teams are able to begin material selection and simulation work early, accommodating the fast, iterative timelines of the automotive industry and the rigorous, phased development cycles of aviation.

Module 2: Post-failure and crash-level characterization

When applications demand modeling beyond initial failure — particularly for components designed to absorb impact energy — Module 2 becomes essential (see sections 2A and 2B in Figs. 1-2). This stage focuses on characterizing material behavior as damage initiates and evolves.

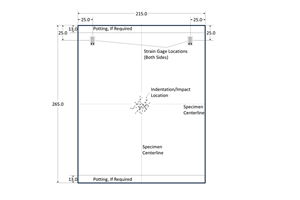

Module 2a employs coupon-level tests, such as compact tension and compression, to evaluate post-first-failure performance. These tests quantify crack initiation, energy release and delamination propagation, providing critical insights for early crash modeling. Module 2b advances to component-level testing, where complex geometries, hat sections or closed profiles are subjected to quasi-static or dynamic loading. These tests, often conducted using three-point or four-point bending setups, simulate multiple interacting failure modes, offering a more realistic representation of crash scenarios.

The distinction between Modules 2a and 2b reflects the escalating complexity of failure modeling in real-world structures. While Module 2a isolates specific failure modes, Module 2b captures their combined effects in integrated parts. Together, they refine material card inputs for higher simulation accuracy — whether validating energy absorption in automotive crash boxes through combined coupon and component tests, or certifying aircraft fuselage panels by correlating delamination behavior from coupon tests with full-scale impact performance.

The modular method’s ability to decouple validation geometry from simulation input ensures data applicability across structurally similar components, enhancing simulation flexibility and reducing redundant testing.

Figure 2.

Module 3: Dynamic effects and high-fidelity crash simulation

In crash-critical applications where strain rate effects and energy absorption dominate design considerations, Module 3 (see sections 3A and 3B in Fig. 1-2) extends material cards with high-strain rate and dynamic crush data.

Module 3a introduces strain rate-dependent material properties through high-speed testing methods like drop tower tests or Split-Hopkinson pressure bars. These tests replicate the rate-sensitive behavior of FRPs under conditions such as automotive crash events or aircraft impact scenarios such as bird strike or tire impact, ensuring high-accuracy simulation at component- or full-scale levels.

Module 3b focuses on axial crushing, the primary failure mode for components like automotive crash tubes. Drop tower testing on generic and part-representative geometries measures energy dissipation under realistic crash conditions, incorporating failure modes unique to high-energy, high-strain scenarios.

The shape and complexity of test specimens in Module 3b are critical, as real-world vehicle or aircraft structures often feature curvature and varying thickness, influencing energy absorption. Module 3b material cards account for these factors, delivering application-relevant yet geometry-transferable simulation inputs.

This level of testing ensures material cards accurately predict not only failure but also energy absorption patterns — whether optimizing an electric vehicle’s (EV) battery enclosure for crash safety or validating the behavior of a turbine blade during bird strike. Such fidelity is indispensable for final-stage validation, regulatory compliance and full-system crash modeling.

Scalable workflow, confident material selection

This modular framework provides a scalable, resource-efficient workflow for simulation-based design with composites. As projects progress, material cards can be expanded without duplicating earlier tests, with each module building on its predecessor to create a seamless pathway from concept to full crash simulation.

By addressing industry-specific challenges — such as automotive cost-efficiency timelines or aviation’s certification phasing — this modular approach accelerates confident material selection. Forward Engineering’s continuous refinement will expand the database of standard materials and deliver ready-to-use toolkits, enabling broader adoption. Ultimately, this methodology empowers the automotive and aviation industries to fully exploit FRPs’ benefits — whether achieving lightweighting targets for EVs or optimizing critical airplane structures without weight penalties.

About the Author

Ganesh Lokanath

Ganesh Lokanath holds a master’s degree in automotive engineering with a focus on composite material processing and simulation, and a bachelor’s degree in mechanical engineering. He has more than 7 years of experience in composite materials, working in both process engineering and simulation. His master’s thesis involved material card development through the characterization of mixed-mode delamination. He has been with Forward Engineering for 3 years and previously worked at a bio-based composites start-up.

Dennis Bublitz

Dr. Dennis Bublitz is leading the group for Simulation Driven Design at Forward Engineering GmbH. He holds a B.Sc. in mechanical engineering and a M.Sc. in aeronautical engineering. In his Ph.D., he focused on composites manufacturing simulations for RTM processes, where he developed his own material model to describe the complex time-dependent and orthotropic behavior of composites. Bublitz has more than 12 years of experience in composite simulations for structural analysis and manufacturing processes. He was involved in countless projects in the automotive and aviation industry, where accurate material cards and high-fidelity simulations were used to design lightweight structures.

Related Content

Damage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Crashworthiness testing of composites: A building block approach, Part 1

Determining the crashworthiness of composite structures requires several levels of testing and analysis, starting with coupon-level crush testing.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More