Development of fracture mechanics test methods for sandwich composites: An update

An update on the CMH-17 Sandwich Disbond Working Group’s sandwich SCB test and two additional sandwich composite fracture mechanics test methods under development.

Figure 1. Modes of fracture and applied loadings. Source (All Images) | Dan Adams

In my May 2020 CW column, I introduced a new test method for measuring the fracture toughness within the facesheet-to-core interface region of sandwich composites. This proposed test method, referred to as the sandwich single cantilever beam (SCB) test, was under development by the Composite Materials Handbook (CMH-17) Sandwich Disbond Working Group. Five years later, the SCB test is in the final stages of ASTM standardization, and two other sandwich composite fracture mechanics test methods are being developed for future standardization. In this column, I will provide an update on the development of these three sandwich composite fracture mechanics test methods.

Fracture mechanics testing of sandwich composites addresses the growth of an existing disbond at the facesheet-to-core interface or a crack within the core material. The property determined from testing is the critical energy release rate, Gc, a measure of the fracture toughness associated with crack growth. This Gc value is used to predict whether a disbond will propagate in a sandwich composite. Because Gc depends on the mode of loading applied during crack growth, different test methods are used to determine the fracture toughness under Mode I (opening), Mode II (sliding) and Mode III (tearing) conditions, as illustrated in Fig. 1. For sandwich composites, the greatest interest lies in Mode I and combined Mode I/Mode II “mixed-mode” loading. Ongoing efforts by the CMH-17 Sandwich Disbond Working Group have sought to develop standardized tests for these two fracture modes, including recent work to adapt the Mode I test method for Mode I cyclic fatigue loading.

The sandwich single cantilever beam (SCB) test

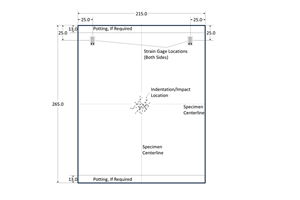

Similar to the ASTM D55281 double cantilever beam (DCB) test for composite laminates, the sandwich SCB test is used to measure the Mode I-dominant fracture toughness associated with the growth of an existing disbond. In this test, an initial facesheet/core disbond is produced along the upper facesheet-to-core interface at one end of the specimen as shown in Fig. 2. The unbonded portion of the upper facesheet acts as a cantilever beam, thus the name “single cantilever beam” test. The lower facesheet is secured to a base fixture using edge-clamps, also shown in Fig. 2. A vertical tensile force is applied using a piano hinge or loading block bonded to the disbonded end of the upper facesheet.

Figure 2. Sandwich single cantilever beam (SCB) testing.

Although crack growth produced during testing is commonly referred to as facesheet/core disbonding, the fracture often propagates within the core material, below the actual upper facesheet/core interface. To ensure Mode-I dominant crack growth, the crack is required to remain within the upper one-fourth of the core thickness and within five facesheet thicknesses from the upper interface. Under these conditions, the test is considered a valid Mode I fracture characterization.

Similar to the ASTM D5528 DCB test for unidirectional (UD) composite laminates, two values of the Mode I fracture toughness, GIc, are measured during testing: an initiation value and a propagation value. However, unlike the DCB test for UD composites, these Mode I fracture toughness values are considered to be structural properties of the as-fabricated sandwich composite, and are dependent on the properties of both the facesheet and the core, as well as the specific fabrication method used.

The SCB fatigue test

The second sandwich fracture mechanics test under development is a Mode I SCB fatigue test to be performed under constant-amplitude tensile fatigue loading. This SCB fatigue test, to be standardized as an ASTM Standard Practice, provides guidance for adapting the standard SCB test procedure to an applied constant-amplitude fatigue loading. The proposed standard practice uses the same specimen geometry, test fixture and loading configuration as in the sandwich SCB test method described above.

Prior to fatigue testing, conventional SCB tests are performed to determine initial values of both specimen stiffness and fracture toughness, as well as to produce a natural precrack for subsequent fatigue loading. A series of sets of constant-amplitude SCB fatigue tests are performed, starting at an applied GImax level equal to 50% of the GIc value from quasi-static SCB testing. The additional sets of SCB fatigue tests are performed using GImax values ranging from 30% to 70% of the quasi-static GIc value.

The sandwich mixed-mode bending (MMB) test

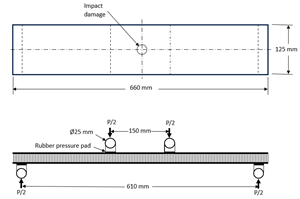

Figure 3. Sandwich mixed-mode bend (MMB) test fixture with specimen installed.

The third sandwich fracture mechanics test currently under development is the sandwich mixed-mode bending (MMB) test. This test method (Fig. 3) is used to determine the fracture toughness of sandwich composites across a range of Mode I-to-Mode II loading ratios. The proposed test method is similar to the existing ASTM D66712 standard that’s used for determining the mixed Mode I/Mode II fracture toughness of polymer matrix composite laminates.

The specimen geometry used in the sandwich MMB test is the same as that specified in the Mode I sandwich SCB test method. The sandwich specimen contains a pre-existing disbond at the upper facesheet/core interface at one end of the specimen. The sandwich MMB test fixture, shown in Fig. 3, is a scaled-up version of the MMB test fixture used with composite laminates in ASTM D6671. This test method enables the determination of mixed-mode fracture toughness values for both crack initiation and propagation. An important feature of the test fixture is the ability to perform tests over a range of Mode I to Mode II ratios.

Sandwich MMB testing consists of subjecting the composite sandwich specimen to three-point flexure loading using rollers that bear against the specimen. Additionally, loading hinges are bonded to both the upper and lower facesheet of the sandwich specimen at the end containing the disbond as shown in Fig. 3. Varying ratios of Mode I-to-Mode II loading are applied to the facesheet disbond by adjusting the horizontal position of the translating loading saddle. Pure Mode II loading is produced when the loading saddle is positioned directly over the central loading roller, resulting in three-point flexure loading. Increasing ratios of Mode I-to-Mode II loading are obtained by moving the loading saddle away from the disbonded end of the specimen, producing an increasing lever arm length that opens the disbonded portion of the sandwich specimen, as in the sandwich SCB test.

Multiple laboratory round-robin testing programs are currently being organized for both the sandwich SCB fatigue and the sandwich MMB test methods. Fabricators of composite sandwich panels, especially those with aluminum honeycomb core, who are able to provide sandwich panels or specimens for use in round-robin testing, are encouraged to contact me at dan@wyomingtestfixtures.com.

Learn more about composites testing by attending Dr. Adams’ 2-day short course “Test Methods for Composite Materials,” Feb. 24-26, 2026, in San Diego, California. Visit for more information or email Dr. Adams.

References

1ASTM D5528/D5528M–21, “Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites,” ASTM International (W. Conshohocken, PA, US), 2022 (first issued in 1994).

2ASTM D6671/D6671M–22, “Standard Test Method for Mixed Mode I-Mode II Interlaminar Fracture Toughness of Unidirectional Fiber Reinforced Polymer Matrix Composites,” ASTM International (W. Conshohocken, PA, US), 2022 (first issued in 2001).

Related Content

Damage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreCrashworthiness testing of composites: A building block approach, Part 1

Determining the crashworthiness of composite structures requires several levels of testing and analysis, starting with coupon-level crush testing.

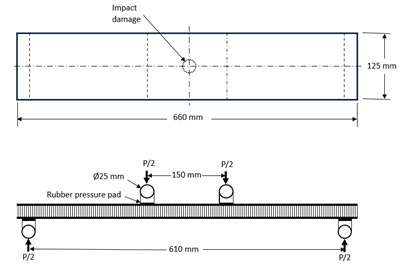

Read MoreDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

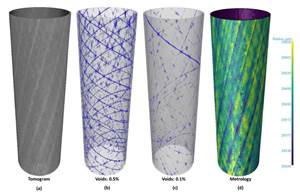

Read MoreMulti-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Read MoreRead Next

Damage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

Read MoreMechanical testing of ceramic matrix composites

Today’s CMC materials, robust and resistant to high temperatures, provide their own set of challenges when determining their performance through mechanical testing.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More