Fraunhofer IGCV develops helicopter door shell using SMV composite

SMC-replacement material subjected to vario-thermal pressing cycle achieved a 1.2-millimeter-thick, complex-shaped door shell, demonstrating feasibility for future aerospace components.

Source (All Images) | Fraunhofer IGCV

’s (Fraunhofer IGCV, Augsburg, Germany) initiative to innovate lightweight, high-performance inner door shells for next-gen helicopters has resulted in the successful development of a thin-walled, complex-shaped composite door shell with a thickness of just 1.2 millimeters.

This development is subsequent to a joint research project between Fraunhofer IGCV and the German Aerospace Center (DLR, Augsburg) called LIGHT that was funded by the Bavarian Ministry of Economic Affairs, Regional Development and Energy. LIGHT involved the helicopter door design and the developed press mold, provided by Airbus Helicopters (Donauwoerth).

The completed door shell mentioned here was developed by Fraunhofer IGCV. The process employs wetlaid nonwoven materials, consisting of a carbon fiber-reinforced thermoplastic fiber-blend, enhanced for optimal performance and drapability. The reinforcement material is further processed using a vario-thermal pressing cycle carried out at DLR’s Center for Lightweight Production Technology (ZLP) in Augsburg. Together, these advancements demonstrate the feasibility for large-scale industrial application.

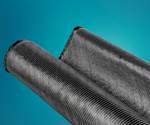

At the heart of the project lies the development of sheet molding veil (SMV), a composite material designed to replace traditional sheet molding compound (SMC). SMV features selectively created fiber agglomerates within a nonwoven base material, replicating the structural benefits of SMC while incorporating recycled fibers for enhanced sustainability.

Completed helicopter door.

The SMV wetlaid nonwoven consists of 12-millimeter-long carbon fibers. It achieves a consolidated ply thickness of 0.2 millimeter with adjustable fiber volume content between 30-42%. According to Fraunhofer IGCV, the lightweight yet robust material ensures optimal performance, including isotropic mechanical properties and improved compatibility with thermoset and thermoplastic matrices.

The SMV material is manufactured using a process that combines precision and efficiency. Preforms made from six layers of nonwoven are subjected to a vario-thermal pressing cycle, which involves heating, pressing and cooling in a custom-designed mold. This process enables the material to conform seamlessly to complex geometries while maintaining uniform quality and high-performance characteristics. The SMV wetlaid nonwoven ensures smooth and consistent shaping during forming, making it an ideal material for intricate aerospace applications like helicopter door components.

Notably, SMV offers a combination of high mechanical performance, sustainability and functional versatility. Use of recycled fibers achieves full recyclability and reduced environmental footprint, while the nonwoven base material provides benefits including noise and vibration insulation, electromagnetic shielding and improved thermal management.

Engineers have further enhanced the material’s adaptability by enabling customization at the material level. Properties such as fiber blends, additives and grammage can be fine-tuned to meet specific application requirements, making SMV a versatile solution for diverse industries.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.