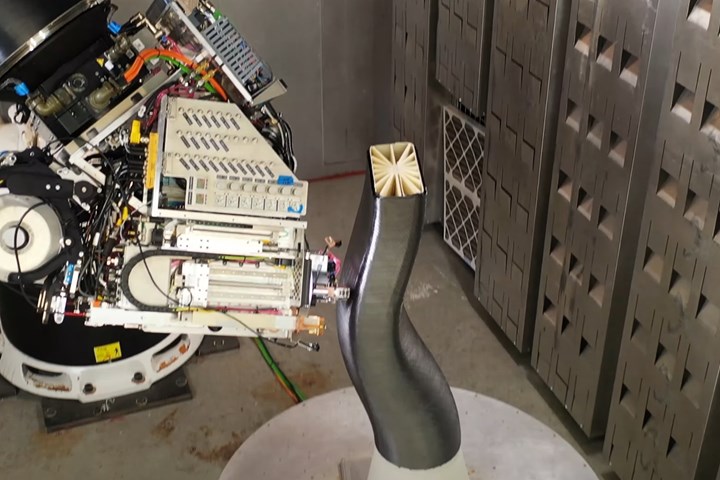

Electroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

Source | Electroimpact

Electroimpact (Mukilteo, Wash., U.S.) has integrated an out-of-autoclave (OOA) in-situ consolidated thermoplastic automated fiber placement (AFP) process and an advanced fused filament fabrication (FFF) 3D printing process into a unified Scalable Composite Robotic Additive Manufacturing (SCRAM) system. SCRAM is a true 6-axis, industrial continuous fiber-reinforced 3D printer, which enables the tool-less rapid fabrication of aerospace-grade integrated composite structures. High-performance thermoplastics combined with a high percentage of continuous fiber reinforcement are used to produce parts with exceptional material properties previously unheard of in the world of additive manufacturing. Electroimpact asserts this technology has no equal in the industry.

“True 3D” printing

Most 3D printing processes are accurately described as “2.5D” printing, because material is deposited successively in flat slices, which are then stacked together to form a 3D object. The SCRAM process, however, can be considered “true 3D” printing because layers of continuous fiber-reinforced thermoplastic can take the shape of complex contours, such as aerodynamic surfaces and ducts for fluid flow. Furthermore, because it is a 6-axis process, fiber orientation within each layer can be tailored to the specific application to provide optimal strength and stiffness distribution throughout the part, much like a conventional AFP system.

Tooling printed on demand

Each SCRAM cell is equipped with not only a reinforced thermoplastic printing system – a scaled-down, more dexterous AFP with in-situ consolidation (ISC) – but also a rapid tool fabrication system based on an advanced FFF printing process. Conventional automated fiber layup requires a substantial investment in hard tooling that is inflexible, expensive and requires long-lead times. In contrast, SCRAM can simply print the support tool on demand, starting from just a flat plate. Later, after the part has finished printing, the tool material is dissolved away, enabling rapid design iterations. It also allows creation of part geometries such as internal channels that are difficult or impossible to produce via conventional means.

Multi-material system

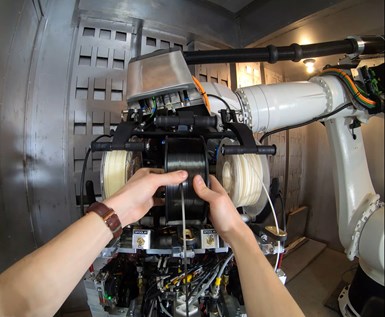

Loading of continuous carbon fiber-reinforced thermoplastic composite tape into Scalable Composite Robotic Additive Manufacturing (SCRAM) system. Source | Electroimpact

In addition to the continuous fiber-reinforced thermoplastic printing process (AFP ISC) and the FFF support tool printing process, SCRAM cells are also fitted with an FFF nozzle optimized for deposition of thermoplastic material reinforced with short or “chopped” fiber. A proprietary laser heating system is incorporated, producing exceptionally strong bonds between layers. This process is ideal for situations where laying up continuous fiber is geometrically impossible or otherwise doesn’t make sense.

Like the continuous fiber process, this is a “true 3D” printing process where the layers are not constrained to a stack of planes. Complex geometries such as variable-density core and other internal structures can be printed directly onto continuous fiber-reinforced layers with widely varying curvature. If desired, continuous fiber-reinforced layers can then be deposited on top of the chopped fiber-reinforced core structure, forming an upper skin. Example materials include:

- PAEK (polyarylketone) family thermoplastics (PEEK, PEKK, etc.)

- Nylons and other low-temp thermoplastics (PA12, ABS, etc.)

- Water-soluble thermoplastics

- Carbon fiber

- Glass fiber

- Boron fiber.

SCRAM cell configuration

Electroimpact’s SCRAM system uses a Siemens 840D CNC controller and 6-axis robot with its patented Accurate Robot package, including a continuous 6th robot axis for utilities pass-through with unlimited rotation. The tool change interface allows end effectors to be picked up and dropped off seamlessly including a multi-material deposition end effector.

The cell includes a heated build platform with rotating hot plate and is housed in a heated build chamber to control thermal expansion and shrinkage. SCRAM also comes standard with a coupon and calibration stand, CAM part programming software suite and training for operators, mechanics, and programmers.

Optional features include:

- High-throughput plastic pellet extrusion end effector, for depositing

large support tools quickly from inexpensive feedstock;

- Subtractive machining end effector, for trimming parts and conditioning support tool surfaces for optimal finish and accuracy;

- Partially reusable support tool system incorporating a water-soluble sacrificial layer for short production runs.

About Electroimpact

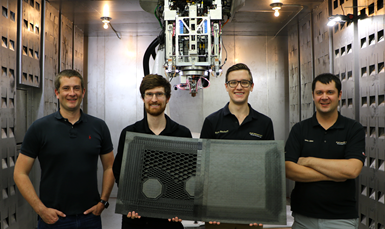

Scalable Composite Robotic Additive Manufacturing (SCRAM) system team includes (left to right) Cody Brown, Jordan Peterson, Ryan Bischoff and Reese Allen. Source | Electroimpact

Electroimpact is an experienced supplier of manufacturing automation and tooling to the aerospace industry. The company is a haven for engineers, who are vertically responsible for all work from concept to customer acceptance with minimal bureaucracy. Their projects include complete automation assembly systems for commercial aircraft wings, AFP (automated fiber placement) systems, high-accuracy robotic drilling and fastening machines, riveting machines for wing panel and fuselage assembly and spacecraft and satellite handling equipment.

Related Content

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreFormula 1 team adopts Roboze 3D printed composites

The Visa Cash App RB Formula 1 team is collaborating with Roboze to reduce weight and create parts with complex geometries via carbon fiber/PEEK.

Read MoreIn oil and gas, an additive manufacturing standard (API 20T) will aid adoption of composites

Polymer AM equipment maker Roboze sees how the oil and gas industry’s way forward with additive is like that of another high-stakes industry, aerospace, and also different in important aspects.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More