Victrex, Daher, attain next-gen thermoplastic aircraft panel milestone

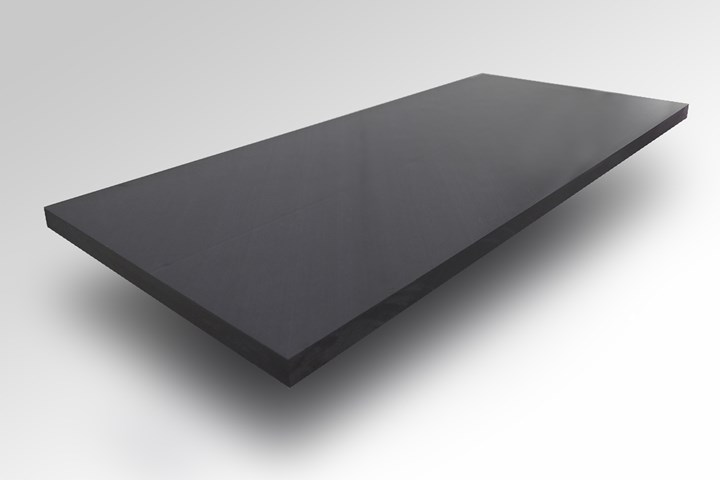

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

Photo Credit: Victrex

It was reported on Oct. 20 that Victrex (Thornton Cleveleys, U.K.) has collaborated with the French aircraft manufacturer and equipment supplier (Wissous, France) to produce a 176-ply laminate structural aircraft panel, with a thickness of 32 millimeters (1.26 inches). The collaboration, notes both companies, results from a need for faster aircraft production. Improving production rates using composite structural components such as panels and brackets, for example, could be the solution.

Using VICTREX AE 250 polyaryletherketone (PAEK)-based thermoplastic composite and an automated fiber placement () processing technique, followed by oven and vacuum or out-of-autoclave (OOA) consolidation, the resulting thermoplastic panel is said to demonstrate that it is possible to achieve aerospace quality laminates with OOA processing in thicknesses not previously attainable. According to Victrex, this may offer key advantages for the global aerospace industry in primary structural applications.

The panel’s dimensions are 120 by 60 centimeters (47 by 24 inches) with a thickness of 32 millimeters (1.3 inches), making it significantly thicker than traditional flat panels, while demonstrating the ability for ply pad-ups and variable thickness with quality acceptable for evaluation and testing. The exceptional thickness of the 176-ply construction is enabled by AFP layup of high-quality unidirectional (UD) thermoplastic tape which requires only consolidation, not autoclave cure. With , says Victrex, consolidation using heated tooling could also significantly reduce production time.

The new panel meets aerospace industry standards for porosity, crystallinity, consolidation and ply bonding.

“The new composite panel meets aerospace industry standards for porosity, crystallinity, consolidation and ply bonding materials are key to the aerospace industry’s future. In addition to reducing weight, fuel consumption and operating costs, they enable faster production rates and are much better for the environment,” says Dominique Bailly, Daher’s vice president of Research and Development. “As the aviation industry foresees the need for more than 40,000 new aircraft during the next 20 years, production simply must accelerate if this level of demand is to be fulfilled.”

Specifically, the panel's engineering specifications include little to no porosity, at less than 1% and crystallinity is rated at 25-30%. According to Victrex, as would be expected of a 176-ply laminate structure, bonding between the composite layers is targeted to achieve the necessary interlaminar shear strength (ILSS), clearly delineating the very high mechanical strength of the panel, where voids are eliminated by the AFP process and high quality and mechanical integrity maintained.

In addition, VICTREX AE 250 UDT can be processed at 280°C (536°F) followed by an oven cycle. It has a relatively low melting point at 305°C (517°F) rather than the 345°C (653°F) of PEEK, a well-known high performance polymer in the PAEK family. This is a distinct advantage in automated thermoplastic processing, says the company, speeding the bonding process and driving up the overall efficiency of aircraft production.

Additional compelling material advantages include up to 5 times higher specific strength and specific stiffness, and up to 4 times higher fatigue resistance, compared to those of metals. Corrosion resistance, processing and thermal insulation are also improved, while impact and chemical resistance as well as damage tolerance will be similar to those of metals. Further, in contrast to thermoset solutions, PAEK composites are fully recyclable, with up to 10 times better damage tolerance, while offering greater chemical resistance, fatigue performance and FST (flame/smoke/toxicity) properties, and still matching strength and stiffness of thermosets.

The key features of the VICTREX AE 250 composites also include outstanding high temperature performance and thermal stability, a wide ranging chemical resistance to aerospace fluids and gases and excellent resistance to hydrolysis and corrosion.

"What we see here is our tape's lightweight properties and the fast AFP process, developed by Coriolis Composites [Queven, France], delivering all the exciting possibilities of metal replacement with thermoplastic composites on a far-reaching scale in aircraft design. At the same time this can also contribute to cutting production backlogs, which now plague aircraft construction as a result of drawn-out assembly schedules that can be anywhere from seven, eight or nine years," comments Tim Herr, director of Aerospace at Victrex. "Working on this pioneering project has been productive and exciting, and we're confident it will help shape, literally, the aircraft and aircraft industry of the future."

Related Content

Flyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

Read MorePrepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Read MoreSyensqo, Teijin Carbon achieve aerospace qualification for composite resin

Resin infusion system Prism EP2400 achieves NCAMP qualification with Teijin Carbon’s advanced NCF and UD reinforcements.

Read MoreAM method enables tool-free, energy-efficient thermoset composites production

University researchers highlight how the combination of a thermally curable resin system with photothermal curing eliminates the post-curing steps involved in discontinuous, continuous fiber parts fabrication.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More