Teijin Carbon Europe launches carbon fiber/PPS UD tape

The new Tenax prepregged tape with PPS matrix allows entry into new cost-sensitive markets while offering the typical TPUD advantages like resistance to chemicals and solvents, low flammability, storage or shipping at room temperature and recyclability.

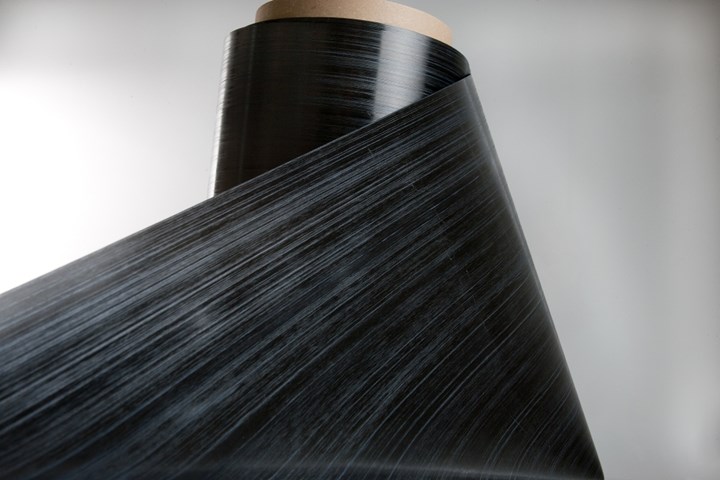

Teijin’s new Tenax carbon fiber/PPS UD tape product. Photo Credit: Teijin Carbon Europe

Teijin Carbon Europe (Wuppertal, Germany) announced on May 19 a new carbon fiber thermoplastic unidirectional pre-impregnated tape (TPUD) based on polyphenylene sulfide (PPS). Teijin says the new Tenax TPUD with PPS matrix allows entry into new cost-sensitive markets while offering the typical TPUD advantages like resistance to chemicals and solvents, low flammability, storage or shipping at room temperature and recyclability.

Due to its flame-retardant properties and low smoke emission, this new Tenax tape can be used in interior applications of aircraft or rail vehicles, among other applications. The maximum continuous operating temperature is up to 220°C. Features of the material include very low water absorption, good creep resistance at elevated temperatures and high dimensional stability. Teijin says these properties make the product suitable for use with automated tape laying (ATL) or automated fiber placement (AFP) in combination with overmolding for complex geometries. Teijin also notes that PPS allows a lower process temperature compared to polyetheretherketone (PEEK) or polyaryletherketone (PAEK). Teijin Tenax TPUD tapes, regardless of resin matrix, are available in a variety of fiber basis weights between 100 and 190 g/m2 on roll lengths up to 2,000 m and in widths up to 24”.

Related Content

-

Bio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.