Processes

CompPair adapts HealTech composites to LCM processes

The new system, demonstrated through the manufacture of a large-scale wind turbine blade section, enables the repair and recovery of infused composite structures within minutes.

Read MoreWindform LX 3.0 composites contribute to OreSat0 CubeSat deployment

Portland State Aerospace Society, incorporating CRP Technology’s GFRP composite materials and SLS 3D printing, sent its CubeSat nanosatellite into low Earth orbit in 2021, where it continues to operate successfully.

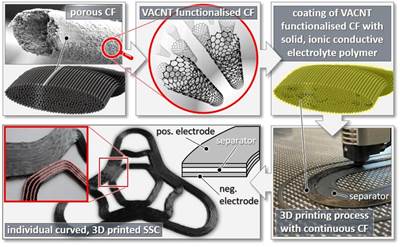

Read MoreRCCF of TU Dresden develops next-gen, 3D-printed structural supercapacitors

Thales Research and Technology leads PRINTCAP project for more sustainable fast-charging, structural energy storage for automotive and aerospace industries using multifunctional composite materials

Read MoreC.R. Onsrud breaks ground for machine shop expansion

Multi-phase expansion includes 9,900-square-foot addition to facility and purchase of new equipment to better serve aerospace, marine, composites and other industries.

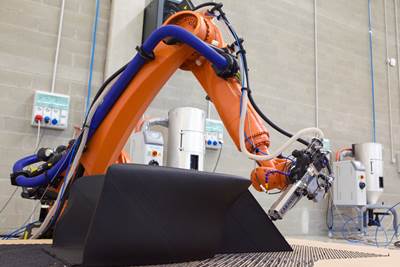

Read MoreCaracol scales up, expands internationally with €10.6 million Series A funding

Development and commercialization of Caracol’s turnkey large-format 3D printing platform Heron AM, and new hubs in North America and Middle East solidify the company’s swift growth.

Read MoreEUVAM project investigates energy-efficient UV process for composites curing

University of Stuttgart researchers intend to develop flexible, highly productive and digitally controllable manufacturing approach for small urban vehicle production.

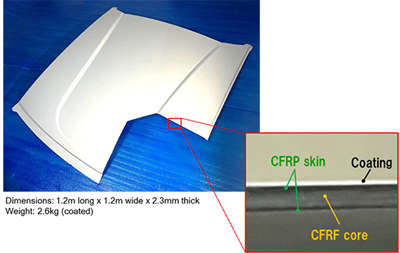

Read MoreToray develops rapid integrated press molding technology for CFRP mobility components

The process and material innovation simultaneously shapes, molds, thermosets and bonds the core and skin in the same mold, achieving this 10 times faster than conventional autoclave molding setups.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreHaydale graphene contributes to stronger, lighter sea kayaks

Bespoke mechanical graphene masterbatch was effectively used in a resin infusion process to increase the strength, stiffness and breakage resistance of Norse Kayaks’ products.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read More