Processes

Novel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MoreCreative Composites Group introduces H-5 rated FRP bridge decking

High-strength pultruded SuperDeck Lite gives ambulances and maintenance vehicles access to trails, bridges, boardwalks and sidewalks

Read MoreU.S. DOE announces $30 million wind turbine materials, manufacturing funding opportunity

Funding opportunity seeks to increase cost efficiency of wind power generation through R&D projects for lightweight composite materials, streamlined 3D printing processes.

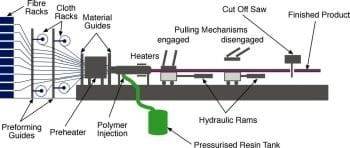

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreDLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

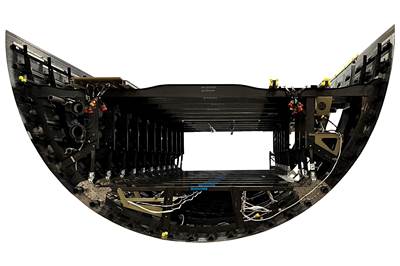

Read MoreSTUNNING project completes lower half of MFFD

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

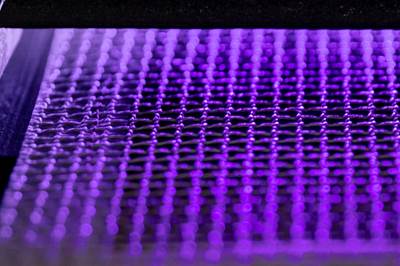

Read MoreArkema, CNRS open France-based lab for UV-curable material exploration

Accelerated photopolymerization research to benefit adhesives, 3D printing, composites, electronics and coatings applications, among others.

Read MoreTNL Applied Composites Manufacturing course begins February 2023

Hybrid, seven-session class helps participants learn the tricks of different composites manufacturing technologies from wet layup to pultrusion.

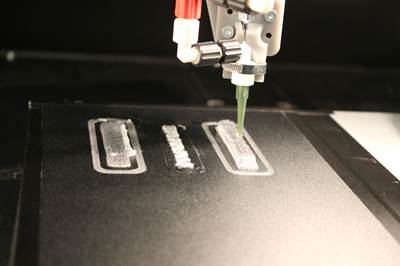

Read MoreNovel 3D printing process achieves development of bio-based composite components

Modeling nature’s material processing techniques, research at DITF and Arburg has enabled the printing of cellulose continuous fibers reinforced with a cellulose matrix at ambient temperatures.

Read MoreKent Pultrusion expands manufacturing facility to address the growing composite market

Doubled capacity increases the fabrication, machining and assembly capabilities for Kent’s servo motor-controlled ServoPul pultrusion lines.

Read More