Processes

Metal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

Read MoreInnoptus Solar Team select JetCam for 2023 World Solar Challenge vehicle fabrication

JetCam software streamlines nesting performance for composite ply assembly and cutting for the team’s 100th solar vehicle.

Read MoreChantiers de l’Atlantique reveals 66-meter, all-composite SolidSail mast

A technological feat, the large carbon fiber mast prototype targets the Silenseas sailing liner and sailing cargo ships for up to 40% reduction in CO2 emissions.

Read MoreINN-PAEK project to develop 100% recyclable, lightweight thermoplastic flange wheels for future aircraft

The AITIIP Technology Center leads this research with partner Liebherr Group to develop a technology by June 2023 that contributes to more sustainable, eco-friendly production systems.

Read MoreEastman Machine automated cutting equipment increases HanseYacht efficiencies by 85%

Since implementation of its first conveyorized cutting system, the recreational boatbuilder regularly seeks ways to improve its composite material handling processes.

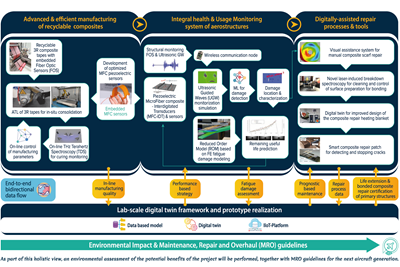

Read MoreEU-funded GENEX project to develop digital twin framework for aircraft lifecycle tracking

Novel digital framework to enable holistic and comprehensive data capture through the entire aircraft lifecycle, supporting composite component/structure manufacture optimization and maintenance.

Read MoreFrom plant tours to EV battery enclosures: The top 10 ÂÌñÏ×ÆÞ articles of 2022

Through a variety of editorial content, CW explored the trends and topics that are rapidly flourishing in the industry. Based on Google Analytics, these top 10 articles were considered the most popular.

Read MoreNorco to build fuselage, wings and composite components for Skyfly eVTOL aircraft

Skyfly aims to achieve a complete airframe weight of just 220 kilograms, in addition to low-cost, accurate and reliable repeatability of manufacture for series production progression.

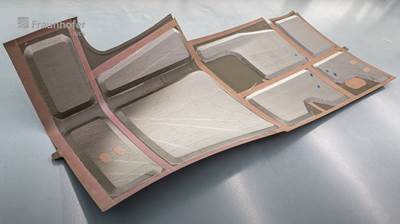

WatchOptimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

WatchCryomotive opens Hydrogen Storage Manufacturing Center

Cryomotive is to develop, manufacture and assemble Cryogas composite hydrogen tanks for commercial vehicles, buses and ships at new Pfeffenhausen site, accelerating hydrogen refueling systems production for zero-emission commercial vehicles.

Read More