Weaving

SMC sandwich panels: Lean process opens doors

Patented process enables compression molding at lower pressures, saving capital equipment costs for panel fabrication.

Read MoreSAMPE Tech 2011 in Texas

The Society’s annual fall gathering fills an exhibition hall this year nearly as big as the host state.

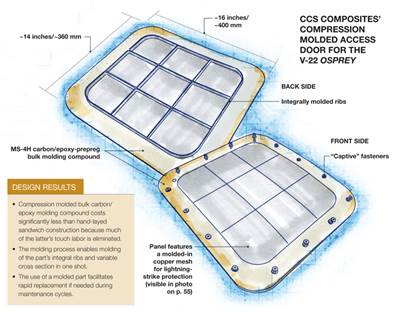

Read MoreRedesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

Read MoreSpread-tow fabric secures ultralight aircraft’s weight goal

Shark Aero (Hlboké, Slovak Republic) designed its composite-airframed, single-seat prototype ultralight aircraft (ULA), the Shark UL, with spread-tow carbon fiber woven fabrics to reduce weight.

Read MoreSea and land transport: Hydro elevation

Composites lightweight and toughen the hull and superstructure of this transplanted amphibious naval hovercraft.

Read MoreCarbon fiber composites: The past can be the future

JIm Stike, of Materials Innovation Technologies – Reengineered Carbon Fibers (Fletcher, N.C.), points to progress in the reclaiming of waste and end-of-life carbon fiber.

Read MoreComparison of shear-loaded compression test fixtures

Dr. Donald F. Adams compares the three basic types of shear-loaded compression test fixtures.

Read MoreTriaxial fabric wrap saves critical highway pier

The Department of Civil Engineering at the University of Kentucky (Lexington, Ky.), and sister research group the Kentucky Transportation Cabinet, recently completed the first bridge pier repair demonstration project to use triaxial carbon fabric.

Read MoreDesigning the largest solar-powered vacht

All-composite catamaran Tûranor continues its global circumnavigation, using only the power of the sun.

Read MoreSelf-deployable, composite satellite boom

Researchers design and validate a boom made of ultrathin carbon-fiber/epoxy laminate, using a novel, highly accurate analysis method.

Read More