Weaving

Tabbing composite test specimens: The how

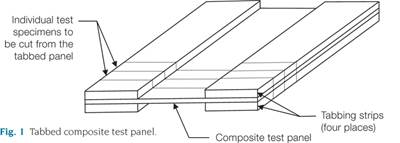

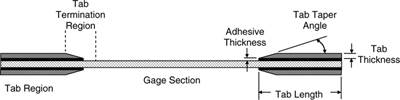

The when and why of tabbing composite test specimens were the subjects of my previous column (see “Tabbng composite test specimens: When and why," under "Editor's Picks," at right), which included a discussion of tabbing materials, tab thickness and taper angle, and adhesive selection.

Read MoreJEC Paris 2011 highlights

The news from this annual Parisian in-gathering of composites professionals is heavily weighted toward automotive lightweighting.

Read MoreSoftware eases design/build for exotic exercise bike

The Lamiflex Group (Bergamo, Italy) helps Milan, Italy-based design house Luca Schieppati develop the Ciclotte, a striking luxury exercise bicycle made with carbon fiber composites.

Read MoreNanotechnology: Into the realm of real

Fast, scalable process grows nanostructures directly on composite reinforcements for a “drop-in” use in volume production processes.

Read More3-D woven reinforcements update

Suppliers make progress toward reinforcement preforms that exhibit comparable properties in the x, y and z axes.

Read MoreTabbing composite test specimens: When and why

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses when and why test specimens must be protected by tabs.

Read MoreMae West: Pipe dream in Munich

Unique fiber architecture and mandrel-less filament winding process make “impossible” rotational paraboloid sculpture possible in carbon composites.

Read MorePortable wind turbine powers the warrior

DARPA-financed program puts wind energy to use for battery and system recharging.

Read MoreAntiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read More