Weaving

Building a better corrosion-control composite

Many FRP products used in corrosive environments — pipe, tanks, ductwork, stack liners and so forth — are constructed with filament winding or pultrusion processes and contain 60 to 70 percent glass fiber reinforcement by weight.

Read MoreIndustrial corrosion control: Huge opportunities

Fiber-reinforced plastic is the ideal but still widely ignored option in environments that eat away at most metal alloys. Opportunities abound, but the key is still education.

Read MoreOff-grid turbine: Helix in the wind

This new composite twist on the vertical-axis wind turbine makes no small impact on the private power market.

Read MoreMilking platforms: Composites transform New Zealand cow sheds

Waikato Milking Systems (Hamilton, New Zealand) introduced its Centrus composite milking platform in 2009 and, since then, has installed 24 platforms at customer sites. They're made via RTM Lite.

Read MoreRapid layup: New 3-D preform technology

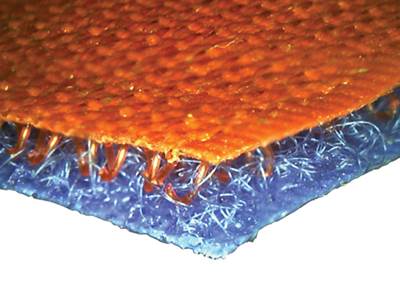

Hook-and-loop fasteners speed layup of carbon, aramid, glass and hybrid fabrics while improving composites’ mechanical performance.

Read MoreSixth Element: Lamborghini accelerates CFRP

The automaker’s R&D centers in Italy and the U.S. implement aerospace-inspired design philosophy to radically enhance the use — and the benefits — of CFRP.

Read More2012 Farnborough International Airshow Report

The biennial U.K. air event delivered the clear message that the aerospace industry — and aerospace composites with it — continue to soar.

Read MoreAuto composites quest: One-minute cycle time?

Faced with high fuel prices and ever-more stringent restrictions on tailpipe emissions, automakers are taking composites into their own hands.

Read MoreComposites as costume: Manga masterpieces

Sophisticated design meets composite materials and manufacturing in cosplay application.

Read MoreInfused CFRP: New One-Design paradigm

The Farr 400 opens a new frontier in Grand Prix sail racing, with greater precision at lower cost.

Read More