Design & Tooling

Quiet supersonic demonstrator X-59 begins ground testing in Texas

Critical testing ensure the composite aircraft can withstand the loads and stresses that typically occur during supersonic flight.

Read MoreMS-21-300 debuts first flight with carbon fiber wing

Certification of the MS-21-300 aircraft is nearing completion, with plans to start delivering it to customers in 2022.

Read MoreExpleo extends engineered services agreement with Spirit AeroSystems

The global engineering, technology and consulting service provider leverages expertise in composites, stress and design and advanced automation and AI to shape novel emerging aerospace technologies.

Read MoreNCC sensor technology unlocks digital potential for liquid resin processes

Research and testing of dielectric sensors performed by the NCC, Meggitt and Cranfield University accurately captures resin infusion data, shows promise for composites manufacturing.

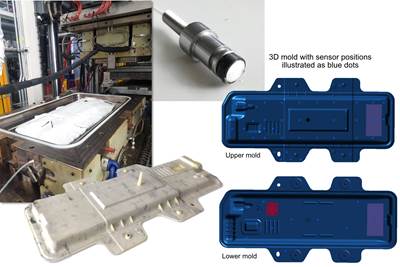

Read MoreCustomizing ultrasonic sensors for composites process optimization and control

University of Augsburg developed sensors for the CosiMo project’s digital twin and closed-loop process control of EV battery box cover demonstrator, and now moves forward with the AI Production Network for industry collaboration.

Read MoreRuckus Composites launches composite bicycle science program, identifies upcoming research

The program, which has currently analyzed the carbon fiber frame repair footprint, ultrasonic testing and surface preparation, will extensively study sustainability, design, maintenance and repair.

Read MorePlant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

Read MoreMT Aerospace proves out CFRP hydrogen tank for rocket propulsion

Comprehensive test campaign under the ESA’s ComET project proves linerless composite pressure tank prototype can withstand cryogenic stresses inherent to rocket flight.

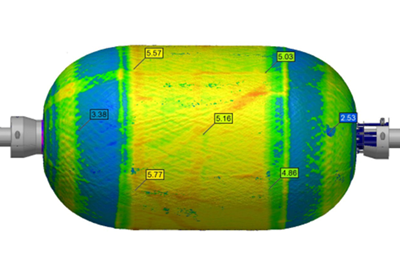

Read MoreNCC’s all-composite Type V tank demonstrates future composite space tank technology

SpaceTank project delivers a 96-liter carbon fiber composite tank with 4.0-5.50-millimeter nominal wall thickness for 30% weight savings in launch vehicle and satellite propellant tank applications.

Read MoreAutonomous, electric shuttle retrofitted with CRP Technology Windform materials

Advanced 3D printing production process and Windform composite materials used to manufacture the required motor cover and washer reservoir flap valve components, account for Olli 2.0’s pod-like shape.

Read More