Ruckus Composites launches composite bicycle science program, identifies upcoming research

The program, which has currently analyzed the carbon fiber frame repair footprint, ultrasonic testing and surface preparation, will extensively study sustainability, design, maintenance and repair.

Adhesion testing. Photo Credit, all images: Ruckus Composites

(Portland, Ore., U.S.) focuses continuously on setting the standard for the inspection and repair of carbon fiber bicycles; so far, more than 16,000 bicycles have been studied. Recently, the company launched a cutting-edge carbon bicycle science program that uses chemistry, physics and engineering to investigate important questions in fields including sustainability, design, maintenance and repair. This program is designed to provide information for scientists, bicycle technicians and consumers.

Highlights of the program thus far include:

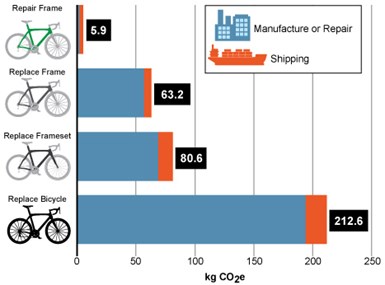

Composite bicycle repair carbon footprint.

- at Ruckus Composites showing that repair produces up to 95% fewer greenhouse-equivalent gas emissions than replacement.

- Publication of a and presentation, “Ultrasonic Testing of Carbon Fiber Bicycles,” at the International Ultrasonics Testing Online Conference 2021. This paper/video ranked in the top ten most-viewed at the conference.

- to determine the best methodology for surface preparation of carbon fiber composite for bonding with substances such as adhesives and paint. Proper surface preparation is vital for safe repairs, says the company.

Frame top tube failure.

Ruckus Composites also identifies some additional topics in the pipeline in 2022 which include:

- Drop impact testing of carbon fiber frames. This is a tool drop study to determine if any damages can occur from dropped tools.

- Galvanic corrosion, where the company is even creating a “sweat bath” for certain components.

- Exploration of epoxy and carbon fiber to gain general knowledge on material.

- Torque in the context of bicycle repair. According to Ruckus Composites, it will be using a calibrated, highly accurate (0.2%), low-range digital torque wrench to squeeze and crack tubes with precision.

Related Content

-

Watch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

-

Composites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

-

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.