Design & Tooling

Airbus C295 technology demonstrator makes maiden flight, proves novel design, manufacturing processes

C295 Flight Test Bed 2 (FTB2) tests OOA composite semi-morphing wing, flaps and flap tabs, as well as SatCom antenna for future turboprop aircraft.

Read MoreHybrid battery cover: Materials, process decisions

A Q&A with Timo Huber, vice president of HRC’s Advanced Composite Technology Center, discusses material and process considerations for HRC Group’s SMC electric vehicle battery cover research project.

Read MoreCFRTP E-bike frames enable repair and end-of-life repurposing

Under its Novel Composites E-Bike project, the NCC, with Starling Cycles and Composite Braiding, proved the use of thermoplastics for the production of electric mountain bicycle frames.

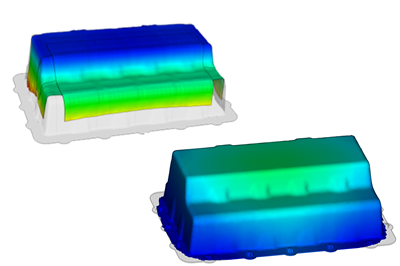

Read MoreHybrid battery cover: CAE approach

A Q&A with Benedikt Fengler, co-founder and composites simulation specialist for Simutence provides a more in-depth take on moldfilling, warpage and assembly simulations performed in HRC Group’s SMC battery cover feasibility study.

Read MoreInstron introduces 3400 and 6800 Series universal testing systems

New high-force floor models range up to 300-kilonewton force capacity, with a host of new features covering user safety, comfort, repeatability and long-lasting service life.

Read MoreExternal, internal mold release systems

Acmos Inc. has published a product brochure that outlines the types and capabilities of mold release systems offered by the company.

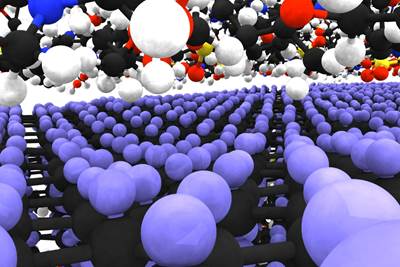

Read MoreNASA Institute develops carbon nanotube-based composites for Mars spacecraft

The five-year project employs computational modeling techniques to build composite panels that are three times stiffer and stronger than current carbon fiber to enable manned missions to Mars.

Read MoreGKN Aerospace named supplier of all Gulfstream G800, G400 business jets

Workshare includes design and manufacture of sustainable, thermoplastic composite rudder, elevators and floorboards, as well as metal-bonded fuselage panels and machined wing skins.

Read MoreDNV lowers the partial reduction factor γm1 of wind turbine blades using aging-resistant PU

The adjustment certification, which gives lower safety margins to polyurethane (PU) resin used in rotor blades, marks broader blade design and applications for Covestro.

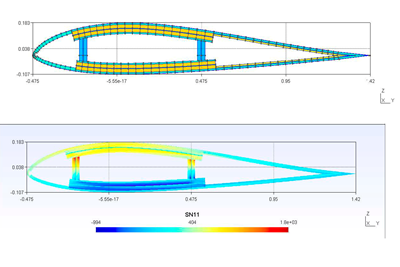

Read MoreAnalySwift improves simulation of composite helicopter, air mobility blades and other slender structures

VABS 4.0 now enables users to evaluate cross section strength and safety under given loads.

Read More