.jpg;maxWidth=250;quality=70)

Hannah Mason Technical Editor

Multi-material toolbox for cost-effective, scalable EV battery enclosure design

Mexico-based automotive Tier 1 Katcon has developed a “toolbox” of material, process and joining options aiming to serve a range of electric vehicle requirements.

Read MoreLifting arm concept and automated repair training to propel portable repair system

Looking to commercialize its Portable Scarfing/Composite Repair System concept, AGFM and partners offer specialized training, lifting and inspection systems.

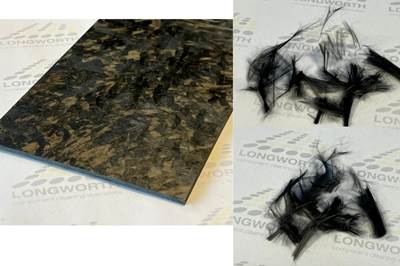

Read MorePressurized steam-based composites recycling for full fiber reclamation

Longworth’s DEECOM process for composites recycling claims to produce intact fiber and resin reclamation with near-virgin properties.

WatchSNO-GO ski bikes increase performance, reduce weight with carbon fiber components

Engineered with articulated rear skis for more control and accessibility, SNO-GO’s new hexagon-shaped carbon fiber components reduce weight and increase performance.

WatchPultruded fiberglass rods enhance athletic training device

Jump Sticks, developed by Flexi-StiX LLC, combine pultruded fiberglass rods within a PVC tube to produce a semi-flexible but resistant training device for enhanced dynamic athletic training.

Read MoreProtocol aims to improve testing of thermal runaway for composite EV battery enclosures

Hyundai-Kia and Forward Engineering developed a resistive, heater-based material test, recently published as a UL standard, to aid and speed composite battery enclosure development.

Read MoreEnvisioning high-volume, 100% composite wheels

Vision Wheel debuted its first carbon fiber composite wheel at CAMX 2021, claiming its low-cost, high-volume process can be scaled up for performance vehicles, UTVs and — ultimately — passenger EVs.

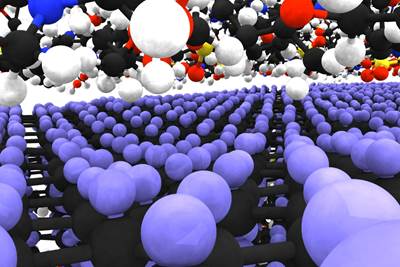

Read MoreNASA Institute develops carbon nanotube-based composites for Mars spacecraft

The five-year project employs computational modeling techniques to build composite panels that are three times stiffer and stronger than current carbon fiber to enable manned missions to Mars.

Read MoreUniversity of Iceland develops process for manufacturing one-piece racecar airfoils

Called the “Spark” method and based on a method for producing CFRP prosthetics, this single-mold, adhesive-free process is said to show potential for a variety of applications.

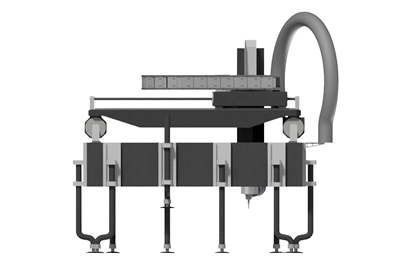

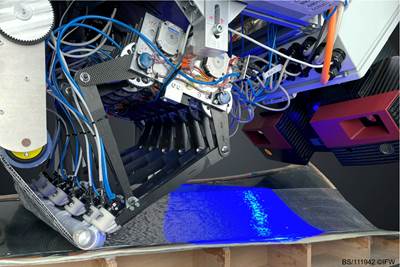

Read MoreModular draping system shows potential for wrinkle-free, automated dry fiber layup

Through research programs FlexProCFK and AutoBLADE, Leibniz University and partners are developing a robot-mounted layup system for complex CFRP parts.

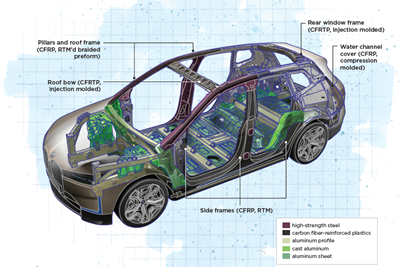

Read MoreBMW rolls out multi-material Carbon Cage with 2022 iX vehicle line

For its new battery-electric iX sports activity vehicle, BMW combines CFRP strategies from previous i3, i8 and 7-Series designs and adds CFRTP for a lightweight, rigid frame.

WatchCustomized resin flow mesh products save time, cost for wind turbine blade manufacturers

As longer composite wind blades are developed, customized mesh products help OEMs and kitting companies control resin flow and remove air voids during infusion.

Read More