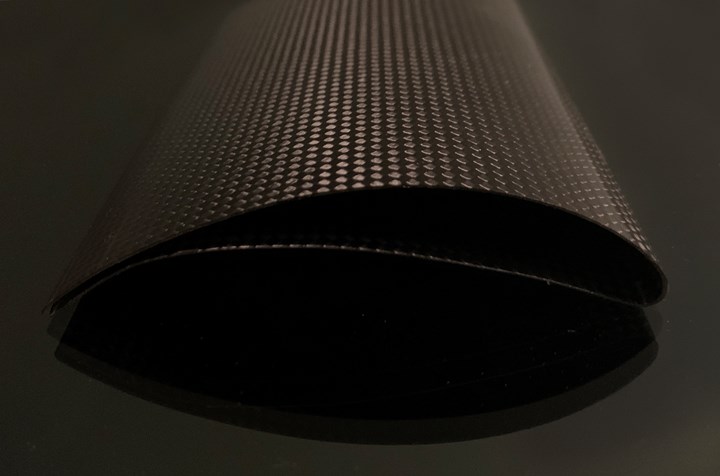

Student members of the University of Iceland’s Formula Student Team, Team Spark, worked with sponsor company Össur to develop a better airfoil/wing that is one seamless piece requiring only one mold and no post-processing. Photo Credit, all images: Technology Transfer Office Iceland

Airfoils, also called wings, are a staple aerodynamic component on racecars, including those developed for university engineering and racing competitions like Formula Student (in Europe) and Formula SAE (in the U.S.). These components, often made from composite materials, are designed to control airflow around the back of the vehicle, with the goal of enabling the highest speeds possible.

Typically, the manufacturing process includes the design and build of two molds, hand layup and cure of the airfoil in two pieces and then adhesive bonding to join the parts together into one component. However, former (Reykjavik) Formula Student team members Sólrún Traustadóttir and Andri Orrason recognized a number of issues using this traditional method. For a sponsor-funded student team, the development of two separate molds for one part could be prohibitively expensive. In addition, the adhesive used to bond the trailing and leading edges of the two airfoil pieces added weight to a part that is meant by design to be lightweight and aerodynamic, and was weaker at the joint. “These things caused us to look for alternative solutions and we ended up with the Spark design,” Traustadóttir and Orrason say.

In 2016, Traustadóttir and Orrason led the development of a new method for producing a one-piece airfoil — a method that the team still uses today. For its method, the University of Iceland’s Formula Student team — named — drew inspiration from and worked with one of its sponsors, (Reykjavik, Iceland), a company that makes carbon fiber-reinforced plastic (CFRP) medical prosthetics.

The student researchers patented their process in 2019 and aim to extend “the Spark method” to production of parts for other markets or applications as well.

A typical process would first involve designing and building two negative/female molds for fabricating the two airfoil halves. In the new process, one positive/male mold is built in the shape of the entire airfoil part. The mold is then covered by an adhesive layer, followed by hand layup of carbon fiber prepreg. Additional material layers such as Teflon or silicone can also be used. The entire set-up is then vacuum bagged and cured via autoclave. Once cured and demolded, no further post-processing or assembly steps are needed.The process saves time both by the use of only one mold and the elimination of bonding/post-processing steps.

The resulting one-piece, seamless airfoil/wing and its manufacturing method are said to have caught the attention of other Formula Student teams as well as Formula 1. Traustadóttir and Orrason note that this method can be adjusted to a variety of materials and processes, as well — including less expensive alternatives to prepreg and autoclave cure.

The technology, , is said to have achieved technology readiness level (TRL) 7. Through the (Reykjavik) Traustadóttir and Orrason are open to licensing opportunities with commercial partners. The Spark team hopes to translate this technology into commercial applications in a variety of end markets, seeing potential for industries such as wind, drones, space, aerospace, automotive and more.

For more information and licensing opportunities, please contact susan@ttoiceland.is at Technology Transfer Office Iceland.

Related Content

Bucci Composites expands automotive production capabilities with facility addition, new high-ton presses

CW Top Shops recipient Bucci Composites shares an update on its facility expansion, automotive composites applications, sustainability, education initiatives and more.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreDaher inaugurates Learning Center for training aeronautical talent

Daher offers a concrete solution to the shortage of qualified professionals in aerospace, providing a range of technical programs that prepare workers for the sector’s rigorous demands.

Read MoreWinona State, IACMI invest in composites workforce development

First composites hub in the IACMI-managed ACE national training program funds free bootcamps to equip students and community with hands-on composites skills, knowledge.

Read MoreRead Next

3D printing, composite materials enable motorsports design flexibility

A collegiate Formula SAE racing team used Windform carbon fiber-filled composite materials and laser sintering technology to streamline part design.

Read MoreRacing to build tomorrow’s automotive composites workforce

Recent graduates share experiences gained from collegiate automotive design, engineering and motorsport competition Formula SAE.

Read MoreItalian student design team uses composites to improve automotive performance

Politecnico di Milano’s Formula SAE team worked with Exel Composites to transition to lighter, better-performing composite vehicle components.

Read More

.jpg;width=70;height=70;mode=crop)