Work In Progress

Fusing waterjet, laser for efficiency in CFRP/CMC machining

Laser MicroJet technology offers high accuracy and speed without heat issues, burring or replacement of cutting tools.

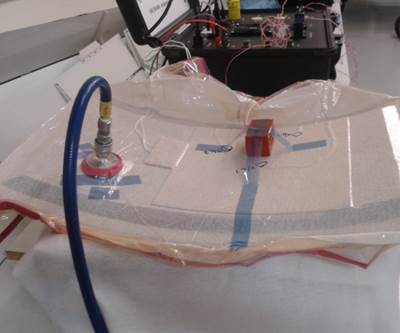

Read MoreReusable vacuum bags go digital

CAD-guided casting boosts precision, utility of reusable vacuum bags.

Read MoreZero-waste: New process, equipment recycles prepreg, tape offal

Technology provides sustainable approach to reusing valuable thermoplastic scrap in chips-based laminate.

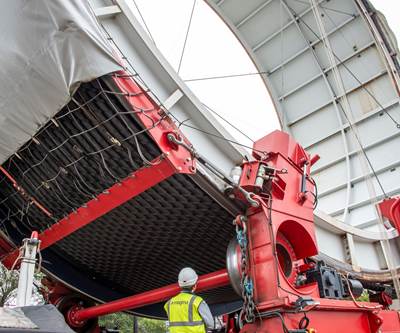

WatchProving viability of dry fabrics, infusion for large aerostructures

Danobat’s ADMP is used to produce a wing demonstrator with non-crimp fabrics.

Read MoreThermoplastic composite pipe on the rise in the deep sea

Demonstrators, pilot programs and qualification efforts are paying off as thermoplastic composite pipe (TCP) makers take orders for deep-sea oil and gas applications.

Read MoreThermoplastic door a first for automotive composites

A team of automotive researchers are engaged in a four-year project with goals of building a lighter, 100% recyclable, carbon fiber-reinforced thermoplastic door.

Read MoreBio-composites break into structural automotive applications

A company’s bio-based, polyamide composite comes with a unique property profile that may help it carve a niche in automotive applications.

Read MoreDeveloping next-generation composites talent

The M.C. Gill Composites Center at the University of Southern California has steadily grown to become one of the industry’s educational and R&D stalwarts.

WatchMeasuring temperature inside composites and bondlines

ThermoPulse sensors offer Industry 4.0 temperature measurement and digital cure cycle management for bonded composite repairs, laminates and more.

Read MoreA highly-manufacturable, high-performance hang glider

A small Swiss company has developed a fast and easily deployed manufacturing method for producing a competition-worthy rigid hang glider.

Read More