Work In Progress

Riding pretty: Hybrid upper control arms move to pickups

Short-glass/PA6 with metallic inserts reduces mass, running torque, joint wear on the Ram 1500 half-ton pickup truck.

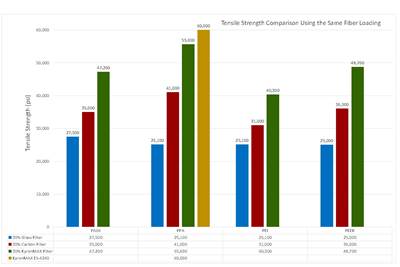

Read MoreShort carbon fiber compounds expand reach of thermoplastic composites

With fiber weight fractions of up to 50% and an array of thermoplastic matrices available, injection molding compounds are expanding composites’ capabilities.

Read MoreThermoplastic tapes continue to show potential for composite aerostructures

Web Industries reports increased R&D activity within several aerospace markets enabled by the flexibility and advantages of thermoplastic tapes.

Read MoreComposite-metal joining, braided preforms enable next-generation aircraft design

Collins Aerospace invests in new joining, preforming and infusion techniques to target aircraft design needs for reduced weight and lower-cost manufacture.

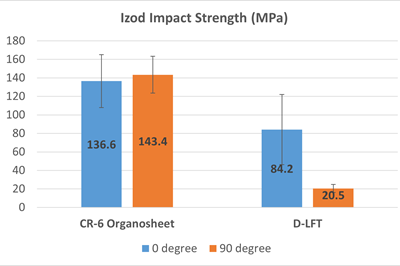

WatchReactively polymerized resin expands organosheet market, opportunities

Johns Manville to introduce Neomera, a new family of thermoplastic composites.

Read MoreLeveraging large-format AM fuels aerospace flexibility

Ascent Aerospace is known for producing high-quality metallic molds and tools for large aerostructures. Investment in large-format AM has expanded the company’s capabilities.

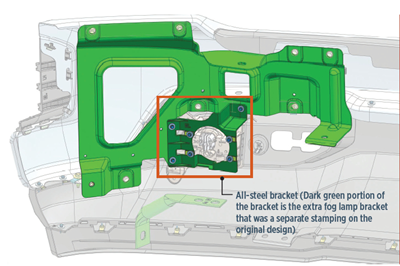

WatchThermoplastic composites: Structural bumper bracket

Hybrid bracket reduces mass, increases design flexibility, package space in pickup front bumper.

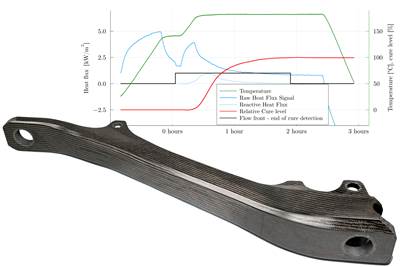

Read MoreSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

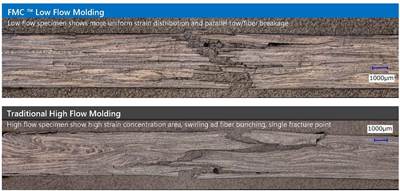

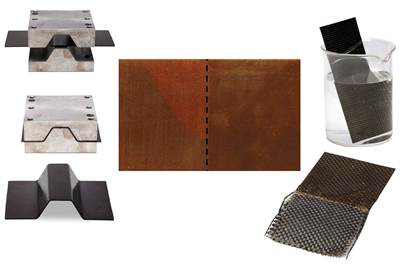

Read MoreForged molding compound: Extending SMC capabilities

New material, design, process combination approaches prepreg performance with chopped carbon fiber SMC.

Read MoreReprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

Watch