Work In Progress

3D printing continuous fiber on the desktop

Additive manufacturing technology company expands offerings to include high-performance composites.

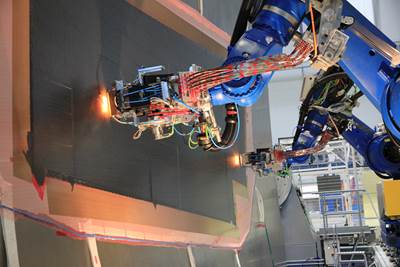

WatchModular, mobile, multiple robotics poised to change the AFP/ATL paradigm

The German Aerospace Center (DLR) is working on two multi-robot automated fiber and tape placement technologies that could change the paradigm in large-part aerocomposites manufacturing.

Read MoreCarbon fiber/epoxy for automotive mass reduction, mass production

IACMI precompetitive research explores carbon fiber-reinforced prepreg, SMC with novel matrix for structural passenger-car applications.

Read MoreRocket module manufactured with in-situ consolidation survives first flight test

A carbon fiber-reinforced thermoplastic (CFRP) module developed at the Technical University of Munich survived its first launch — and a “hard landing” — in March.

Read MoreCompression presses keep evolving in response to composites innovation

Shorter, lighter, smaller footprint Fiberpress machines are ideal for facilities with lower ceilings, automated production lines.

Read MoreInjection-forming for high-performance, unitized thermoplastic structures

Combining braided tape, overmolding and form-locking, herone produces one-piece, high-torque gear-driveshaft as demonstrator for broad range of applications.

Read MoreAcrylonitrile from biomass scales up

Affordable, sustainable, efficient manufacture of biomass-based acrylonitrile — the primary feedstock of carbon fiber production — is leaving the lab and entering the real world.

Read MoreEvolving AFP for the next generation

‘Aerospace quality at automotive pace’ is the mantra of the supply chain being developed for next-generation commercial aircraft. Automation is evolving to meet the challenge.

Read MoreSpirit AeroSystems debuts next-generation composite fuselage panel

The 18-by-12-foot (5.5-by-3.7-meter) demonstrator panel debuted at the Paris Air Show features integrated skin and stringers and offers substantial cost savings combined with strong performance attributes.

Read MoreSplit tow carbon fiber boosts SMC performance

Pre-spread, pre-scored tow band provides better fiber dispersion, wetout, molding properties.

Read More