Work In Progress

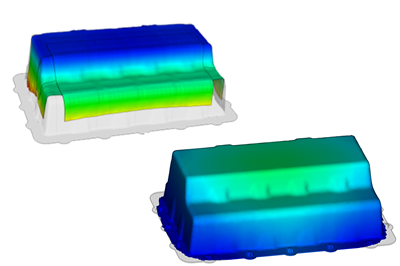

Hybrid battery cover: CAE approach

A Q&A with Benedikt Fengler, co-founder and composites simulation specialist for Simutence provides a more in-depth take on moldfilling, warpage and assembly simulations performed in HRC Group’s SMC battery cover feasibility study.

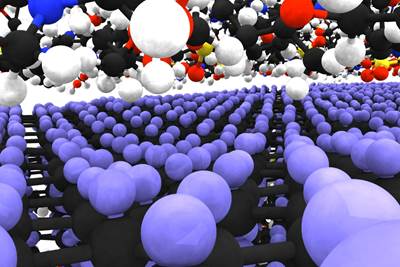

Read MoreNASA Institute develops carbon nanotube-based composites for Mars spacecraft

The five-year project employs computational modeling techniques to build composite panels that are three times stiffer and stronger than current carbon fiber to enable manned missions to Mars.

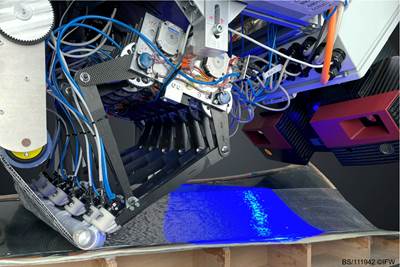

Read MoreModular draping system shows potential for wrinkle-free, automated dry fiber layup

Through research programs FlexProCFK and AutoBLADE, Leibniz University and partners are developing a robot-mounted layup system for complex CFRP parts.

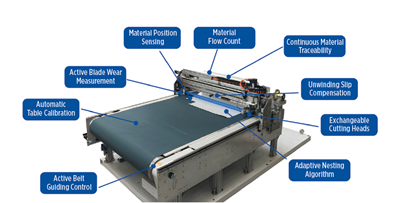

Read MoreModular cutting and stacking system advances flexible, fully automated operations

Integration of next-gen cutting and stacking systems into production lines brings new level of efficiency, quality control.

Read MoreAll-electric motor boat tests the waters for recycled carbon fiber

RS Sailing aimed to create a fully electric, rigid inflatable boat (RIB) that is produced as sustainably as possible. A few iterations later, the Pulse 63 is ready to hit the water.

Read MoreMoving toward portable, digitized composite part repair

Using digital twin technology, American GFM’s portable, automated inspection and scarfing system shows potential for on-site, data-driven composite aircraft part repair.

Read MoreRiding pretty: Hybrid upper control arms move to pickups

Short-glass/PA6 with metallic inserts reduces mass, running torque, joint wear on the Ram 1500 half-ton pickup truck.

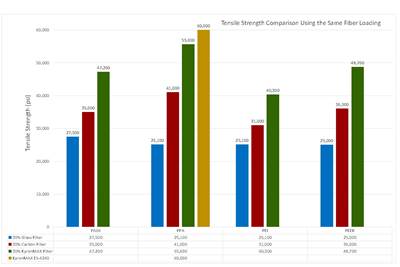

Read MoreShort carbon fiber compounds expand reach of thermoplastic composites

With fiber weight fractions of up to 50% and an array of thermoplastic matrices available, injection molding compounds are expanding composites’ capabilities.

Read MoreThermoplastic tapes continue to show potential for composite aerostructures

Web Industries reports increased R&D activity within several aerospace markets enabled by the flexibility and advantages of thermoplastic tapes.

Read MoreComposite-metal joining, braided preforms enable next-generation aircraft design

Collins Aerospace invests in new joining, preforming and infusion techniques to target aircraft design needs for reduced weight and lower-cost manufacture.

Watch