Work In Progress

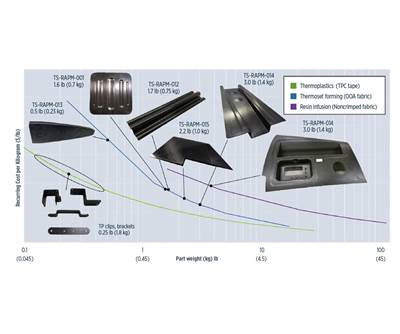

Revolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read MoreCurved pultrusions enter production

Corvette CFRP rear bumper beam is the auto industry’s first use of new technology.

Read MoreThe evolution of composites in NASCAR

The growing role of carbon fiber in stock car racing.

Read MoreRevolutionizing the composites cost paradigm, Part 1: Feedstock

Highly-aligned, short-fiber Tailorable Universal Feedstock for Forming achieves aerospace properties, metal-like formability in zero-waste, fiber-to-parts pilot plant.

WatchGreener camping: Sonic X breaks barriers

Prototype travel trailer generates excitement, leads to new commercial models.

Read MoreAutomation options arise for labor-intensive composites

Typically labor-intensive fabrication processes have more automation options as new technology works in concert with operators to improve efficiency.

Read MoreCFRP preform technology is fast, flexible, efficient

Porsche racecar is first to sport part-via-preform technology.

Read MoreOne-piece, one-cure, infused carbon fiber wheel is ready to roll

ESE Carbon Co.’s new carbon fiber wheel uses tailored fiber placement and custom presses to minimize waste and improve scalability.

WatchOvermolding on the cheap

Innovative injection/compression composites overmolding approach combines smaller injection molded inserts with compression molded parts.

Read MoreAdditive Molding promises mass-produced high-performance composites

Arris Composites introduces a patent-pending technology that manufactures high-performance thermoplastic composite components with a combination of additive manufacturing technology and high-speed compression molding. Has mass production of advanced composite components finally arrived?

Read More