Work In Progress

Streamlining aerospace composites operations with RFID tracking

Tier 1 Sekisui Aerospace’s implementation of RFID tracking, sensors and Xemelgo software at two of its production facilities led to increased productivity, eliminating bottlenecks and reducing labor costs.

WatchCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreUltra-thin woven fabric enables 90% resource reduction in satellite solar array manufacturing

Kerberos Engineering uses TeXtreme 0/90 woven fabrics for satellite solar array manufacturing, cutting weight and onboard resources, enhancing structural integrity and streamlining production.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

WatchLaser-excited acoustics provide contact-free, nondestructive composites inspection

Xarion’s couplant-free NDT technology uses laser physics and a membrane-free optical microphone, eliminating the requirement for fluid coupling, widening the scope for NDT technology.

Read MoreReinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

WatchFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

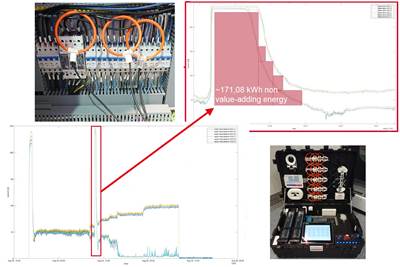

Read MoreMeasuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read More