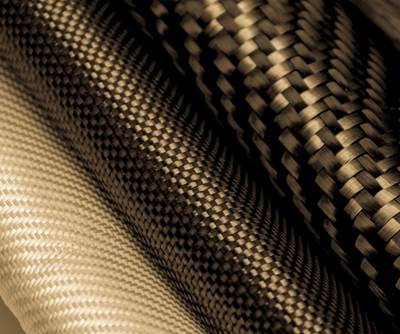

Weaving

PRF Composite Materials announces new unidirectional prepreg line

PRF’s new UD prepreg capability includes carbon materials from 80 to 600gsm, at standard widths of 300 mm and 600 mm.

Read MoreJEC World 2019 preview: Michelman

Michelman (Cincinnati, Ohio, U.S.) is introducing its family of Unyte surface modifiers formulated specifically for manufacturers of technical textiles and prepreg fabrics.

Read MoreCombining materials for better bicycles

Bicycle manufacturer HIA Velo combines composite materials to make its products more durable.

Read MoreRucks Maschinenbau introduces continuous compression molding system for organosheets

The company claims this process offers a lower-cost option for the manufacture of organic sheets, while enabling higher pressing forces and temperatures.

Read MoreComposites recycling — no more excuses

Columnist Dale Brosius outlines six actionable levels of composites recycling that fabricators should follow.

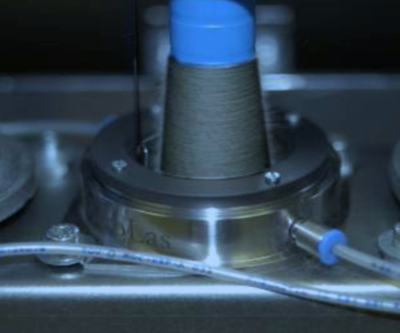

Read MoreAeroLas explores new spinning technology for thermoplastic hybrid yarn

AeroLas is working to combine recycled carbon fiber with PEEK using adapted art textile machines and a patented air guided ring spinning technology.

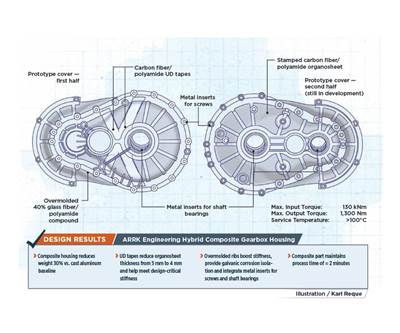

WatchProving performance in EV powertrains

Simulation-driven development replaces aluminum with thermoplastic composites in gearbox housing.

Read MoreBally Ribbon Mills acheives ISO 13485:2016 certification

Bally Ribbon Mills (BRM, Bally, PA, US), manufacturer of specialized engineered woven fabrics, has received ISO 13485:2016 certification.

Read MoreMaking better composite bikes in Arkansas

Bicycle manufacturer HIA Velo (Little Rock, AR, US), maker of carbon fiber bikes, is using a combination of composite materials to make their products more durable.

WatchMETYX USA receives ISO 9001: 2015 certification

The company’s new technical textiles production, sales and distribution facility in Gastonia, NC, US is now ISO 9001:2015 Quality Management System certified.

Read More