Weaving

Natural fiber composites: What’s holding them back?

Natural fiber reinforcements have been available for some time, but factors such as compatibility with current processes and geographic availability continue to limit widespread use.

Read MoreAutomated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

Read MoreOptima 3D launches next-generation 3D weaving machines for composites

Digital control and innovative shuttle system enable rapid parameter and sequence change for net shape preforms, billets, para beams and more.

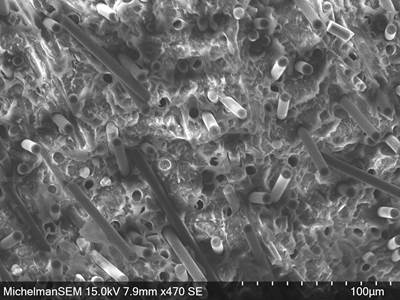

Read MoreFiber sizing, tow spreading and the quest for encapsulation

Fiber sizing is easily overlooked by composites fabricators, but it will be increasingly important to optimization of fiber performance.

Read MoreBeijing Institute of Technology leverages SwiftComp for composites research

The university is using AnalySwift’s simulation software as part of the company’s Academic Partner Program.

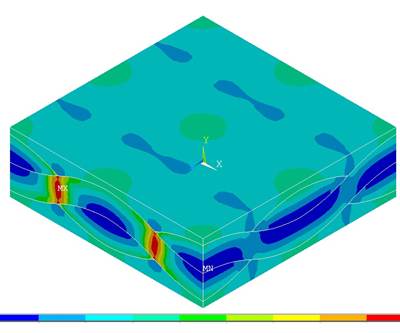

Read MoreHP-RTM for serial production of cost-effective CFRP aerostructures

Merging automotive process and tooling with aerospace quality to meet increasing production rates.

Read MorePlant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

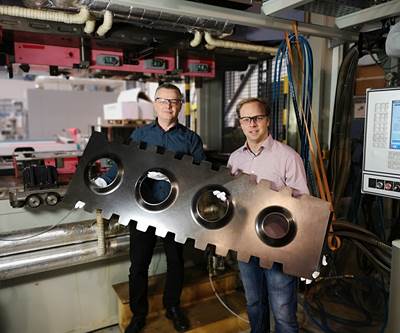

Read MoreComposites design and process engineering form next-generation truck body panels

Glass fiber/foam preform technology is key to the all-composite refrigerated truck body panels.

Read MoreHybrid resin system: Epoxy benefits, without the epoxy

Rapid cure, zero tack material ideal for automated, higher-volume production.

Read MoreTRB develops fire-resistant biocomposite door leaf

The carbon fiber-reinforced biocomposite sandwich panel features a 100% recycled foam core and has been designed for light weight and fire resistance.

Read More