Weaving

Seemann Composites Inc. acquires Materials Sciences Corporation

Composites process innovator and materials engineering innovator formally combine forces.

Read MoreCAMX 2018: Exhibit previews

If you are headed to CAMX 2018 Oct. 15-18 in Dallas, TX, you can catch a glimpse of some of the products and technologies you are likely to find on the exhibit hall floor.

Read MoreAirtech launches high temperature vacuum bagging materials for thermoplastic molding

The company has released a new high performance release film, a new sealant tape for high temperature applications and non-woven blended, fiberglass breathers.

Read MoreHexcel opens new carbon fiber plant in France

The company’s new 37-acre plant is devoted to the manufacture of carbon fiber and PAN precursor.

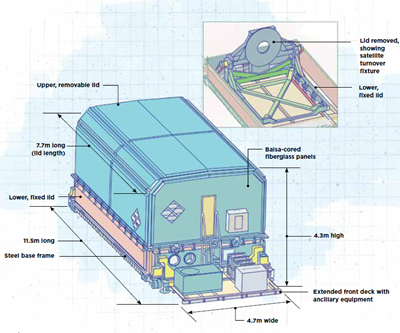

Read MoreComposite container protects satellites — on the ground

Cored composites add the strength, smoothness and portability needed for a container built to ship satellites over air, land and water.

Read MoreContinuous Fiber Manufacturing (CFM) with moi composites

Continuous fiber 3D printing using epoxy, vinylester and acrylic with continuous glass, carbon, basalt and other fibers, including deposition along nonlinear curves, is only the beginning.

WatchNASA tests foldable heat shield

NASA’s Adaptable Deployable Entry Placement Technology (ADEPT) is a foldable carbon fabric device that opens to make an umbrella-like heat shield.

Read MoreCAMX 2018 preview: Inman Mills

Inman Mills (Inman, SC, US) is introducing its Texim thermoplastic yarns and fabrics, which feature a sheath of polymer fibers covering a reinforcing fiber core.

Read MoreCAMX 2018 preview: Composite Development Centre of Québec

The Composite Development Centre of Québec (CDCQ, Québec, ON, Canada) is featuring its services, designed to help businesses and organizations that are part of the composites value chain with applied research services, technical assistance and information activities, improving the quality and performance their products.

Read MoreCAMX 2018 preview: Hexcel

Hexcel (Stamford, CT, US) is featuring one of it newest technologies, HexAM additive manufacturing technology, which combines high-performance PEKK thermoplastics with carbon fiber to produce flight-ready 3D printed HexPEKK parts.

Read More