Pultrusion

Exel Composites, Keneco Group establish joint venture for pultruded composites solutions

Kineco Exel Composites India is a composites design, engineering and production company based in Goa, India, which will serve the Indian market across transportation, wind power, infrastructure, telecommunications, aerospace and defense markets.

Read MoreComposite building systems startup launches funding round

Florida-based Galexa Homes supplies pre-engineered wall, floor and roof systems built with pultruded fiberglass composites, looks to expand and move toward robotic assembly.

WatchCAMX 2021 exhibit preview: LUM Industry

LUM Industry specializes in the design and manufacture of highly precise pultrusion dies and molds for glass, carbon fiber or thermoplastic profiles.

Read MoreBASF, L&L Products and Stellantis recognized for 2021 Jeep Grand Cherokee L lightweighting

Composite tunnel reinforcement comprised of pultruded continuous glass fiber reinforced with Elastocoat polyurethane system for 40% weight savings and improved overall performance.

Read MoreCAMX 2021: Cimbar Performance Materials

Cimbar Performance Materials’ halogen-free ATH solution for thermoset applications reduces resin costs in formulation, provides better wetout and faster line speeds and improves mold flow.

Read MoreAltair's 9th Enlighten Award winners feature vehicle lightweighting, sustainability

Annual award honors advancements in reducing the carbon footprint, mitigating water and energy consumption, promoting material reuse and recycling and applying composites for lightweighting.

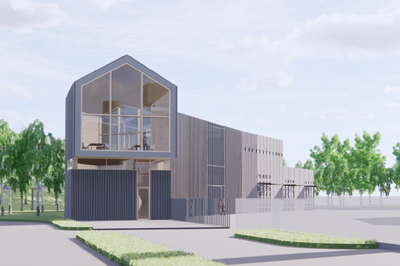

Read MoreAIMPLAS develops pultruded bio-based profiles for rural and urban development

European BASAJAUN project to optimize sustainable urban development and improve the rural economy via novel bio-based materials, products and building systems.

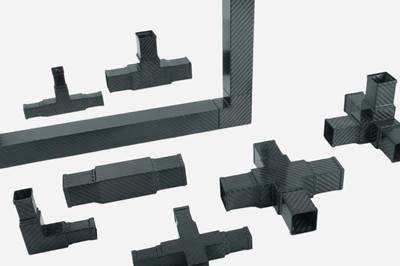

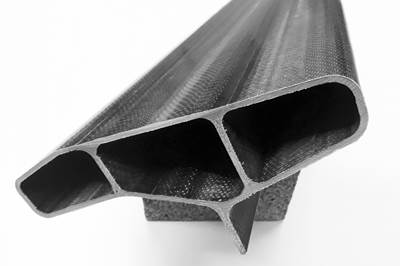

Read MoreRefitech expands RefiFLEX range, supplies pultrusion profiles for construction solutions

High-precision carbon fiber square tubes and CarboSix UD carbon fiber pultrusion profiles meet demand for lighter, stiffer, more high-performance systems.

Read MoreKent Pultrusion ships ServoPul machines to North American pultruder

Kent Pultrusion will install two of its ServoPul 2412 fully electric pultrusion lines at two North American plants.

WatchNew name for Fraunhofer lightweight construction cross-sector R&D, focus on multifunction and digitization

Research results from 2020 show breadth of applications and novel composites technologies for next-gen mobility.

Read More