Pultrusion

TNL Applied Composites Manufacturing course begins February 2023

Hybrid, seven-session class helps participants learn the tricks of different composites manufacturing technologies from wet layup to pultrusion.

Read MoreKent Pultrusion expands manufacturing facility to address the growing composite market

Doubled capacity increases the fabrication, machining and assembly capabilities for Kent’s servo motor-controlled ServoPul pultrusion lines.

Read MoreCreative Composites Group introduces product upgrades to combat extreme weather, climate change

New StormStrong FRP technologies are engineered for key infrastructure projects that need to exceed standard resiliency specifications.

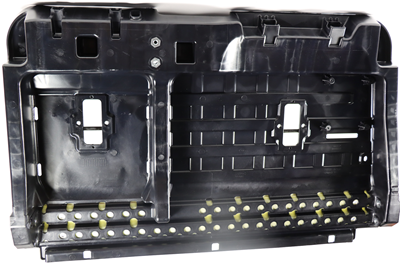

Read MoreToyota Tundra composite seatback design awarded 2022 Altair Enlighten Award

BASF, Flex-N-Gate, L&L Products and Toyota limited an all-steel assembly, cutting 60 parts down to four composite pieces for 20% weight savings.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

WatchComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

WatchMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreGurit acquires majority share in Fiberline Composites A/S

Sixty-percent share of the Denmark-based manufacturer brings pultruded carbon and glass fiber products into Gurit’s wheelhouse for wind blade production.

Read MorePultron Composites introduces the Pultrusion Guide

The free, downloadable 15-page guide is geared toward engineers and industry leaders, providing an overview on developing products with pultrusion and GFRP.

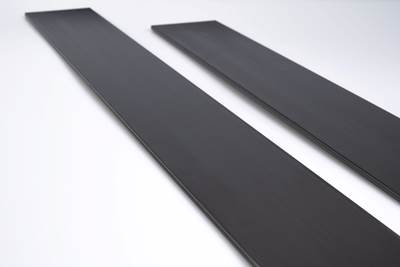

Read MoreSaertex expands production range with pultruded planks for rotor blades

SAERplanks pultruded profiles, opening new avenues in the wind industry, comprise heavy-tow carbon fibers produced using a novel hybrid resin system for reliable performance, high productivity and minimum scrap rates.

Read More