Pultrusion

Automated, continuous processes for high-volume automotive and defense components

Thunder Composite Technologies uses its automated pultrusion, RTM and other processes to produce custom-engineered composite parts for automotive and land defense vehicles.

Read MoreBASF, L&L Products collaborate on battery protection for the 2022 Ford F-150 Lightning

Continuous Composites Systems and polyurethane pultrusion system reduces crossmember size while providing strength, stiffness and rigidity to withstand high loads.

Read MorePultruded fiberglass rods enhance athletic training device

Jump Sticks, developed by Flexi-StiX LLC, combine pultruded fiberglass rods within a PVC tube to produce a semi-flexible but resistant training device for enhanced dynamic athletic training.

Read MoreFibrolux supports Polish bridge with custom pultruded deck beams

More than 16 kilometers of fiberglass-pultruded profiles double Marshal Jozef Pilsudski Bridge capacity and upgrade its durability.

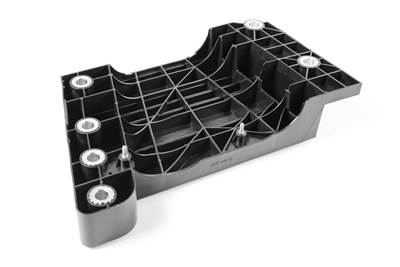

Read MoreContinuous Composite Systems (CCS) – enhanced strength and rigidity

With our Continuous Composite Systems (CCS) products and process, L&L Products can deliver a cost-effective, lightweight, ultra-high strength reinforcement solution that brings extensive engineering knowledge, advanced CAE modeling, and the ability for adhesive use in a variety of applications. (Sponsored)

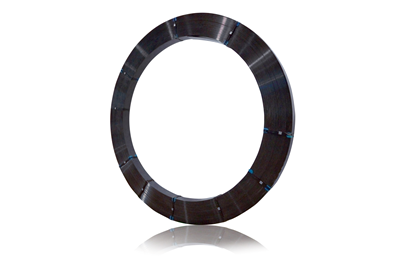

WatchHexcel partners with Metyx for high-performance carbon fiber pultrusion technology

Combined expertise within the composites industry will contribute to the manufacture of profiles made from polyurethane resin and UD carbon fiber for the wind energy market.

Read MoreStrongwell releases new product line, signs nationwide representative agreements

Strongirt, now supported and serviced globally, is an all-fiberglass, pultruded FRP continuous insulation cladding attachment support system for the commercial construction industry.

Read MoreTower Tech earns ISO 9001:2015 certification

The certification recognizes quality management systems conformance for the design and manufacture of energy-efficient FRP cooling towers with Creative Pultrusions pultruded parts.

Read MorePultron Composites advances marina construction with innovative GFRP waler

The waler incorporates a GFRP thru-rod and nut system, delivering high flex and fatigue resistance and increased environmental and aesthetic longevity.

WatchiPul pultrusion system enhances Carbon TT’s CFRP profile production for vehicle chassis

Krauss Maffei’s subsidiary, Pultrex, delivers a customized iPul pultrusion system for the production of large profile parts for around 70,000 vehicle chassis annually.

Read More