Kent Pultrusion ships ServoPul machines to North American pultruder

Kent Pultrusion will install two of its ServoPul 2412 fully electric pultrusion lines at two North American plants.

Photo Credit: Kent Pultrusion

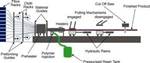

Kent Pultrusion (Kent, Ohio, U.S.), a subsidiary of Kent Automation Inc. (Kent), has recently announced that two of its patented ServoPul 2412 fully electric pultrusion lines will be installed at two North American plants. Kent Pultrusion notes that its ServoPul machines introduce servo motor and drive technology to control pulling and clamping forces and register monitored feedback to the operating system.

The ServoPul 2412 line has two 4 x 4-inch lineals as well as a pulling window that is 24 inches wide x 12 inches tall. It reportedly has a 30,000-pound pull and clamp force. A touch screen pendent system enables access to line operation. All functions of the line can be monitored and stored from the touch screen, including heaters, pull force, clamping force and product storage. The line can also be contacted via remote access for maintenance, troubleshooting and monitoring the process.

The ServoPul Pultruder includes a flying cut-off in-line saw solution for two 4 x 4-inch wide x 2-12-foot-long lineals cutting at a line speed up to 80 inches per minute.

Further, the line incorporates a pulling winch system that facilitates access for product setup. The 40,000-pound rated winch automatically raises into position where the operator can attach the 3/4-inch round cable to the glass as it is pulled through the first set of clamps to initiate the startup of new product runs.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.